Packaging is a distinct and quite complex production process. It involves dosing accuracy, package sealing, and specific stacking methods. The entire chain of actions must be time-coordinated, cost-effective, and reliable. Since we are dealing with large "batches," even small details can save significant amounts of money. For example, it is not always necessary to stick to popular polyethylene film thickness traditionally used for bags. Sometimes it is more economical to use other types of plastics, which are one and a half times more expensive but have 2-3 times greater tensile strength. This allows the film thickness to be reduced by half, resulting in substantial savings on packaging while making the bags stronger.

It is also important to be aware of minor details in advance, such as film perforation at several points on the bag to release excess air when stacking on pallets. Some types of film cannot simply be pierced with a spiked board, as they become prone to tearing. Low-density films should be punctured with a device similar to an office hole punch, which neatly cuts a hole without tearing and doesn't create a starting point for a crack in the bag.

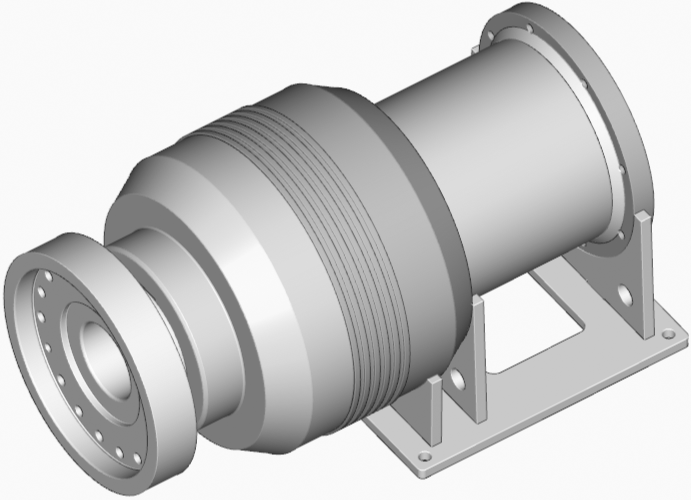

Since the pellet is fairly brittle, screw conveyor-based dosing units should be avoided to maintain its marketable appearance, even though this is a common and successful solution for pellet dosing in their subsequent processing. A rotary valve not only damages the pellet, increasing the amount of spillage in bags, but also has extremely low accuracy, as different numbers of blades can pass by the outlet during startup and shutdown. This results in unpredictable mass deviations of the product by up to 10-15%.

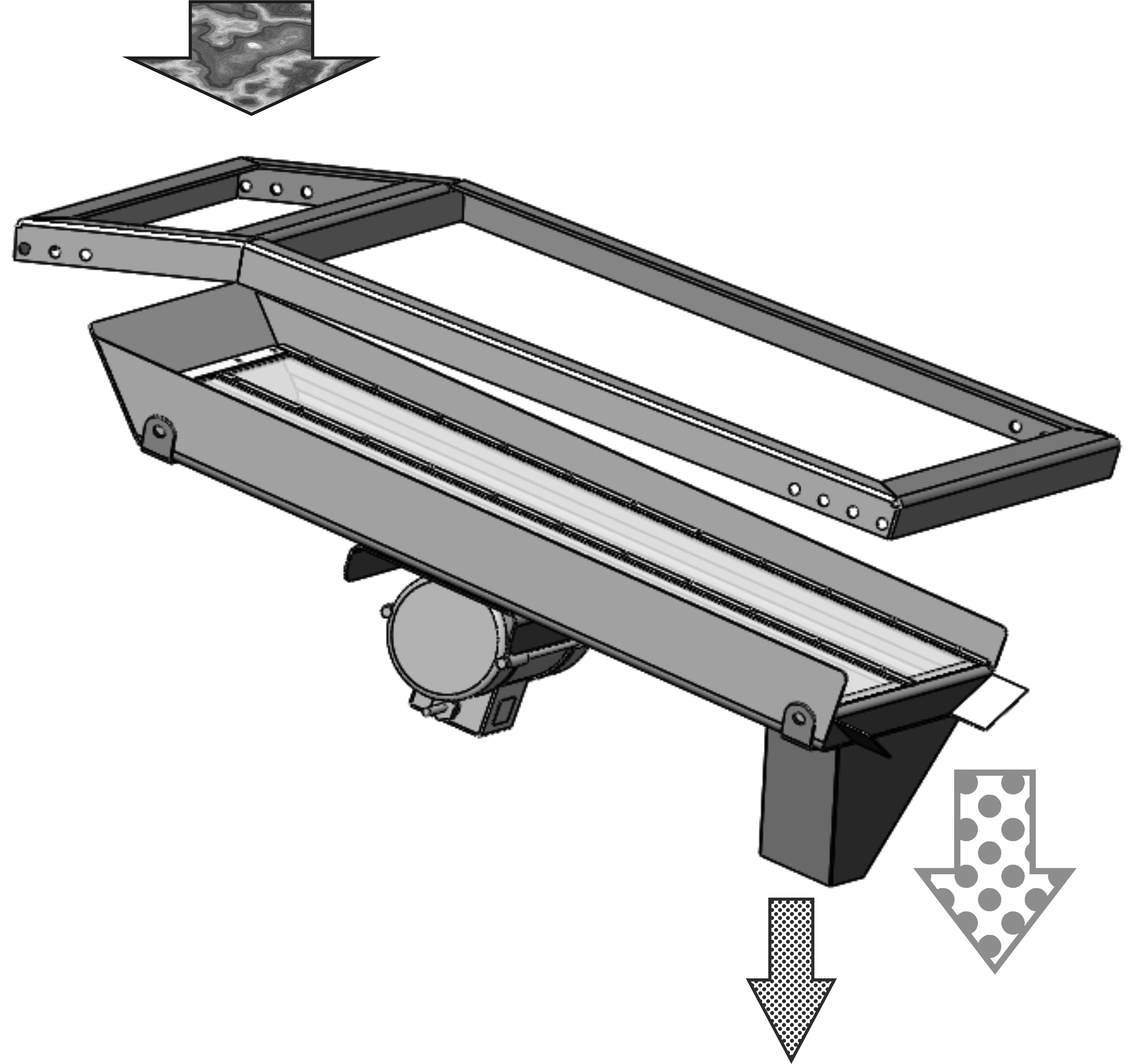

Most packaging machines use a short vibratory conveyor or sifter as a dosing device. Unlike ordinary sifters, the dosing unit employs a solenoid vibrator, which, combined with a spring-mounted tray, has its own resonant frequency. Discharge begins with an automatic signal or button press and stops with feedback from load cells continuously measuring the product's mass in the bag. When controlled by a controller, a resonant frequency in antiphase is applied for an abrupt halt, practically instantaneously interrupting vibration and allowing for highly accurate pellet dosing.

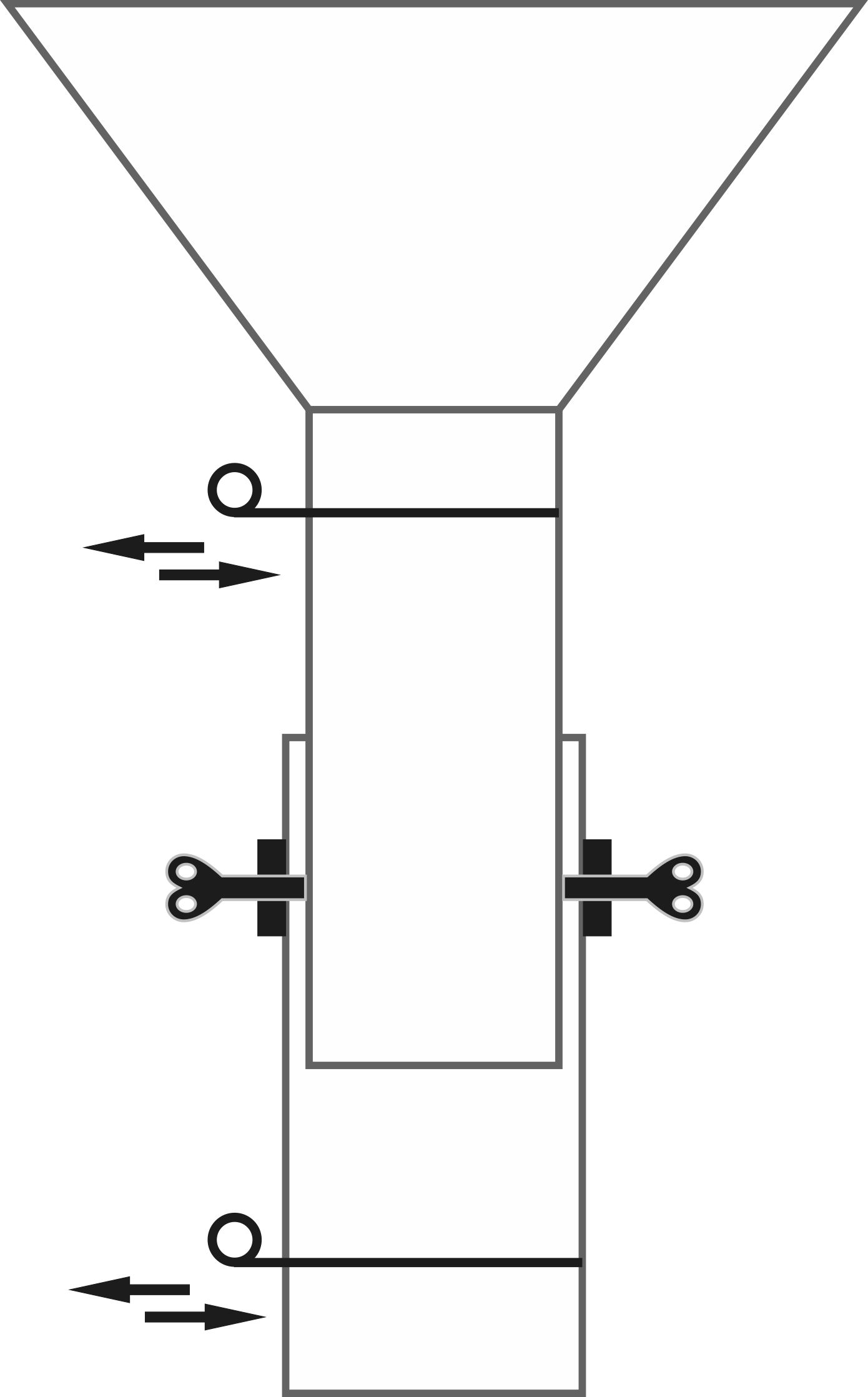

In semi-manual packaging, primitive volumetric dispensers are sometimes used. Their operation involves sequentially opening and closing intake and discharge gates, with the product volume adjusted by the distance between the valves via a telescoping body. Such a device requires periodic checking of the product mass in each portion, as bulk density can vary even within a single big bag. Installing four dispensers under a single hopper allows several workers to be tasked with packaging. This solution is justified when the packaged product portion is small in the overall production and labor is inexpensive, such as packaging cat litter into small containers of 2-3 kg (4-6.5 lbs), sold at high prices in retail chains.

In semi-manual packaging, primitive volumetric dispensers are sometimes used. Their operation involves sequentially opening and closing intake and discharge gates, with the product volume adjusted by the distance between the valves via a telescoping body. Such a device requires periodic checking of the product mass in each portion, as bulk density can vary even within a single big bag. Installing four dispensers under a single hopper allows several workers to be tasked with packaging. This solution is justified when the packaged product portion is small in the overall production and labor is inexpensive, such as packaging cat litter into small containers of 2-3 kg (4-6.5 lbs), sold at high prices in retail chains.

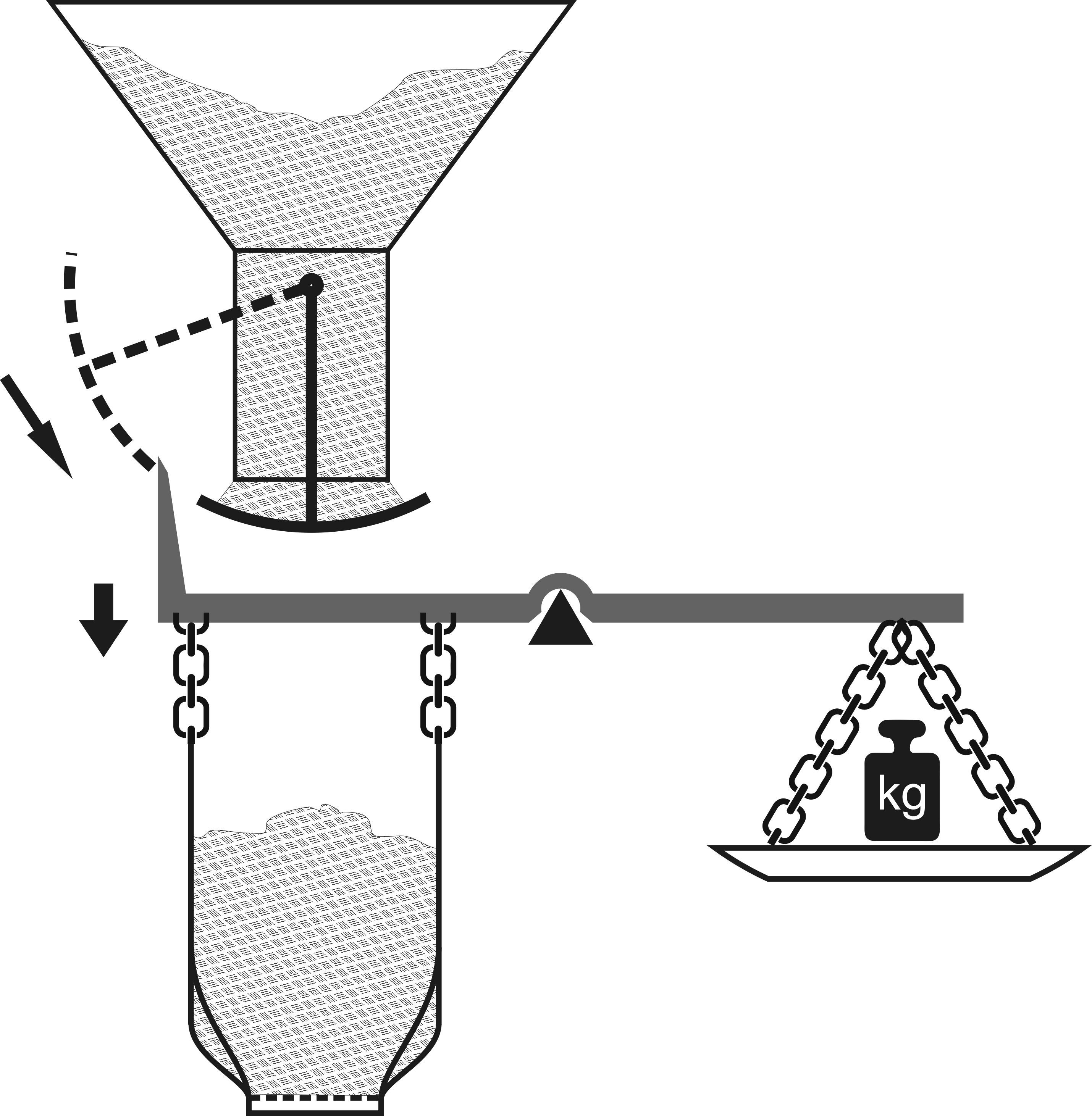

There is another method of dosing by mass using lever scales. This is the oldest method by principle and the most precise of all mechanical methods. The way it works is that the bag is attached to a swinging frame on one side, and a counterweight with the target mass is placed on the other side. A convenient counterweight is a container in which you place either another bag of pellets with the correct mass or a set of weights. Once the bag's product mass reaches the desired value, the counterweight begins to move upward, releasing the gate that closes the hopper outlet. When the next bag is set, the operator simply opens the gate and waits for it to close automatically. The undeniable advantage of this type of feeder is their speed. Unloading 15 kg (33 pounds) takes only 2-3 seconds, as the flow of pellets freely exits through a hopper throat with a diameter of 150-200 mm (6-8 inches), and the stop occurs in a fraction of a second, particularly if the gate is spring-loaded. Based on such a feeder, one can create an old-school fully automatic packager, where the automation operates on primitive relays or make it entirely mechanical.

There is another method of dosing by mass using lever scales. This is the oldest method by principle and the most precise of all mechanical methods. The way it works is that the bag is attached to a swinging frame on one side, and a counterweight with the target mass is placed on the other side. A convenient counterweight is a container in which you place either another bag of pellets with the correct mass or a set of weights. Once the bag's product mass reaches the desired value, the counterweight begins to move upward, releasing the gate that closes the hopper outlet. When the next bag is set, the operator simply opens the gate and waits for it to close automatically. The undeniable advantage of this type of feeder is their speed. Unloading 15 kg (33 pounds) takes only 2-3 seconds, as the flow of pellets freely exits through a hopper throat with a diameter of 150-200 mm (6-8 inches), and the stop occurs in a fraction of a second, particularly if the gate is spring-loaded. Based on such a feeder, one can create an old-school fully automatic packager, where the automation operates on primitive relays or make it entirely mechanical.

There are already automatic and semi-automatic weigh feeders on the market built on this principle, which have been reinvented with modern capabilities to produce devices from laser-cut bent plates.