Rollers internally resemble the hub of a trailer wheel. At the center is an axle with bearings that have an outer race holding the shell. Bearings on both sides are protected from material ingress by covers and various types of seals.

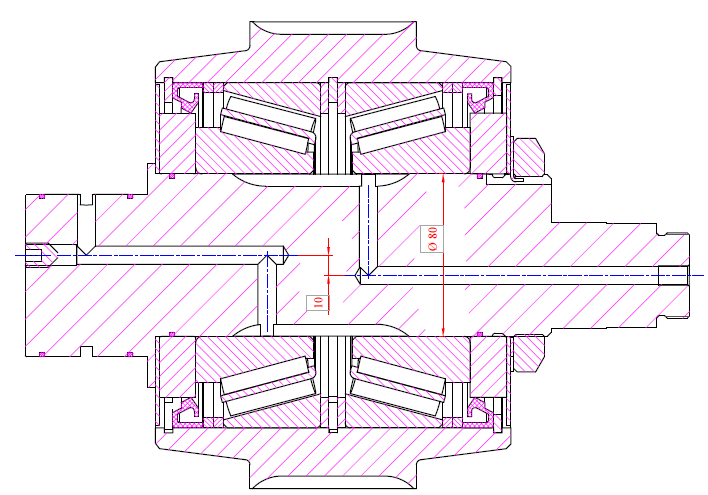

Given the low rotational speed and high load, roller bearings are used. In models where bearings are less loaded and the linear speed of the roller on the die is quite high, spherical roller bearings are used. These are found in pellet mills with a ring die diameter of 600-1000 mm (24-39 inches) with a production capacity of 3 tons per hour (6,614 pounds per hour) for wood pellets. In pellet mills with a die diameter up to 600 mm (24 inches), tapered roller bearings are more commonly used, as the ability to adjust clearances as they wear significantly extends their life. The image shows a cross-section of a roller from a GRACH-480 pellet mill. If spacer rings are removed, spherical roller bearings can be installed.

Given the low rotational speed and high load, roller bearings are used. In models where bearings are less loaded and the linear speed of the roller on the die is quite high, spherical roller bearings are used. These are found in pellet mills with a ring die diameter of 600-1000 mm (24-39 inches) with a production capacity of 3 tons per hour (6,614 pounds per hour) for wood pellets. In pellet mills with a die diameter up to 600 mm (24 inches), tapered roller bearings are more commonly used, as the ability to adjust clearances as they wear significantly extends their life. The image shows a cross-section of a roller from a GRACH-480 pellet mill. If spacer rings are removed, spherical roller bearings can be installed.

You can see a retaining ring in the groove at the center of the shell between the outer bearing races. It holds the shell in a fixed position relative to the axle, and removing it from a worn roller is not very convenient. A design with a pre-planned protrusion on the shell surprisingly turned out to be 30% more expensive, as it required a noticeably thicker blank. Therefore, it's more economical to sacrifice the retaining ring or fabricate devices for quick extraction of the outer bearing races from the shell. The simplest way to extract the race from the shell in the field is to weld a thick rod across the hole inside the race and knock it outwards.

According to engineering manuals, the bearing race that rotates in space should have a press fit. The stationary race should have a slip fit. This assembly ensures maximum bearing life. In our case, the outer race rotates with the shell. If the tension is too weak, the race may seize on the rolling elements and spin in the fitting, quickly leading to overheating and seizing of the roller. For a diameter of 170 mm (7 inches), a tension of 0.03-0.07 mm (0.001-0.003 inches) is applied, depending on the surface roughness, meaning the shell diameter is slightly smaller than the bearing diameter. Clearly, a free installation is impossible with these dimensions, so in a workshop setting for pellet production, a hydraulic press is typically used.

While hydraulics allow for roller assembly, it is not the best solution. With these forces, even with lubrication, there is a high risk of galling on the surfaces with minimal misalignment. It is much safer to use temperature differences, and there are two options. The first option is to heat the shell with an open flame to around 100°C (212°F), having set the retaining ring in advance, and then insert the outer bearing races. It’s important to heat very evenly without localized overheating to avoid tempering and damaging the shell. Careful heating can be done in a fryer with special oil, but regular mineral oil can also work. The second option is to use dry ice to cool the outer races to -80°C (-112°F) and then freely insert them into a shell at room temperature. The second method is widely used in assembly manufacturing and professional equipment repair. In both methods, after installing the first race, pause for up to 1 minute until the temperatures equalize to prevent parts from falling when turning the shell for installing the second race.

Given the complexity of bearing extraction, their lifespan in good pellet mills should exceed that of the shells, so that both parts can be replaced together. The exception is feed pellet mills, where shells can outlast several sets of bearings due to the low abrasiveness of the raw material.

The inner race of the bearing on the shaft should have a sliding fit not only for ease of adjustment and relatively easy assembly. The fact is that a stationary race will wear only on the side where the load is applied, and uneven wear by the rolling elements leads to rapid destruction. With a sliding fit, the race slowly rotates on the shaft as it wears, consistently exposing a fresh surface to the rolling elements. Since the contact area of the rolling elements is much smaller than the contact between the inner race and the shaft, shaft wear is not critical. Considering the hardening of shafts and the presence of lubrication between them and the race, they should last at least 10 bearing lifespans. This should be considered when stocking consumables, including spare rollers to reduce downtime during their replacement.

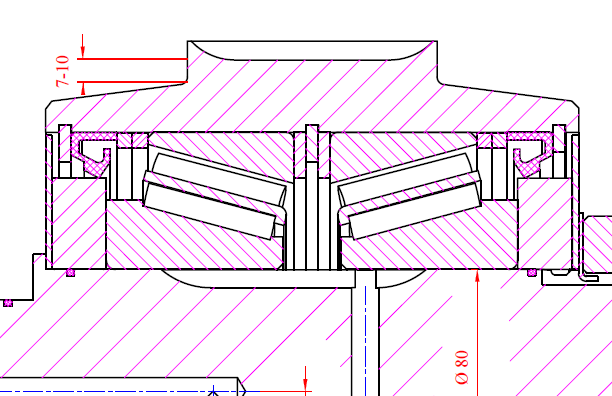

The design of shells includes conical-shaped side parts so that as the die wears and approaches them, it cannot roll up any ridges of sawdust and press against the rollers, creating a parasitic load. The transition from the shell track to the side should be at least 7 mm (0.28 inches) from the edge of the track in a worn state to ensure elimination of this effect.

The design of shells includes conical-shaped side parts so that as the die wears and approaches them, it cannot roll up any ridges of sawdust and press against the rollers, creating a parasitic load. The transition from the shell track to the side should be at least 7 mm (0.28 inches) from the edge of the track in a worn state to ensure elimination of this effect.