As previously shown, the raw material heats up to 80-90°C (176-194°F) when pressed through a die, using a significant amount of heat for warming. Therefore, to cool one ton of pellets from 85°C (185°F) to 35°C (95°F), you need to remove 1.5 (kJ/kg) x 50 (°C) x 1000 (kg) / 3600 (sec) = 20 kW of heat. In reality, more heat is removed due to the evaporation of excess moisture. The bonding of particles occurs with a guaranteed sufficient amount of moisture, meaning there is always a slight excess of moisture upon exiting the pellet mill. Freshly obtained pellets release excess moisture into the airstream and gain strength as they cool. Small cracks often become barely noticeable after the cooler. Inadequate cooling results in the top layer of pellets, about 10-15 cm (4-6 inches) thick, in a bulk bag turning back into sawdust, effectively losing the ability to sell the product at an acceptable price.

To sufficiently cool the pellets, you need to pass from 1200 to 2000 cubic meters (42,377 to 70,630 cubic feet) of air per ton of product, depending on the ambient air temperature and the design features of the pellet cooler. The second important parameter is the retention time in the cooling flow, which should be at least 15-20 minutes, depending on how the air interacts with the product. A more active airflow with less retention time can lead to small surface cracks on the pellets due to thermal shock and reduce the dynamic strength indicator during laboratory quality checks. Innovations in cooler design focus specifically on adhering to these conditions. An insufficient amount of air leads to increased temperatures in the ductwork. When the temperature exceeds 55°C (131°F), moisture condenses on the walls of the pipes, gradually forming dust clumps until the air passage is completely blocked. This negative scenario accelerates if the pneumatic transport speed is significantly lower than the optimal value for the installed pipe section.

To push the required amount of air, you need to use a fan capable of creating sufficient vacuum or pressure, equal to or greater than the total resistance of the pellet layer, ductwork with bends, cyclone, and other elements. When roughly estimating the air path with a sufficient speed for pneumatic transport of 15-20 m/s (49-66 ft/s), the resistance of a 90° bend is assumed to be 150-200 Pa, the cyclone around 600 Pa, and a duct of 10-20 meters (33-66 feet) about 150-300 Pa. Even with an empty cooler and "free" flow passage using just three pipe bends, the total pressure loss can reach 1500 kPa, exceeding the values for most low-pressure fan models like the VR 80-75. Upgrading such fans to 2500 Pa is possible by increasing the wheel diameter by 10% and installing a motor with 1.5 times more power, but exclusivity is always more expensive, and skewed blades quickly accumulate dust, and bearings are damaged due to imbalance.

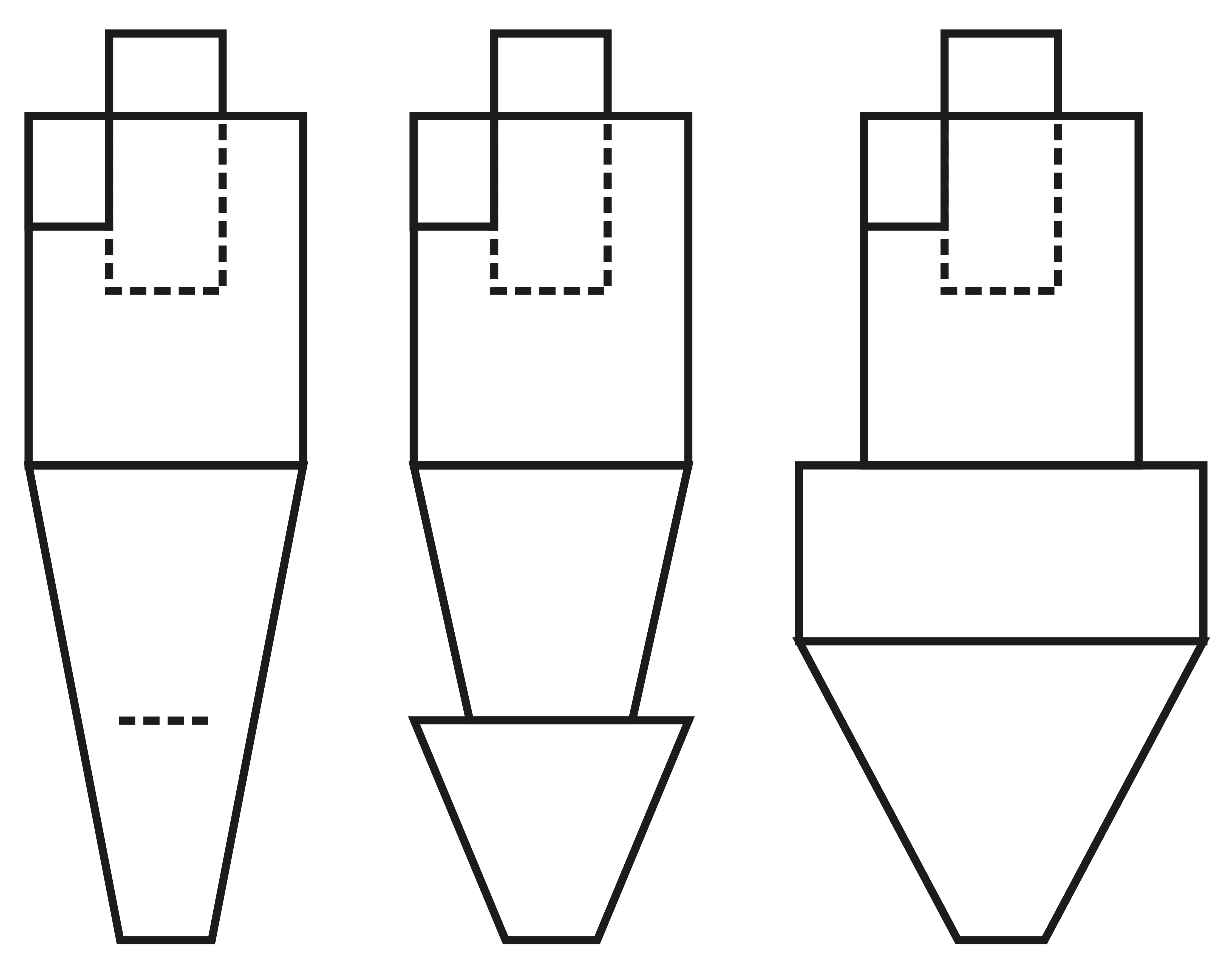

The VCP 7-40 dust fans have a more gradual curve in pressure relative to performance. This allows them to maintain high vacuum levels over a wide range of capacities. Their vacuum and performance parameters are adjusted solely by the rotational speed without changing the blade and casing design. The operating range of 2.5-3.5 kPa (0.36-0.51 psi) is built into the design. These characteristics help avoid two extremes. One is having too many chips and dust in the pellets. The reserve created by 30-50% vacuum allows for the necessary air flow to be maintained, even when the material's porosity decreases, resulting in fully marketable pellets after sieving. The other extreme is too much airflow, which causes fluidized bed spots and chips being thrown onto adjacent layer sections. This results in cooler stagnation and mass moistening, with granules getting carried into the aspiration system. Both of these phenomena reduce the plant's output and product quality. Thus, a dust fan provides steady air draft at high resistance, but cannot accelerate the flow beyond allowable limits at low resistance.

A 20-minute holding time in the airflow determines the cooler's working volume, which should be at least one-third of the hourly pellet production. Given that the bulk density of quality wood pellets is 650-680 kg/m3 (40.6-42.5 lb/ft3), at least 0.5 m3 (17.7 ft3) of working coolers' volume is required for each ton of hourly production. The "working" volume is the portion of pellets directly passed by air, excluding the volume of product in chutes, hoppers, and bunkers above the cooling zone.

A 1 meter (3.3 feet) thick layer of wood pellets causes an air pressure drop of 0.7-1.5 kPa (0.1-0.22 psi) at an average air velocity of about 0.3 m/s (1 ft/s) through the pile. The wide range is due to varying pellet lengths, reaching the upper limit with a "tablet" length of 5-7 mm (0.2-0.3 inches) and the lower limit with an average pellet length of 30 mm (1.2 inches). Assuming a cooler for 1 ton per hour as a porous-bottom container with dimensions of 1x1 meter (3.3x3.3 feet) at a half-meter (1.6 feet) layer, resistance can reach 750 Pa, which combined with other system resistances of 1.5 kPa (0.22 psi) approaches the fan's nominal value. Therefore, compact design must be abandoned, reducing the layer to 0.2-0.3 meters (0.7-1 feet).

Using a medium pressure fan to push air through a vertical column of pellets a few meters high (7-10 feet) is theoretically possible but results in uneven cooling, fluidized bed formation, and, most undesirably, local moistening of finished pellets. Organizing continuous cooler operation with a fluidized bed is more complex and may be justified energy-wise in industries like food, where pellets are 3-5 times more expensive than wood ones. But why complicate things when it's all assembled simply and cheaply with popular equipment?