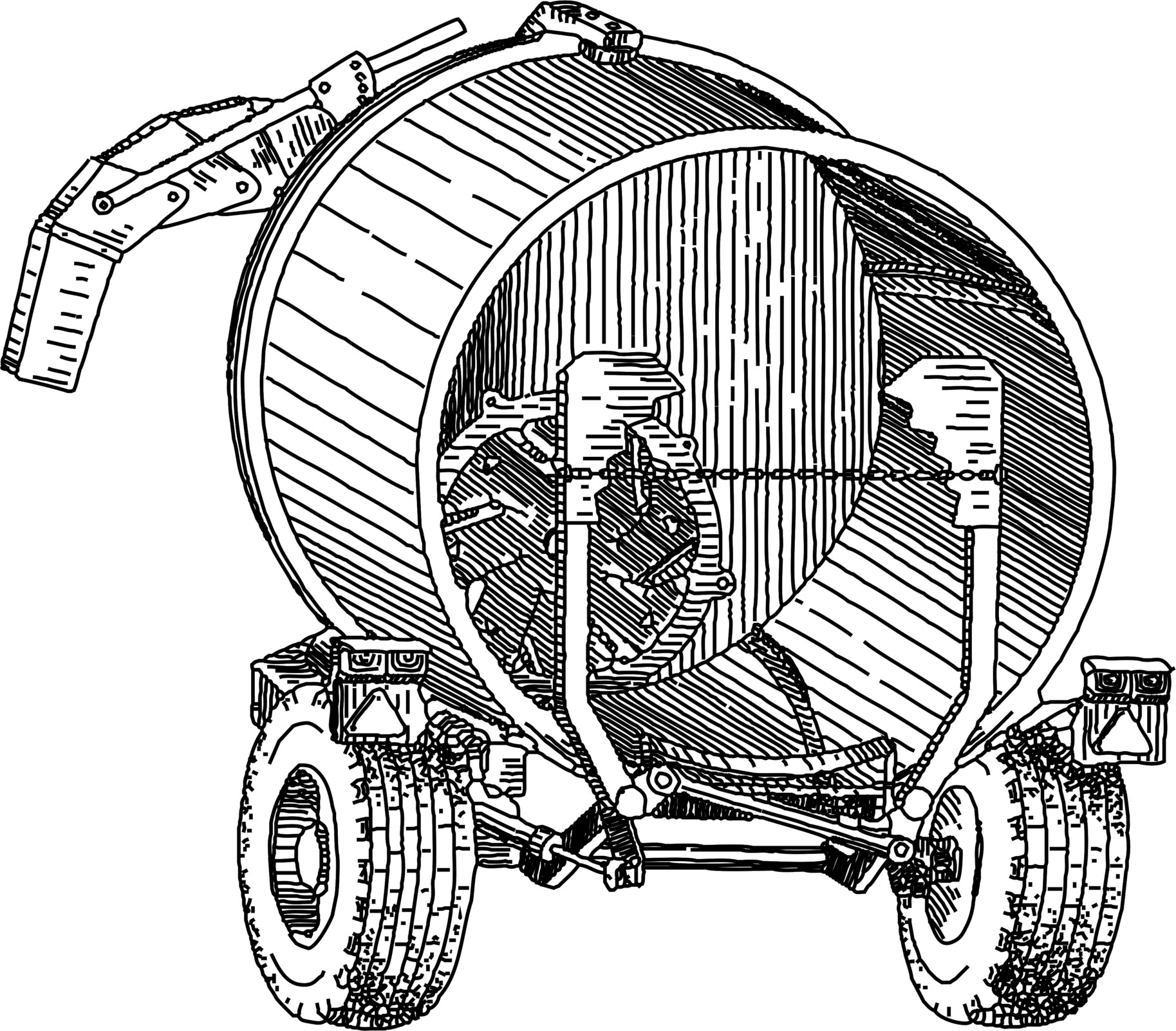

The IRR is a unit designed for shredding bales and rolls of straw or hay to produce "chaff" ranging from 5 to 50 mm (0.2 to 2 inches) in length. The most popular and low-maintenance designs are a combination of a hammer mill with a rotating drum without a bottom, with a diameter of 1 to 1.5 meters (3.3 to 5 feet). Inside the drum, there are 3-5 paddles that ensure the tumbling of the bales and their feeding onto the hammers (knives).

The IRR is a unit designed for shredding bales and rolls of straw or hay to produce "chaff" ranging from 5 to 50 mm (0.2 to 2 inches) in length. The most popular and low-maintenance designs are a combination of a hammer mill with a rotating drum without a bottom, with a diameter of 1 to 1.5 meters (3.3 to 5 feet). Inside the drum, there are 3-5 paddles that ensure the tumbling of the bales and their feeding onto the hammers (knives).

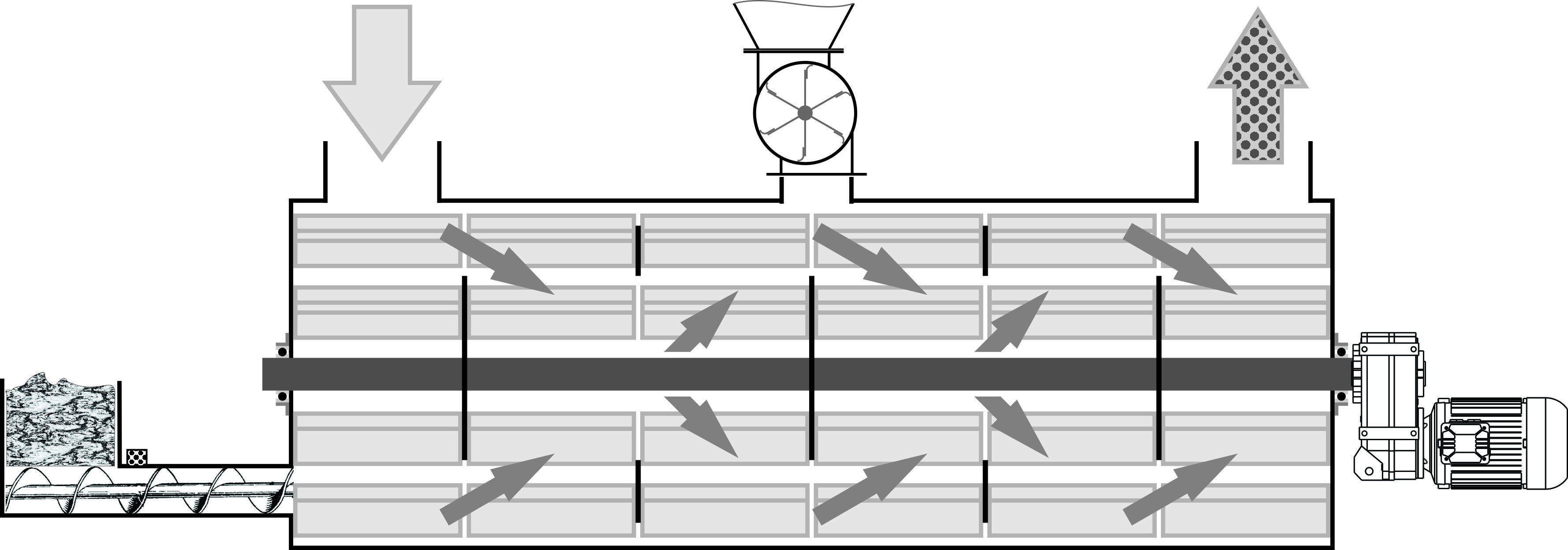

In models with a screen, the outgoing fraction is regulated by the size of the mesh, and the drum's rotation speed is adjusted for optimal load on the rotor drive. Screen-equipped shredders are more sensitive to the moisture content of the raw material, which should not exceed 15%.

In shredders without a screen, the fraction can be adjusted by the drum speed, the number, and thickness of the hammers, although the setting is very coarse with a wide range of chaff sizes produced. In such shredders, the initial moisture content can be up to 40% if the design does not include beaters that facilitate sticking.

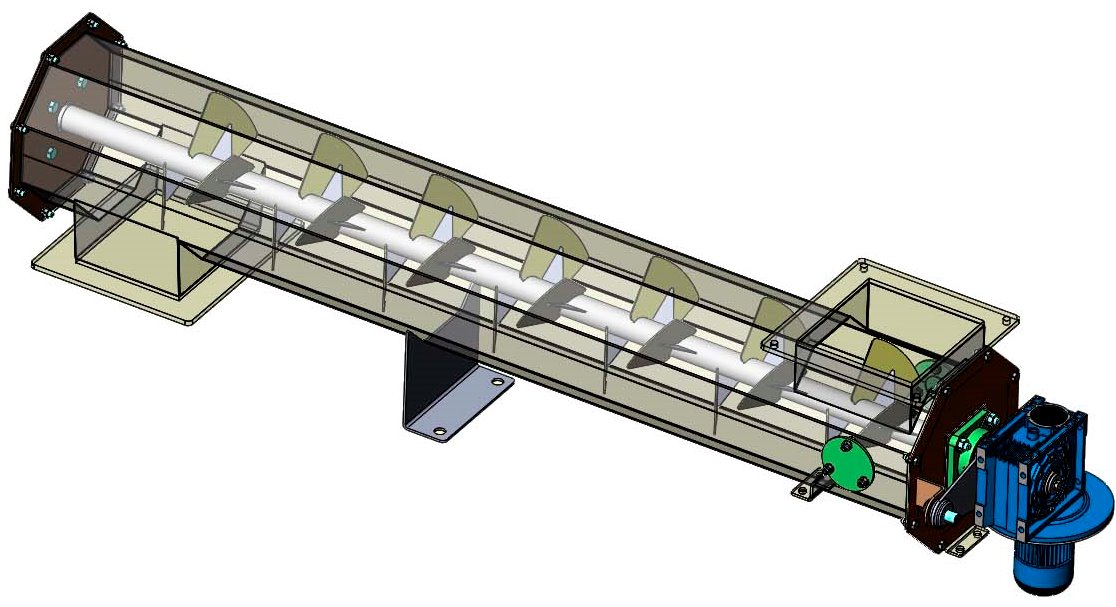

There are models with vertical and horizontal hoppers of various diameters, with feeding conveyors or loading devices, powered either by the tractor's power take-off (PTO) shaft or by an electric drive. The configuration for a specific pellet production is selected individually, depending on the size of the rolls and bales, as well as their density, moisture content, required throughput, and the fraction at the output. These parameters need to be coordinated with raw material suppliers to avoid having to completely rebuild the reception and primary processing area just a few months after production starts.

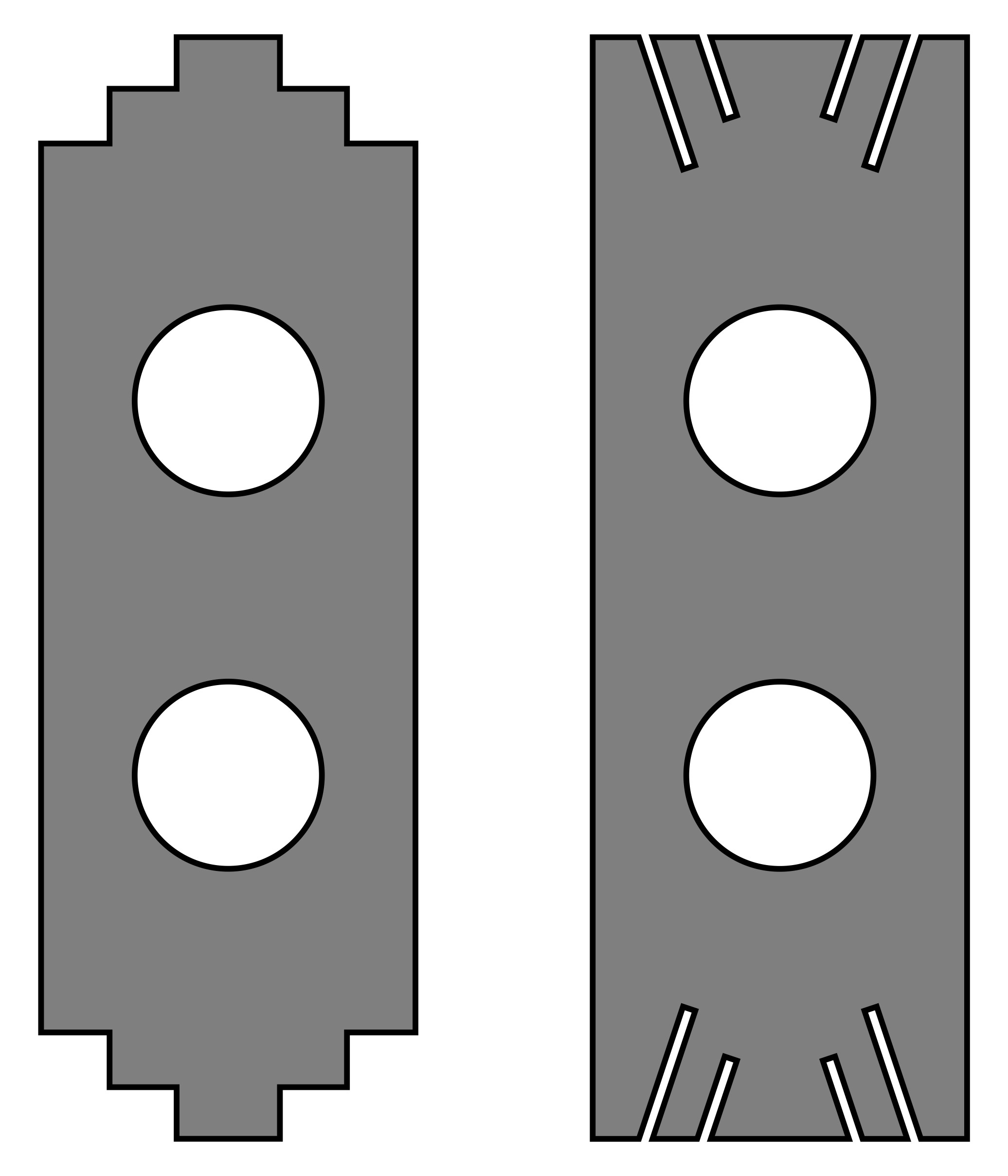

A very useful feature can be the inclusion of a special device that cuts and removes strings from the surface of the bales and rolls. This is usually done manually, which is quite hazardous. Forgotten strings can wind up on the rotor, blocking the hammers and causing destructive imbalance.