The moisture content of wood pellets for optimal dynamic strength ranges from 5.5 to 8.5%. At the upper limit, the load on the press unit is noticeably lower, and the temperature of the pellet mill rollers does not exceed 85°C (185°F) for most types of raw material. With sufficiently soft and resinous raw material, it is possible to maintain moisture at the lower end, as the low load allows operation at high feed rates without overheating the ring die and rollers.

During pelletizing, a significant amount of steam is usually released from the press unit, and the raw material can lose 3-5% moisture content. Therefore, the moisture of the biomass input should be 10-12%. In certain cases, with an excessively long die, sawdust needs to be fed at 15-17% moisture content at a slow rate, "drying" the material in the pellet mill. This is permissible as a temporary occurrence during dryer adjustments and the first few hours of running-in the die, while it has increased resistance to compression due to the absence of a polished surface in the die holes.

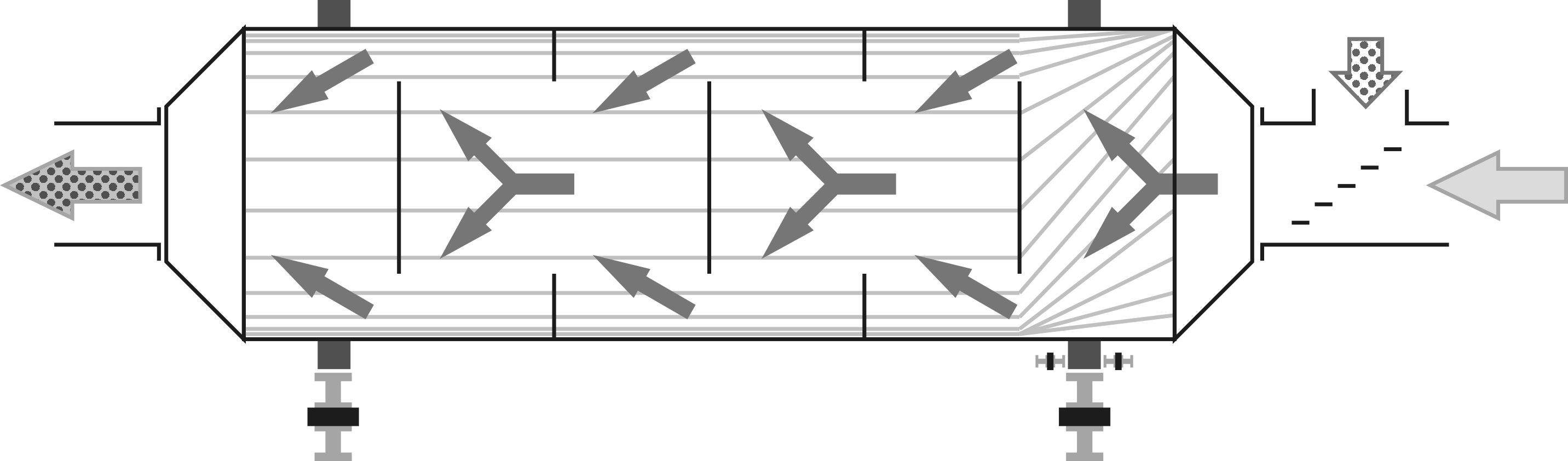

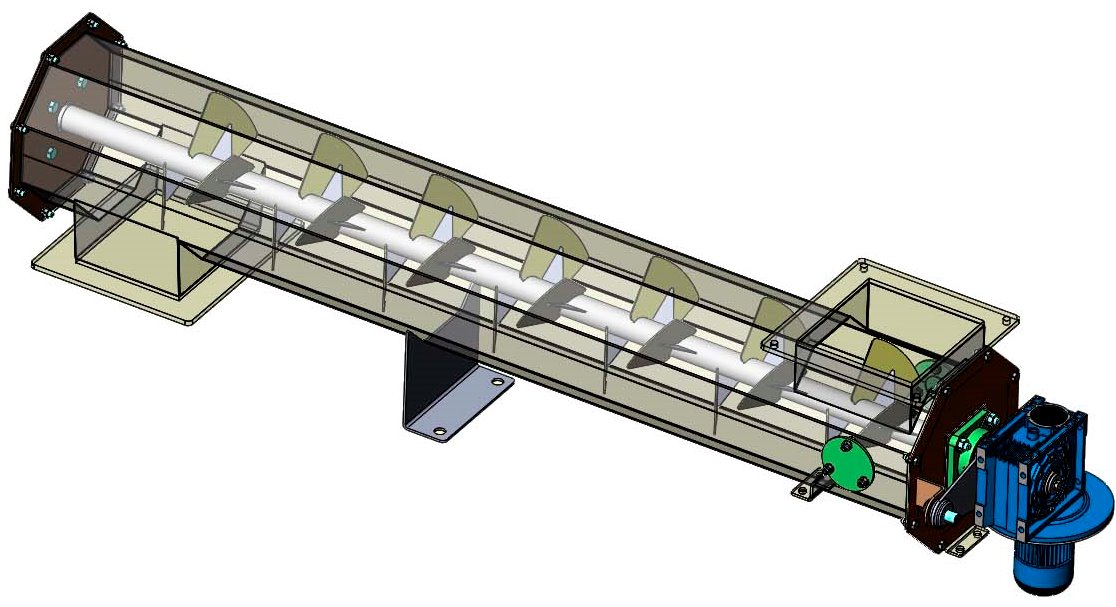

Proper moisture conditioning prior to pelletizing is carried out in a mixer-conditioner located above the pellet mill. This device is similar to a screw conveyor but has paddles attached to the shaft instead of a spiral, which simultaneously mix the raw material and move it towards the outlet. It receives either steam through a corresponding pipe or water at a pressure of 2-3 bar (29-44 psi) sprayed through nozzles installed near the intake flange. Supplying hot water at 80-90°C (176-194°F) facilitates better moisture distribution between particles, as it partially evaporates after spraying. Additionally, hot water helps to maintain the elevated temperature of the raw material after drying, reducing the load on the pellet mill. The rising steam from the press unit flows upward into the mixer-conditioner, warming and moistening the sawdust. Thus, part of the moisture manages to repeatedly enter the raw material, evaporate, and moisten the particles again before being expelled from the die along with the pellets. This circulation ensures a smoother operation of the pellet mill, transferring excess thermal energy to the incoming raw material.

Proper moisture conditioning prior to pelletizing is carried out in a mixer-conditioner located above the pellet mill. This device is similar to a screw conveyor but has paddles attached to the shaft instead of a spiral, which simultaneously mix the raw material and move it towards the outlet. It receives either steam through a corresponding pipe or water at a pressure of 2-3 bar (29-44 psi) sprayed through nozzles installed near the intake flange. Supplying hot water at 80-90°C (176-194°F) facilitates better moisture distribution between particles, as it partially evaporates after spraying. Additionally, hot water helps to maintain the elevated temperature of the raw material after drying, reducing the load on the pellet mill. The rising steam from the press unit flows upward into the mixer-conditioner, warming and moistening the sawdust. Thus, part of the moisture manages to repeatedly enter the raw material, evaporate, and moisten the particles again before being expelled from the die along with the pellets. This circulation ensures a smoother operation of the pellet mill, transferring excess thermal energy to the incoming raw material.