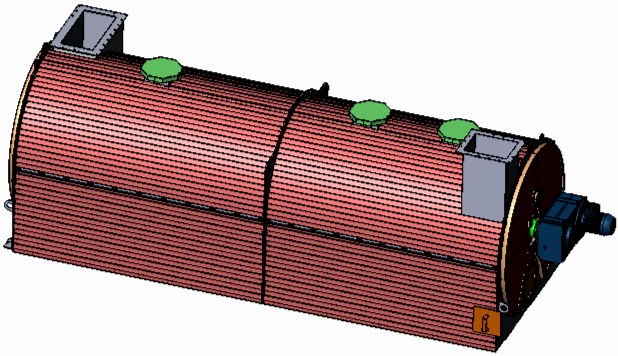

The fourth variant of a dryer with a stationary body and rotating rotor is the roaster. The primary and popular use of this unit is roasting and steaming grains before oil extraction. However, modifications with lighter stirrers and increased vessel areas are successfully used for drying various bulk materials.

The fourth variant of a dryer with a stationary body and rotating rotor is the roaster. The primary and popular use of this unit is roasting and steaming grains before oil extraction. However, modifications with lighter stirrers and increased vessel areas are successfully used for drying various bulk materials.

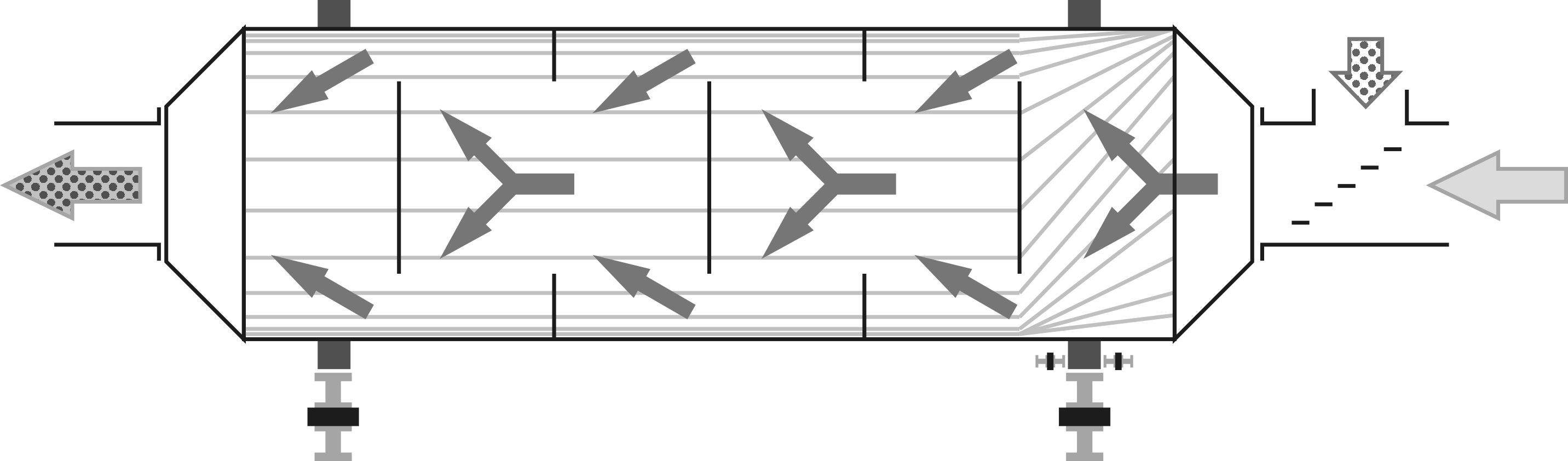

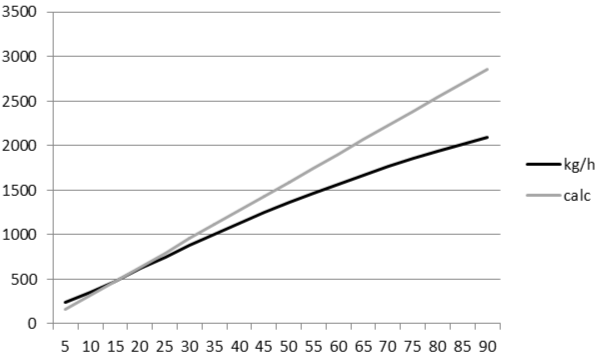

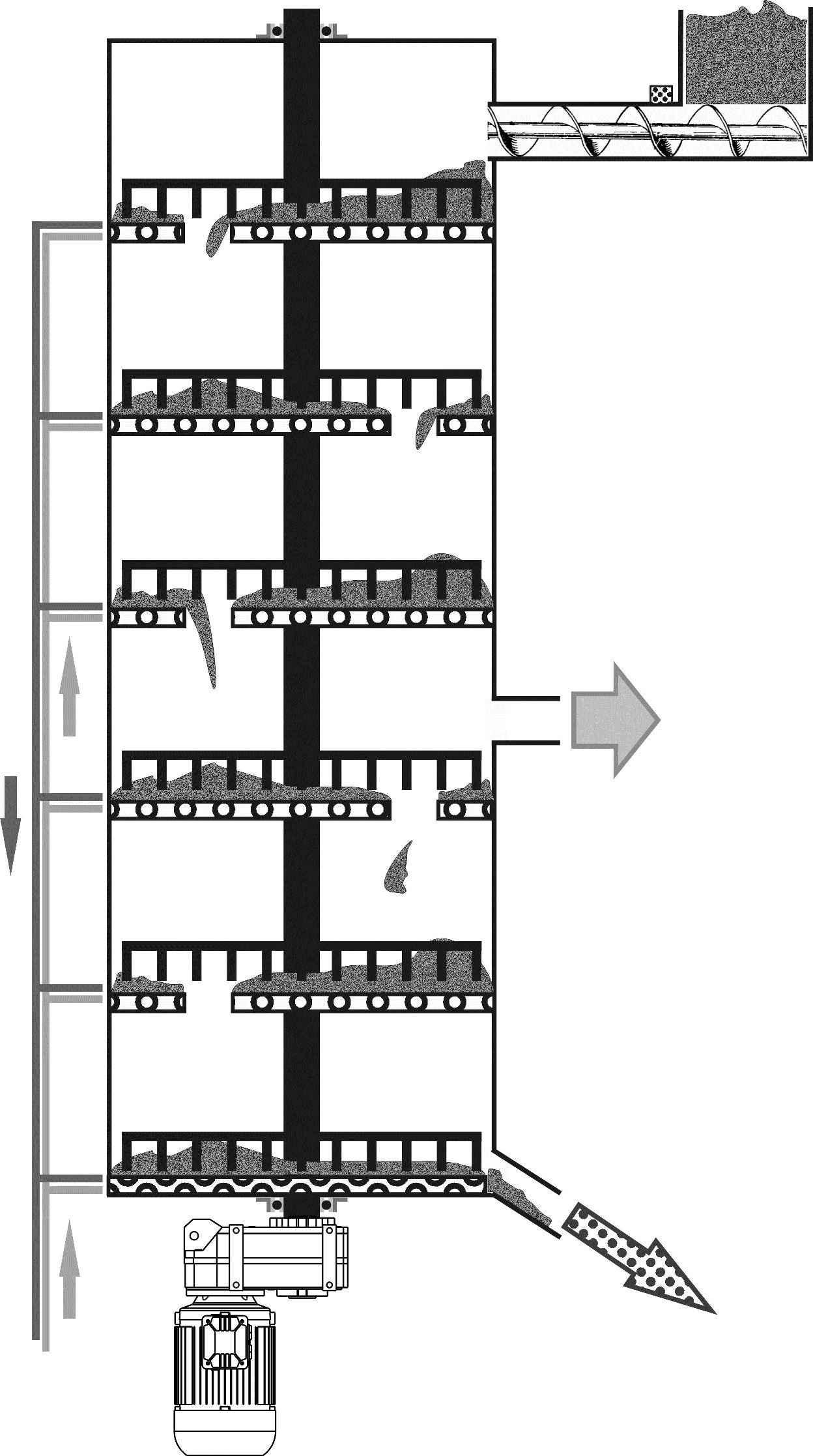

The unit typically consists of two to eight vessels arranged vertically one above the other. Each vessel is a container with a double-walled body, through which a heat carrier in the form of steam or oil is supplied. A rotor shaft runs centrally through the entire stack, equipped with various attachments near the bottom of each level for mixing the raw material and evenly discharging it to the lower vessel or for unloading. The material is fed from the top and sequentially passes through all the levels with active mixing, while direct contact with the continuously heated surface ensures efficient and controlled heat transfer. Each level is usually fitted with an automatic heat carrier dosing device to maintain an individually set temperature. For example, in heating sunflower seeds, it is crucial to limit the temperature to the upper limit to prevent thermal damage to the material at a relatively low moisture content of 6-12%. In contrast, for sawdust with an initial moisture content of 50-55%, much higher carrier temperatures are permissible. Therefore, when using the roaster as a dryer, the top vessel, which first encounters the wet material, receives the heat carrier at maximum temperature without the risk of charring. Furthermore, steam formed in the upper vessel has much better heat transfer properties in the cavities with the material and helps accelerate the initial heating of the material to 70-80°C (158-176°F), at which active evaporation of most of the water begins on subsequent levels.

Steam is usually withdrawn from the middle vessel as it freely moves within the roaster's body. Thus, the upper third is where active heating of the material occurs, the middle sees most of the moisture evaporate, and the lower levels achieve final drying. Temperature adjustment in these areas allows for the most gentle drying of the material with the highest capacity possible for the unit.

There are two notable drawbacks when using a roaster for biomass drying: issues with moving clumping material and working with heat carriers. Unlike grains, wood material tends to clump at the ends of the blades and in narrow passages between vessels. The relatively slow mixing and hanging of the material practically exclude the possibility of using heat generator flue gases as a thermal agent since local overheating inevitably leads to ignition. Uneven and episodic clump formation demands high strength from the rotor with stirrers and its power reserve, not adding stability to the work. Mixing a layer of fibrous material demands considerably more power consumption than tumbling the same mass in a rotating drum. Therefore, this design requires increasing shaft diameters and gear sizes, leading to inevitable increases in cost compared to classic solutions.

Working with superheated steam or oil as a heat carrier often not only complicates the commissioning of production due to additional permits and certifications but also raises the requirements for worker qualifications and workplace safety. Such a solution for producing fuel pellets, a production with relatively low margins, is justified if the enterprise already uses boilers with such heat carriers and is especially advantageous when utilizing waste or nearly free heat from power plants or geothermal sources.

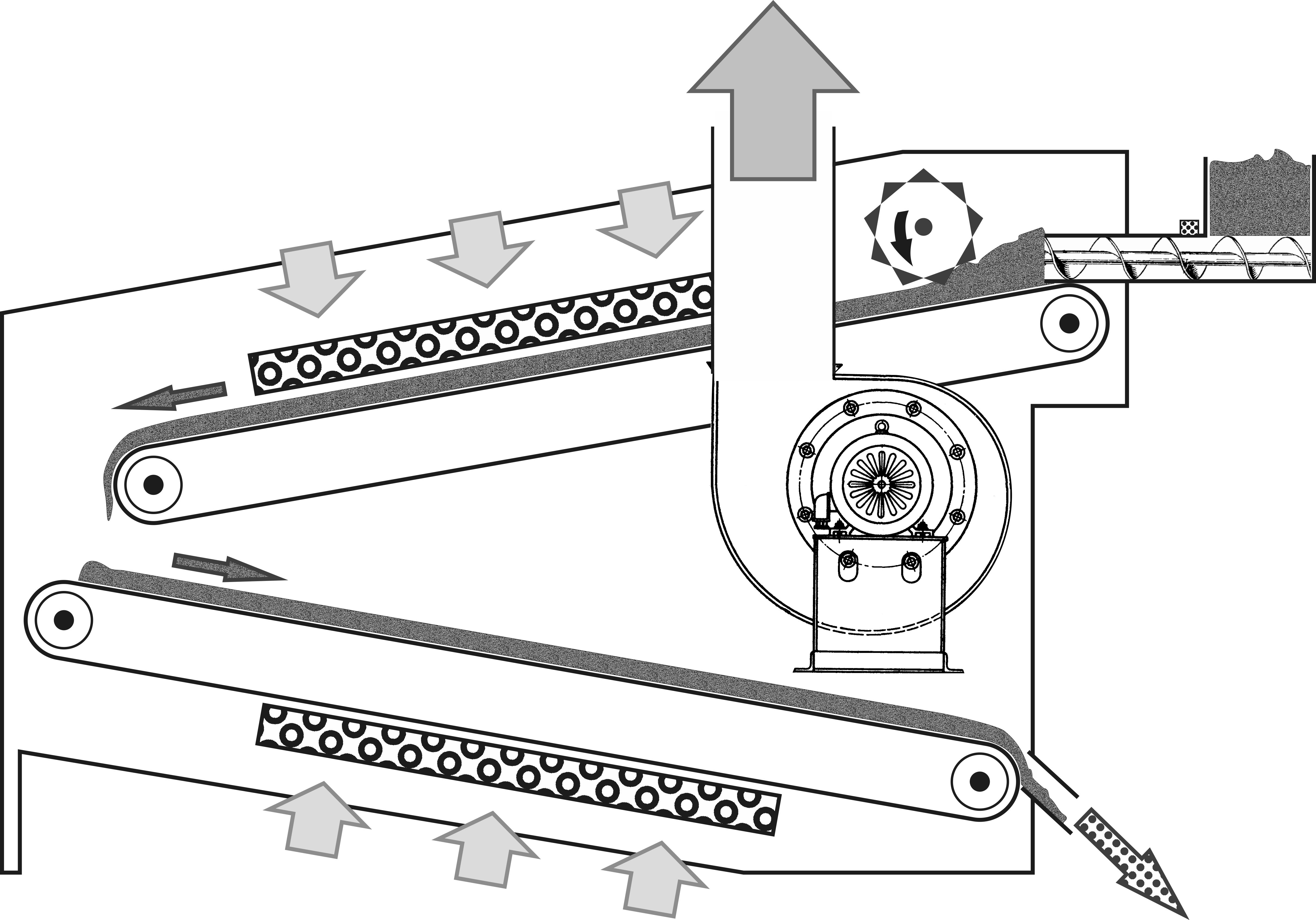

An undeniable advantage of the dryer with indirect heating is its fire safety. The fundamental inability for the raw material to overheat to its ignition temperature is a very important argument for an investor when deciding on financing a new production facility. Although in this regard, belt dryers have gained the most popularity.