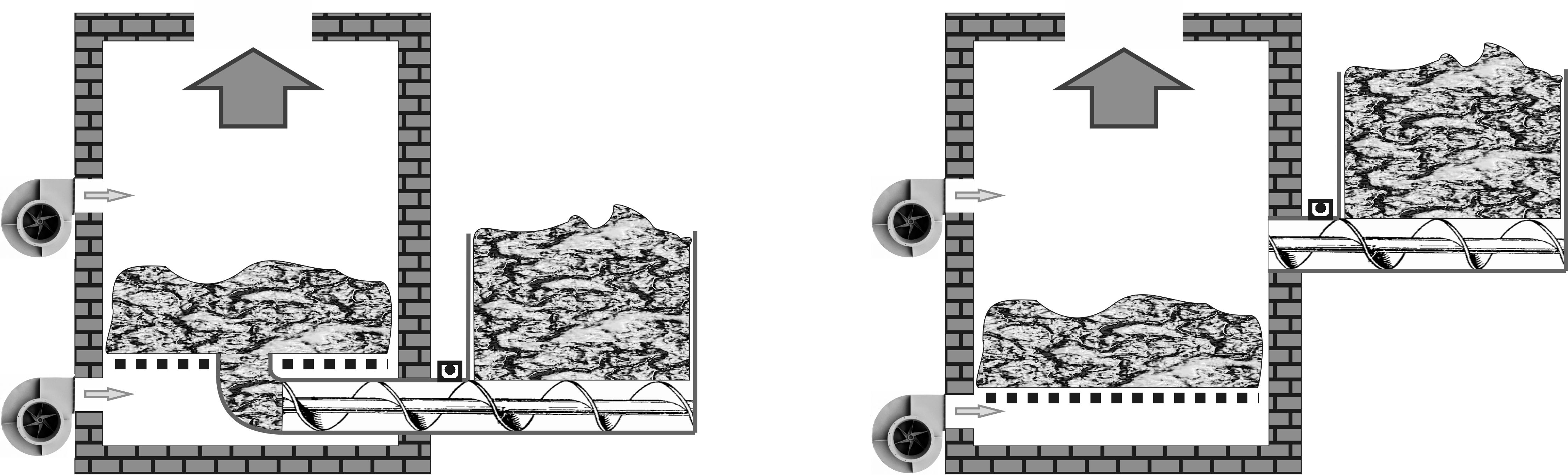

In a pyrolytic heat generator, combustion occurs in a relatively thick layer of chips, which are fed by an auger directly through the wall or from below between the grate bars.

Active smoldering takes place above the grate surface, where air is supplied. Pyrolysis products like carbon monoxide, vapors of various organic substances, and water rise into the remaining chip layer, where heavy fractions temporarily condense and are retained, while lighter ones reach the surface and burn in the supplied secondary air. The flame above the fuel surface, while producing active heat radiation, typically does not allow moist chips to burn intensely as they are covered by new layers of fuel.

Active smoldering takes place above the grate surface, where air is supplied. Pyrolysis products like carbon monoxide, vapors of various organic substances, and water rise into the remaining chip layer, where heavy fractions temporarily condense and are retained, while lighter ones reach the surface and burn in the supplied secondary air. The flame above the fuel surface, while producing active heat radiation, typically does not allow moist chips to burn intensely as they are covered by new layers of fuel.

This combustion method requires two air supply points: under the grates to regulate the intensity of pyrolysis, and into the furnace above the chips for burning gases. The furnace usually has a vertical cylindrical shape, so the upper fan supplies air tangentially, enhancing mixing and gas combustion with enough oxygen. Additionally, the rotating vortex helps to throw larger embers to the wall and retain them in the furnace, so pyrolytic heat generators often operate without a spark arrestor system. Sometimes the unit is divided into two separate blocks: one generates pyrolysis gas, and the other burns it. This setup is much shorter and easier to install, but the transfer of hazardous gases between two large equipment parts can frighten buyers. On the other hand, any heat generator using biomass as fuel can emit large amounts of carbon monoxide, which could enter the workshop if the operator makes a mistake.

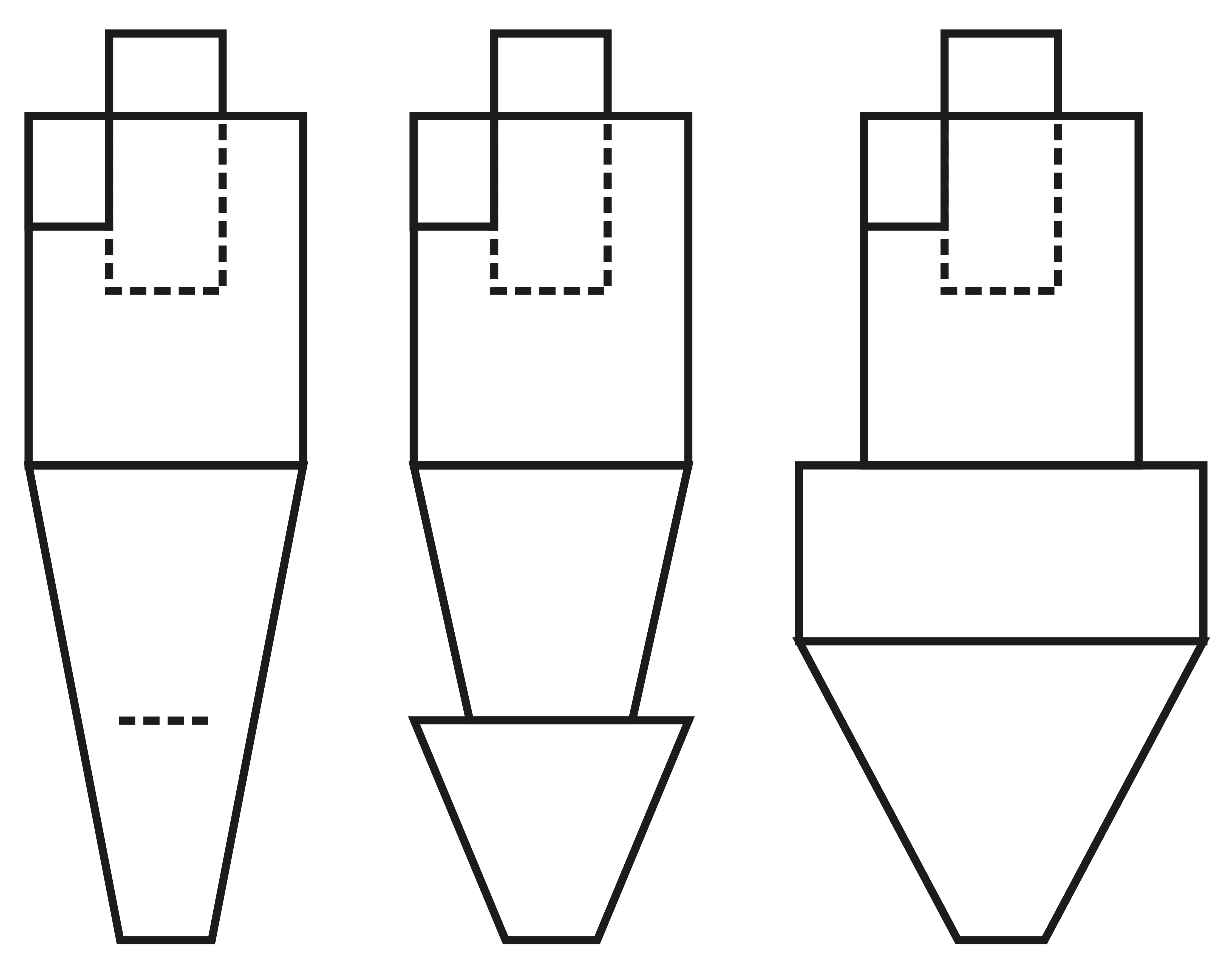

The lower part of pyrolytic heat generators is often designed as an inverted truncated cone. This construction is similar to gas generator systems for cars that used wood as fuel in the mid-20th century. Air is supplied to the upper part of the cone and moves along the inner surface in the smoldering area. The lower part of the truncated cone is a grate onto which fully carbonized fuel gradually slides. Thus, heavy pyrolysis fractions initially formed travel through hot coals with a slight excess of oxygen and decompose into small molecules of so-called generator gas, mainly consisting of carbon monoxide and hydrogen. Additional air is supplied under the cone where the normal combustion of gases occurs. This design is more complex and expensive, but a small air supply over the raw material mass slowly penetrates to capture gases, preventing accumulation and reducing the risk of explosion. The improved composition of pyrolysis gas burns more efficiently and causes less pollution in pipes and chimneys.

Lower feeding might cause chip blockage at the body turn and maintenance difficulties, but the auger is protected from high temperatures and actively cooled by fresh portions of chopped wood. Feeding above the grates almost always leads to ignition inside the auger, requiring regular water application between the feed hopper and furnace wall. This is just the tip of the iceberg, posing a greater risk. A temperature sensor is typically installed on the auger body, activating a water supply solenoid valve. When the heat generator is stopped, it's important to keep the system powered, or smoldering reaches the fuel hopper, causing a fire. During normal operation, wetting is uneven, and excess water sometimes runs off the auger onto hot walls and grates, causing thermal shock and damage. In severe frost conditions, ensuring continuous water supply and preventing auger freezing adds more challenges.

The main disadvantage of a pyrolytic heat generator is the need to maintain a relatively thick layer or pile of wood chips in the furnace for stable operation. During an emergency shutdown, this means a large quantity of gases is released without active ventilation. This can extinguish the flame and result in an accumulation of an explosive gas mixture. If there is a sufficiently large startup pipe and a damper to isolate the heat generator's chamber from the dryer, smoke escapes through this pipe and gases are carried away by the wind. Otherwise, pyrolysis gases fill the drying drum, air ducts, and cyclones, and as the fuel burns out, a volumetric explosion could occur, possibly destroying the building and causing casualties among personnel. The fuel layer is chosen based on its moisture content and calorific value and monitored with photo sensors. If there is a malfunction in automation or an operator error, where increased power is attempted by simply adding more fuel, this can lead to furnace overfilling. Initially, due to a lack of oxygen, a large mass almost smothers, and then active smoldering begins, releasing a far greater amount of combustible gases than the system was designed for. The entire drying process can then turn into a fire-breathing dragon.

The second disadvantage is the need for regular stops for cleaning. Even grates with relatively large spacing between bars typically get clogged with ash after 4-5 days of operation, and cleaning underneath becomes insufficient for full operation. Therefore, the production line must be completely stopped, and the furnace cooled and cleaned of all accumulations.

The advantage of such a heat generator is its low cost and versatility with the ability to operate in automatic mode. The simple furnace design is fairly resistant to multiple starts and cool-downs. The refractory lining in any heat generator is bonded with a thin layer of mortar, a special clay solution. The temperature of 400°C (750°F) is critical, as the mortar loses strength, and thermal expansion gives the bricks some mobility. Therefore, every crossing of this temperature slightly breaches the integrity of the lining. Over time, the settling of bricks leads to cracking, partial falling out, and eventually, the need for complete renewal. Hence, standard documentation typically specifies not only the service life but also a limit on the number of startups, usually about 100. This means that even with perfect handling, with weekly stops, the lining will last a maximum of two years before major repairs are needed.

An unpopular but effective method for laying refractory brick is to do it without mortar. If the bricks have stable geometric dimensions, they can be tightly laid together without bonding, even with arches and vaults, and behave quite stably if constrained by a casing or tightened with steel bands. The steel casing ensures tightness, holding the bricks in place so no sudden flashing or flames burst through gaps even if there is a sudden loss of vacuum within the furnace.