The second end of the stationary shaft is usually attached to the pellet mill body through a protective device equipped with shear pins. Under excessive load, the pins break along a pre-established groove, the stationary shaft starts rotating with the die, and the load is removed from the equipment. Since the stationary shaft exits the pellet mill, it’s fairly easy to supply lubrication to the rollers through it, which compensates for the overall complexity of the mechanism. It's essential to pay attention to the length of the pins, the thickness of the hardened bushings that hold them, and the strength of the protective device's flanges. Bushings with a wall thickness less than half the pin's diameter wear out quickly, and when the length-to-diameter ratio of the pin is less than 4:1, it tends to skew under critical loads and can eventually shear off the eyes where the bushings are inserted.

The second end of the stationary shaft is usually attached to the pellet mill body through a protective device equipped with shear pins. Under excessive load, the pins break along a pre-established groove, the stationary shaft starts rotating with the die, and the load is removed from the equipment. Since the stationary shaft exits the pellet mill, it’s fairly easy to supply lubrication to the rollers through it, which compensates for the overall complexity of the mechanism. It's essential to pay attention to the length of the pins, the thickness of the hardened bushings that hold them, and the strength of the protective device's flanges. Bushings with a wall thickness less than half the pin's diameter wear out quickly, and when the length-to-diameter ratio of the pin is less than 4:1, it tends to skew under critical loads and can eventually shear off the eyes where the bushings are inserted.

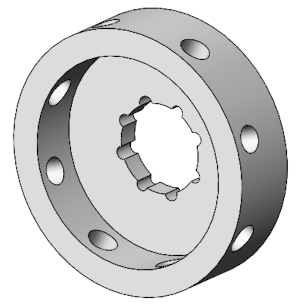

This unit can be relatively easily improved to enhance reliability and increase its lifespan several times over. Instead of using eyes, the parts are made with solid rims featuring 8 or 10 holes for bushings with pins. This not only adds rigidity to the connections but also allows for the installation of bushings in spare holes. The cost increases by approximately 1.5 times, but it seems a quite acceptable solution, eagerly embraced by customers.

This unit can be relatively easily improved to enhance reliability and increase its lifespan several times over. Instead of using eyes, the parts are made with solid rims featuring 8 or 10 holes for bushings with pins. This not only adds rigidity to the connections but also allows for the installation of bushings in spare holes. The cost increases by approximately 1.5 times, but it seems a quite acceptable solution, eagerly embraced by customers.

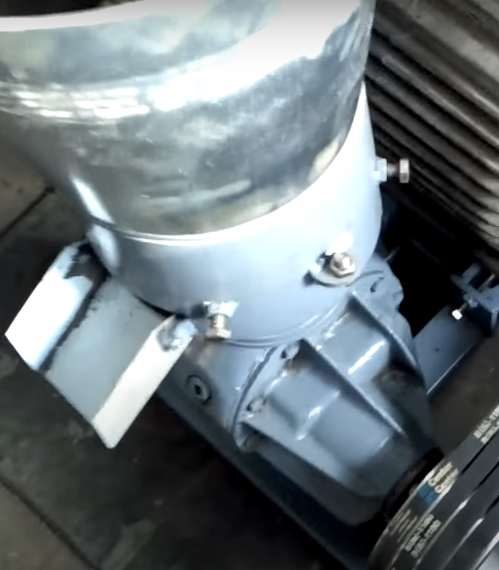

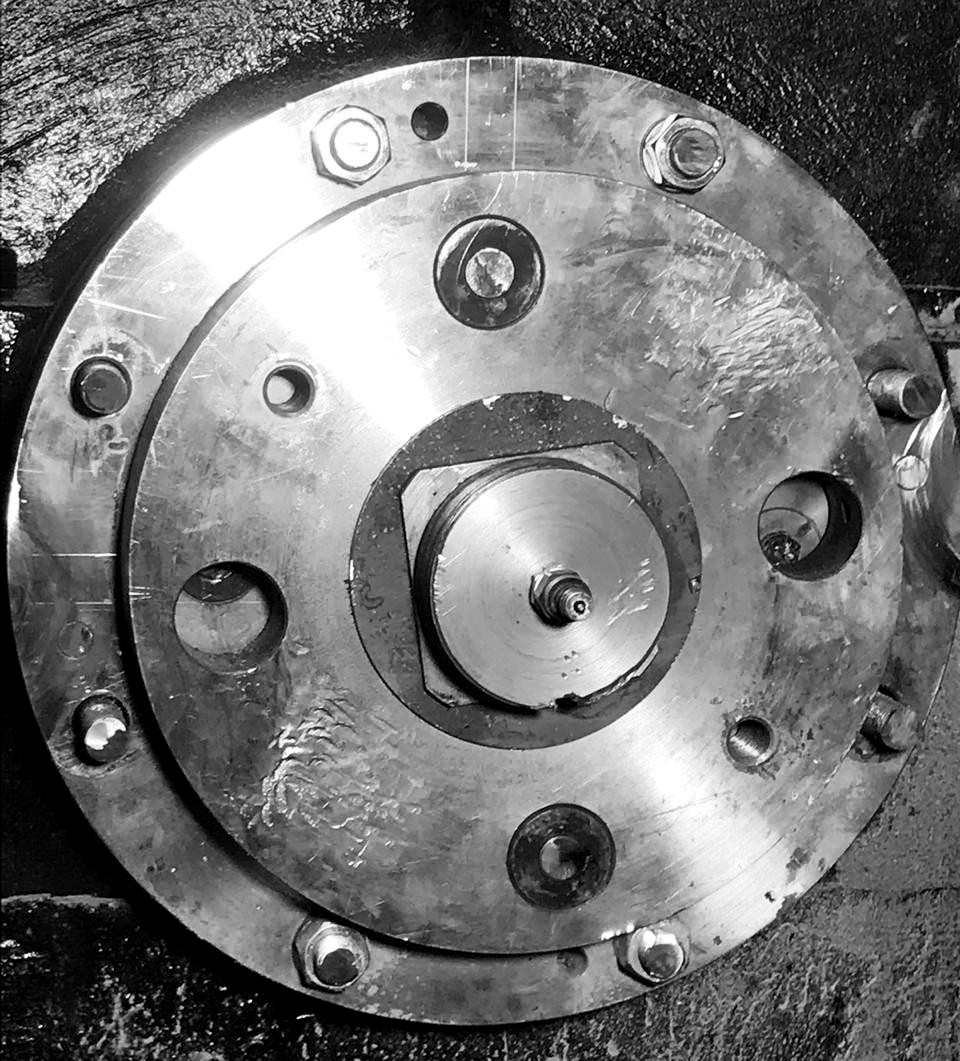

Another way to make the protective device exceptionally reliable with a significant margin for restoration is to make it in the form of two flat discs with holes. In this design, the shear pins will be positioned not radially but parallel to the shaft axis. Such flanges can be mounted directly onto the cover of a standard gearbox. There is enough space on the flange for 4 or 8 holes for bushings with pins. With this setup, worn holes can be bored 1mm wider in diameter using larger bushings, extending the unit's lifespan beyond that of the pellet mill itself. The photograph also shows that for connecting the stationary shaft to the small flange of the protective device, a square section is used instead of splines. This connection is very easy to repair with available tools. The shaft can be built up with steel using arc welding, then the surface can be finished with a flap disc for the flange. Alternatively, send the shaft to the nearest auto repair shop where the surfaces can be machined to size in one day, making the procedure significantly cheaper than purchasing a new shaft. Spline connections usually cannot be restored and require much higher manufacturing precision.

Another way to make the protective device exceptionally reliable with a significant margin for restoration is to make it in the form of two flat discs with holes. In this design, the shear pins will be positioned not radially but parallel to the shaft axis. Such flanges can be mounted directly onto the cover of a standard gearbox. There is enough space on the flange for 4 or 8 holes for bushings with pins. With this setup, worn holes can be bored 1mm wider in diameter using larger bushings, extending the unit's lifespan beyond that of the pellet mill itself. The photograph also shows that for connecting the stationary shaft to the small flange of the protective device, a square section is used instead of splines. This connection is very easy to repair with available tools. The shaft can be built up with steel using arc welding, then the surface can be finished with a flap disc for the flange. Alternatively, send the shaft to the nearest auto repair shop where the surfaces can be machined to size in one day, making the procedure significantly cheaper than purchasing a new shaft. Spline connections usually cannot be restored and require much higher manufacturing precision.