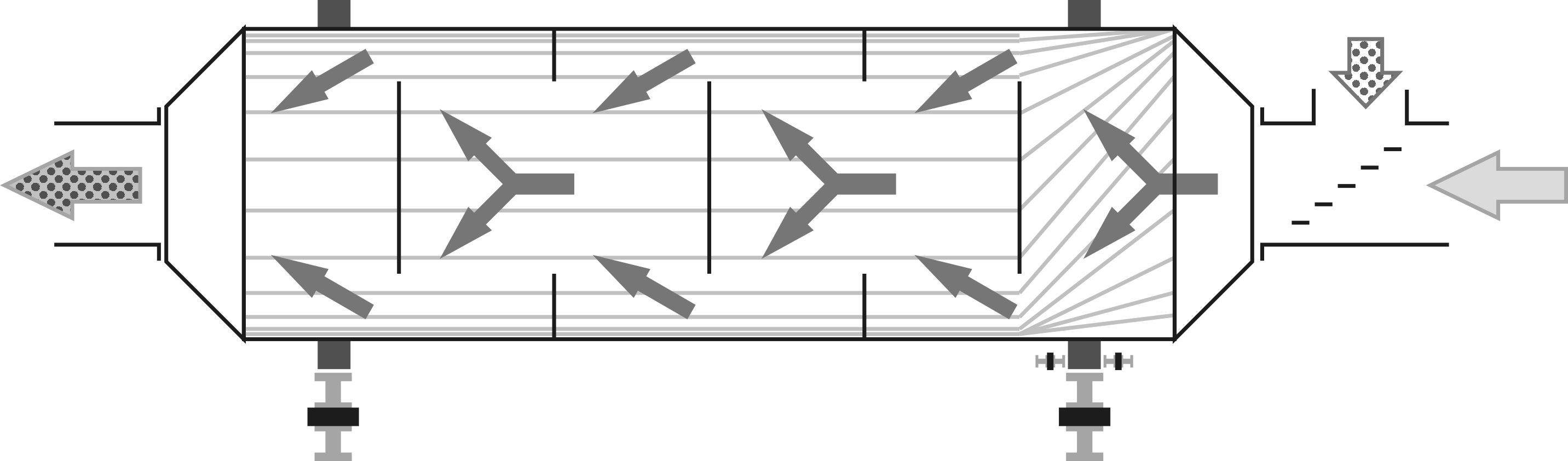

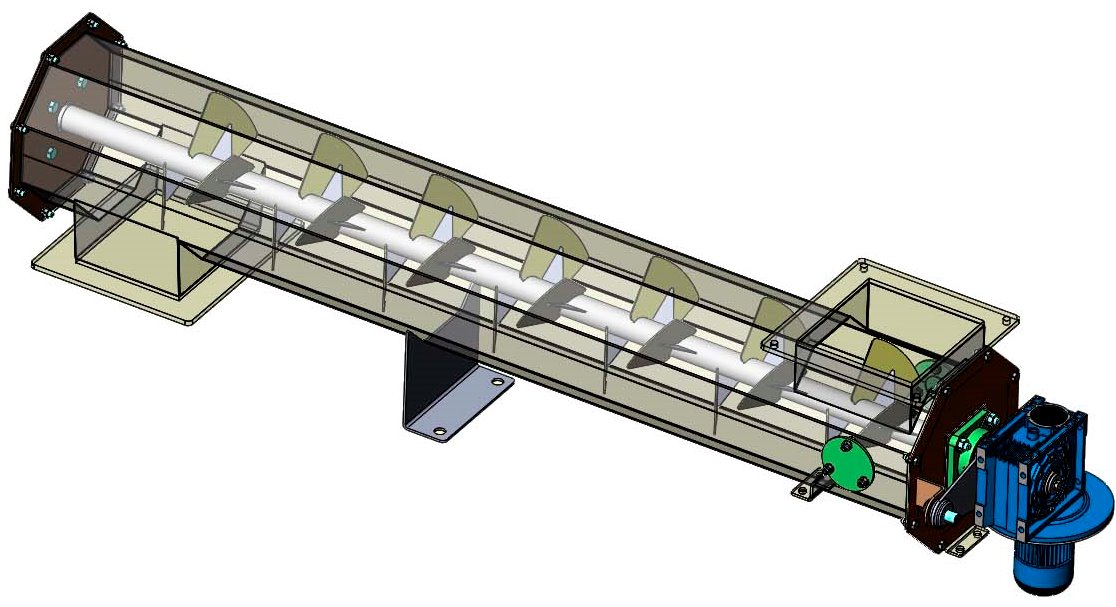

There exists a variation called the rotary-vortex dryer, where instead of buckets, scrapers on long brackets are installed, providing mixing of actively blown material. Hot air is supplied tangentially through a slot along the entire length of the side, helping accelerate the rotating mass of air inside the oval body, reflecting the name "vortex" dryer. The blades merely initiate the movement of the material, which, after initial drying, starts floating freely in the streams of hot air. This process mechanics facilitates further drying, especially in the challenging range from 16 to 10%, when "free" water is almost gone, and breaking the bond with hygroscopic substances is necessary for evaporation. This design is far more suitable for drying shavings, i.e., removing a small amount of moisture with a thermal agent at a temperature of 120-150°C (248-302°F). The manufacturer offers a wood-fired heat generator with a built-in heat exchanger; thus, clean atmospheric air is used as the thermal agent, which preserves the light color of the material and results in a photogenic pellet for cat litter filler. For drying sawdust with natural moisture, the efficiency is quite low due to large heat losses, as the difference between the inlet and outlet temperatures is only 40-50°C (104-122°F), requiring 2-3 times more thermal agent than in drum or rotary-bucket variants.

There exists a variation called the rotary-vortex dryer, where instead of buckets, scrapers on long brackets are installed, providing mixing of actively blown material. Hot air is supplied tangentially through a slot along the entire length of the side, helping accelerate the rotating mass of air inside the oval body, reflecting the name "vortex" dryer. The blades merely initiate the movement of the material, which, after initial drying, starts floating freely in the streams of hot air. This process mechanics facilitates further drying, especially in the challenging range from 16 to 10%, when "free" water is almost gone, and breaking the bond with hygroscopic substances is necessary for evaporation. This design is far more suitable for drying shavings, i.e., removing a small amount of moisture with a thermal agent at a temperature of 120-150°C (248-302°F). The manufacturer offers a wood-fired heat generator with a built-in heat exchanger; thus, clean atmospheric air is used as the thermal agent, which preserves the light color of the material and results in a photogenic pellet for cat litter filler. For drying sawdust with natural moisture, the efficiency is quite low due to large heat losses, as the difference between the inlet and outlet temperatures is only 40-50°C (104-122°F), requiring 2-3 times more thermal agent than in drum or rotary-bucket variants.

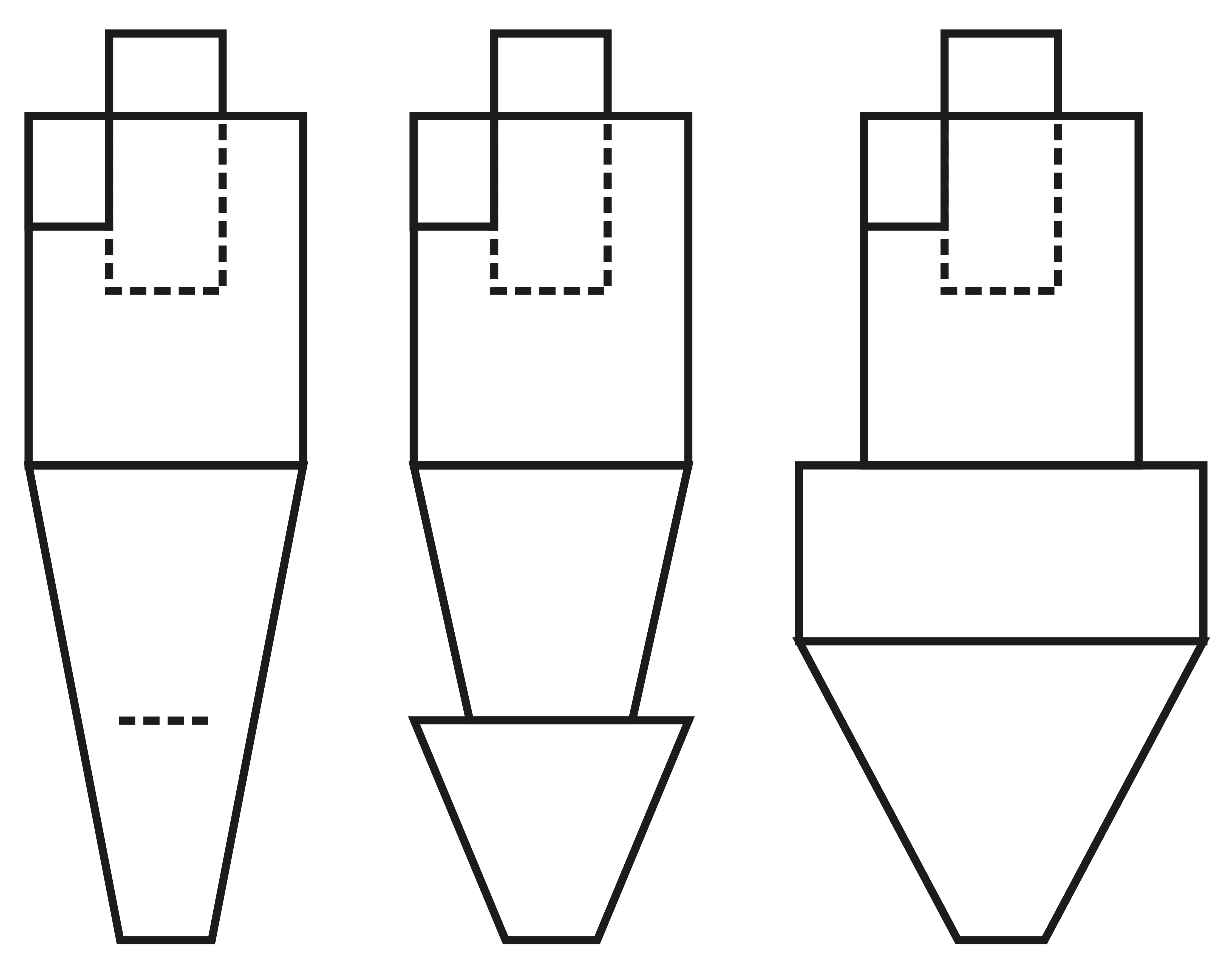

Interestingly, the carrying capacity of the blades in a vortex dryer with a rotor is extremely low, and despite the enormous airflow through the dryer, a combined method must be used for material discharge: the main part is unloaded into a conveyor from a window at the end of the dryer, while the lightest particles are carried into a cyclone. Capturing dust in such volumes and with such fine fractions is a separate costly task. The setup employs a cyclone and smoke exhaust fan designed for 18,000 cubic meters per hour (636,000 cubic feet per hour). A single cyclone, for increased capture efficiency, should not just be an option but must be replaced with a multicyclone. The specifics of capital expenses and energy consumption remain beyond the description of the device.

Interestingly, the carrying capacity of the blades in a vortex dryer with a rotor is extremely low, and despite the enormous airflow through the dryer, a combined method must be used for material discharge: the main part is unloaded into a conveyor from a window at the end of the dryer, while the lightest particles are carried into a cyclone. Capturing dust in such volumes and with such fine fractions is a separate costly task. The setup employs a cyclone and smoke exhaust fan designed for 18,000 cubic meters per hour (636,000 cubic feet per hour). A single cyclone, for increased capture efficiency, should not just be an option but must be replaced with a multicyclone. The specifics of capital expenses and energy consumption remain beyond the description of the device.