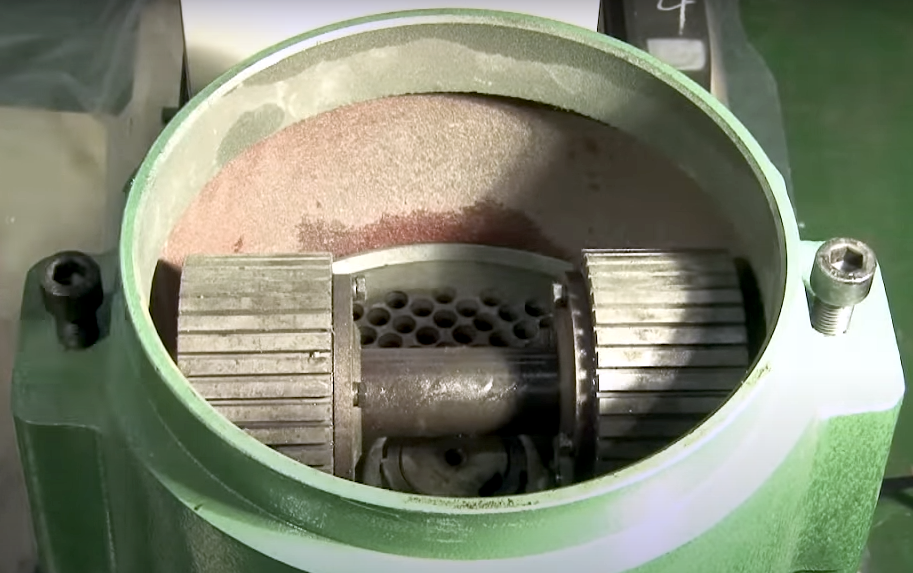

Following the positive experience of major manufacturers producing high-performance flat die pellet mills, many workshops have emerged producing flat die pellet mills with claimed capacities from 100 to 500 kg per hour (220 to 1100 lbs/h). In these models, the die is mounted on the drive shaft, while the rollers are held on a single axis, which ends rest in recesses in the housing. There are two advantages to this design. First, it allows for adjustment of the gap between the roller shell and the die during operation. A characteristic sound occurs when they touch, whereas an excessively large gap results in increased main drive current and overheating. Second, the extension of the common roller axis outside enables drilling for automatic lubrication supply, significantly prolonging the life of the bearings. Colloquially, these pellet mills are referred to as "buckets." They are appealing due to their simple design and work relatively stably on soft materials.

Following the positive experience of major manufacturers producing high-performance flat die pellet mills, many workshops have emerged producing flat die pellet mills with claimed capacities from 100 to 500 kg per hour (220 to 1100 lbs/h). In these models, the die is mounted on the drive shaft, while the rollers are held on a single axis, which ends rest in recesses in the housing. There are two advantages to this design. First, it allows for adjustment of the gap between the roller shell and the die during operation. A characteristic sound occurs when they touch, whereas an excessively large gap results in increased main drive current and overheating. Second, the extension of the common roller axis outside enables drilling for automatic lubrication supply, significantly prolonging the life of the bearings. Colloquially, these pellet mills are referred to as "buckets." They are appealing due to their simple design and work relatively stably on soft materials.

Another mixed feature is that in these pellet mills, due to the stationary roller axis and the close proximity of the shells to the housing, material spilling underneath is limited. This positively limits the load, as accumulated material in a clogged die prevents fresh inputs. The downside is this limits the throughput for soft materials and impedes even distribution across the die rows. This can be easily remedied by cutting holes opposite the rollers in the housing and welding in an angle bar. This creates an additional vertical cavity from which it is possible to supply 2 to 3 times the volume of fluffy material like shredded straw or hay.

Machines processing sawdust with low operating costs are rare, as there isn’t enough space for large bearings to handle critical loads at high temperatures. The situation is worsened by the fact that these pellet mills typically aren’t equipped with feeders and mixers, making moisture regulation challenging, turning biofuel production into a heroic endeavor. On the other hand, if the sawdust binds easily, as seen when processing larch and other resin-rich woods, finding the optimal die length can lead to relatively positive operation. Despite frequent replacement of consumables, their cost is very low, offering a chance for profitability, though the margin per unit is lower than that of large industrial pellet mills.