Although the process of biomass pyrolysis is often associated with furnace systems or separate chemical productions, it shares a common feature with the drying process – heating is used to remove decomposition products in the form of steam and various combustible gases from solid raw materials. A simple example is the two-stage processing of raw material in rotary drum dryers. In the first stage, the drying is done to 3-5% moisture content with a high flow of thermal agent, then the raw material goes to the second rotary drum where the flow of thermal agent is 3-5 times less, but its temperature is significantly higher. The material quickly heats up from 70°C (158°F) to 160-200°C (320-392°F), and then pyrolysis becomes exothermic and in a well-insulated drum, the process continues on its own. With a low flow over the material, the drum's design resembles an inverted screw, where spirally arranged shelves help move the material outwards. The gas produced by pyrolysis is partially directed into a separate heat generator to create primary heating, while the rest either goes into the heat generator of the first dryer or is simply burned in a separately arranged flare stack.

Wood pyrolysis usually proceeds at a rate of 1mm per minute with active surface heating by flame, meaning for a board piece 50mm (2 inches) thick, it takes about half an hour to completely turn into charcoal, when the process front reaches the middle from both sides. This method is unsuitable for rotary drums, hence the thermal agent usually does not exceed 800°C (1472°F) and pyrolysis occurs noticeably slower given the time spent on preheating. Additionally, as particle size decreases, the thermal conductivity of the raw material significantly drops, so grinding chips to sawdust for pyrolysis is not advisable, as processing time doesn’t change much but depends more on nozzle configuration and mixing activity. Conversely, for a stable pyrolysis process, the sawdust is usually densified into pellets with a diameter of 14-20mm (0.55-0.79 inches). Compacting the wood raw material increases thermal conductivity, accelerating the heating and pyrolysis process. In general, loose material pyrolysis takes from 10 to 30 minutes, and the product loses about three times its mass.

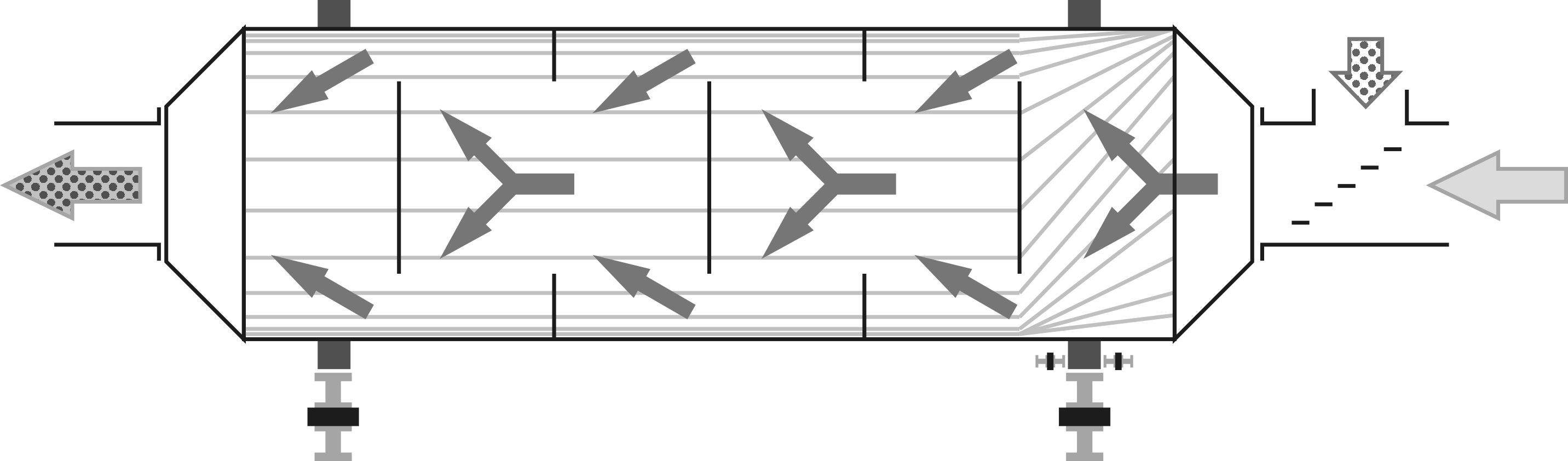

Operating the drum at working temperatures of 800-900°C (1472-1652°F) results in rapid material degradation, fatigue cracks, and burnout. Using a heated screw conveyor for pyrolysis is more practical. The screw itself is spiral, which almost eliminates the sticking of raw material, while the pipe-like body and spiral are inexpensive consumables.

Operating the drum at working temperatures of 800-900°C (1472-1652°F) results in rapid material degradation, fatigue cracks, and burnout. Using a heated screw conveyor for pyrolysis is more practical. The screw itself is spiral, which almost eliminates the sticking of raw material, while the pipe-like body and spiral are inexpensive consumables.

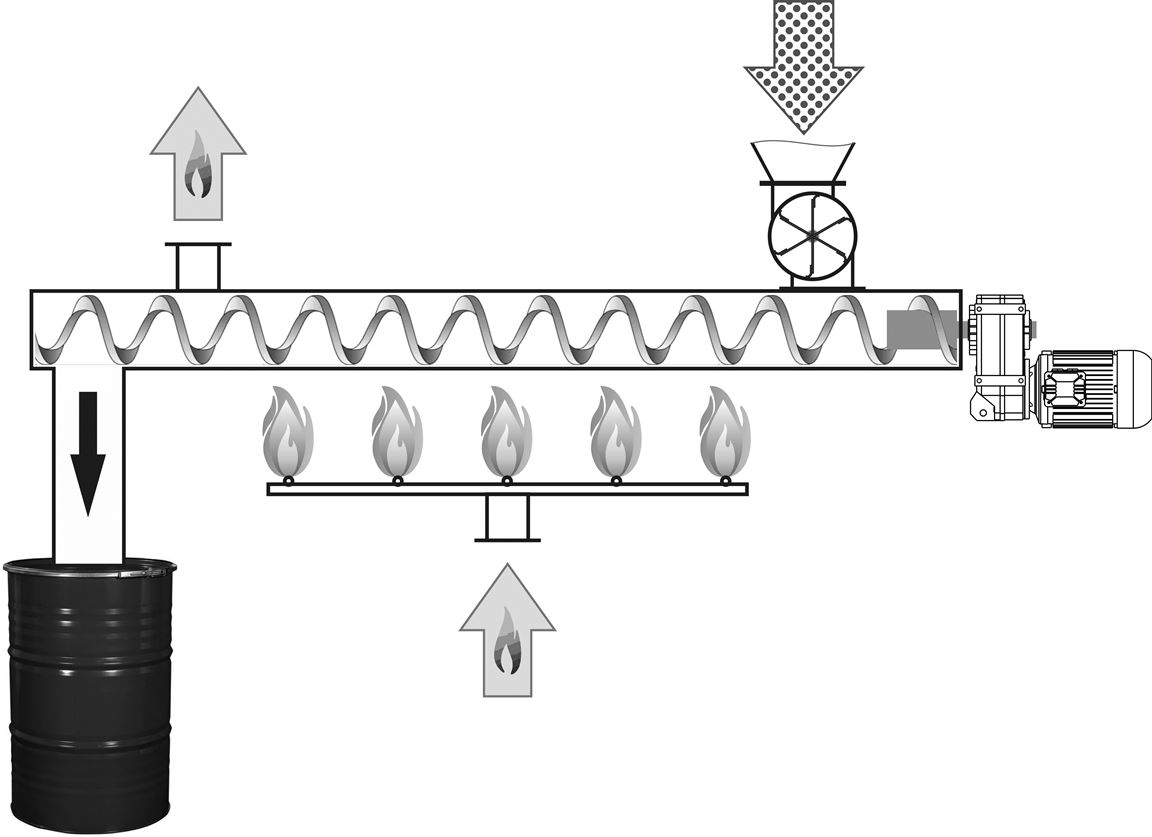

Sawdust or chips are fed into the screw through a sluice gate to minimize oxygen entry into the heating zone. As the spiral progresses, it mixes the raw material and actively heats it from the conveyor walls. Usually, the process starts with burners on liquefied gas or liquid fuel. When pyrolysis enters the active phase, the released gases are vented through a top outlet and fed into a lower ramp with a row of burners. Once the system reaches operating mode and is fully heated, there is enough pyrolysis gas for heating, and the additional fuel source is turned off.

At the exit of the pyrolyzer, an activation zone is sometimes installed where the charcoal is processed with steam to produce activated carbon with high porosity. If the goal is to obtain charcoal fuel, a sufficiently long screw conveyor is installed to cool down the charcoal granules. Discharge should occur into a hermetically sealed container or bunker because even non-activated charcoal has such a large surface area that it spontaneously ignites in the open air within 10-30 seconds. It is much safer to immediately mix a cooled product with starch or molasses in an amount of 10-15% of the mass and transform it into pellets using a ring die pellet mill or send it to a roll press briquette maker. For granulation, first mix with a binder in dry form for more even distribution, then moisten the prepared mixture with nozzles just like sawdust. The water consumption is 100-150 liters per ton of the final product. Charcoal granule also needs a cooler. Active air cooling of the pellets usually does not lead to spontaneous combustion since the binder closes the pores, and pressing increases the density by 5-7 times, leaving too few pores for self-ignition. In case of accidental stoppage of starch supply, the load on the pellet mill rises sharply, and such a situation cannot go unnoticed by the operator, therefore the likelihood of a small amount of spontaneously combustible product entering the cooler remains. Thus, the granulation section must provide for emergency dumping of the product from each unit into a single discharge conveyor equipped with a water supply to extinguish smoldering granules or pellets.

The safest way to deactivate coal is stabilization, which involves continuously supplying small portions of air while actively mixing and removing heat through the shell of the mixer or an externally cooled screw conveyor. By strictly controlling the supplied portions of air, distributing it through a ramp and a row of nozzles located along the mixer, a safe product is obtained that can be transported in regular sealed containers. A more labor-intensive stabilization option is packaging in buckets or drums with latch lids, which do not provide complete airtightness. Gradual absorption of oxygen first decreases the volume of gases inside the container, and upon heating, the volume increases again with part of the gases exiting, then it cools down again, drawing in a fresh portion of air. This cyclical breathing over 2-3 weeks leads to the complete stabilization of the coal and provides an idea of the necessary safe air quantities for calculating the continuous mixer.

For a capacity of 500 kg/h (1100 lbs/h), the pyrolysis plant consists of two screw conveyors with a diameter of around 600 mm (24 inches) and a length of 10-12 meters (33-39 feet), placed side by side in a horizontal plane. It can fit into a 40-foot container and be autonomously used in immediate proximity to a wood waste dump. To increase productivity, it is more practical to simply increase the number of screw conveyors because increasing the diameter would lead to reduced efficiency or inadequate residence time. Using thinner pipes and spirals is also impractical as this would lead to significantly greater metal consumption and manufacturing cost, as well as complexity in operation and maintenance.

When briquetting with a roll press, to reduce costs, 10-30% of a mineral binder like cement, clay, or gypsum is added. Unlike pelletizing, forming briquettes does not generate significant heat, so the product requires drying to gain sufficient strength. For this purpose, a standard pellet cooler can be conveniently used, but instead of pulling air out, pre-heated air at 60-80°C (140-176°F) is forced into the cooler. Coal is very abrasive, so opting for a louver cooler is better, as the counterflow type can have issues with its unloading system. A louver cooler is placed in a casing where air enters through a heat gun or heater and is extracted in the usual way for the unit. The cooler should have a bottom exit opening of at least 400x400 mm (16x16 inches) to prevent briquettes, which can reach sizes of 70 mm (3 inches), from getting stuck.

Chain conveyors with inserts made of bent perforated sheets are also used to dry coal briquettes by enclosing them in a casing and using a standard blade fan to push air through. These solutions can be justified if a conveyor is available and can be modified cheaply when production volumes are several hundred kilograms (300 pounds) per shift. For a throughput of 500 kg (1100 pounds) per hour, a cascade of such conveyors forms a drying conveyor, which is many times more expensive than a pellet cooler, more challenging to maintain, and occupies much more production space.