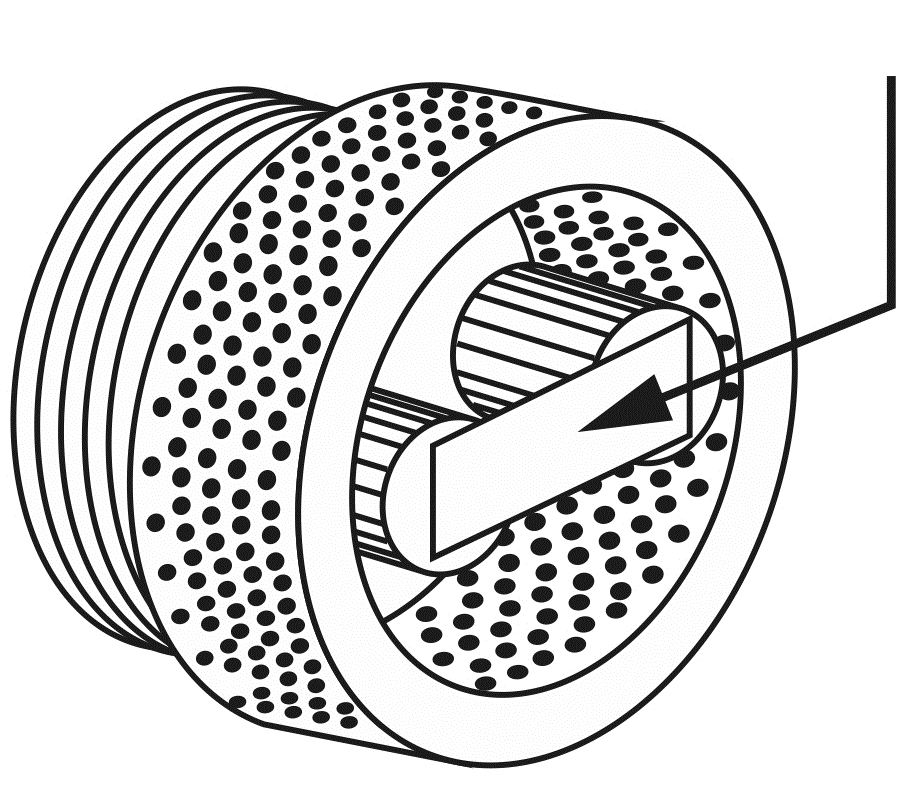

The two main types of dies are ring and flat. When using a ring die, the rollers are placed inside, and the die holes are arranged radially. The rollers push the raw material outward through the die. This design reduces the metal consumption of the press unit since the forces of the rollers balance each other, reducing or completely removing the load on the bearing between the shaft holding the die, called the flange, and the shaft with the rollers. The most common ring pellet mills have two rollers that fill the entire space inside the die and have the most powerful bearings. Pellet mills with three rollers are much less common and are mainly used for processing soft materials like animal feed, while on wood sawdust, the lifespan of the roller bearings significantly decreases.

The two main types of dies are ring and flat. When using a ring die, the rollers are placed inside, and the die holes are arranged radially. The rollers push the raw material outward through the die. This design reduces the metal consumption of the press unit since the forces of the rollers balance each other, reducing or completely removing the load on the bearing between the shaft holding the die, called the flange, and the shaft with the rollers. The most common ring pellet mills have two rollers that fill the entire space inside the die and have the most powerful bearings. Pellet mills with three rollers are much less common and are mainly used for processing soft materials like animal feed, while on wood sawdust, the lifespan of the roller bearings significantly decreases.

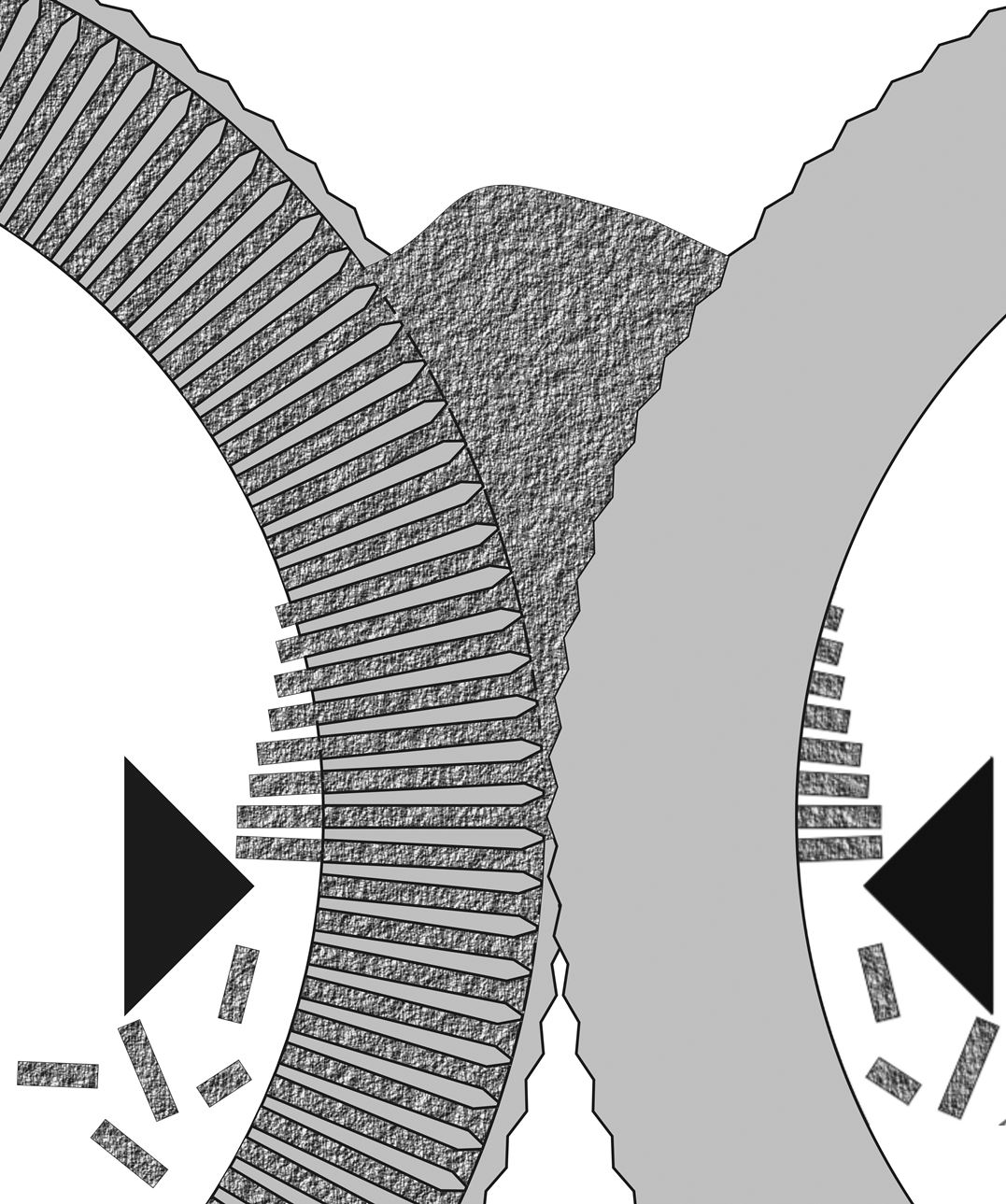

Generally, the rollers along with the holding plates and other parts remain stationary, while the die rotates around them. This is achieved in two ways: either the rollers are attached to the mill's door or to a stationary shaft running through the die's shaft. The raw material is fed under the rollers either by paddles, as shown in the image, or by two separate small diameter screws. The paddles scoop the material from the diffuser, commonly called the "hat," and direct it in a stream to the center of the die's track. With this setup, it's relatively easy to achieve even distribution of the material over the die and to adjust the pelletizing process to ensure even wear of the die. The design is complex because, with a stationary shaft inside a moving one, it's necessary to carefully calculate not only the torque of the hollow shaft, also known as the flange, but also the bending forces in case of uneven pressure on the rollers, especially under uneven and impact loads.

Generally, the rollers along with the holding plates and other parts remain stationary, while the die rotates around them. This is achieved in two ways: either the rollers are attached to the mill's door or to a stationary shaft running through the die's shaft. The raw material is fed under the rollers either by paddles, as shown in the image, or by two separate small diameter screws. The paddles scoop the material from the diffuser, commonly called the "hat," and direct it in a stream to the center of the die's track. With this setup, it's relatively easy to achieve even distribution of the material over the die and to adjust the pelletizing process to ensure even wear of the die. The design is complex because, with a stationary shaft inside a moving one, it's necessary to carefully calculate not only the torque of the hollow shaft, also known as the flange, but also the bending forces in case of uneven pressure on the rollers, especially under uneven and impact loads.

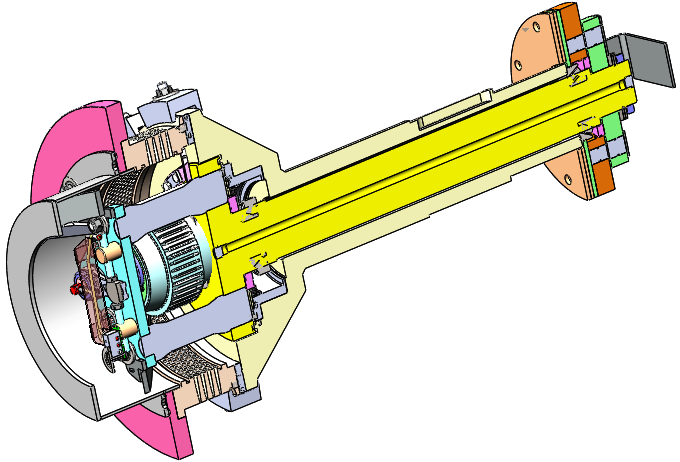

The drawing shows a greater thickness of the die's shaft between the key slot and the exit towards the die than at the back. In the bell-shaped part of the flange, most of the volume is occupied by a central bearing that absorbs all uneven impact loads. The art of designing such a unit lies in selecting the right thicknesses of parts and their load-bearing capacity. Overly rigid parts will have excessive fatigue wear, so some parts are intentionally lightened for greater elasticity under critical loads, to protect expensive and large shafts from damage.

The drawing shows a greater thickness of the die's shaft between the key slot and the exit towards the die than at the back. In the bell-shaped part of the flange, most of the volume is occupied by a central bearing that absorbs all uneven impact loads. The art of designing such a unit lies in selecting the right thicknesses of parts and their load-bearing capacity. Overly rigid parts will have excessive fatigue wear, so some parts are intentionally lightened for greater elasticity under critical loads, to protect expensive and large shafts from damage.