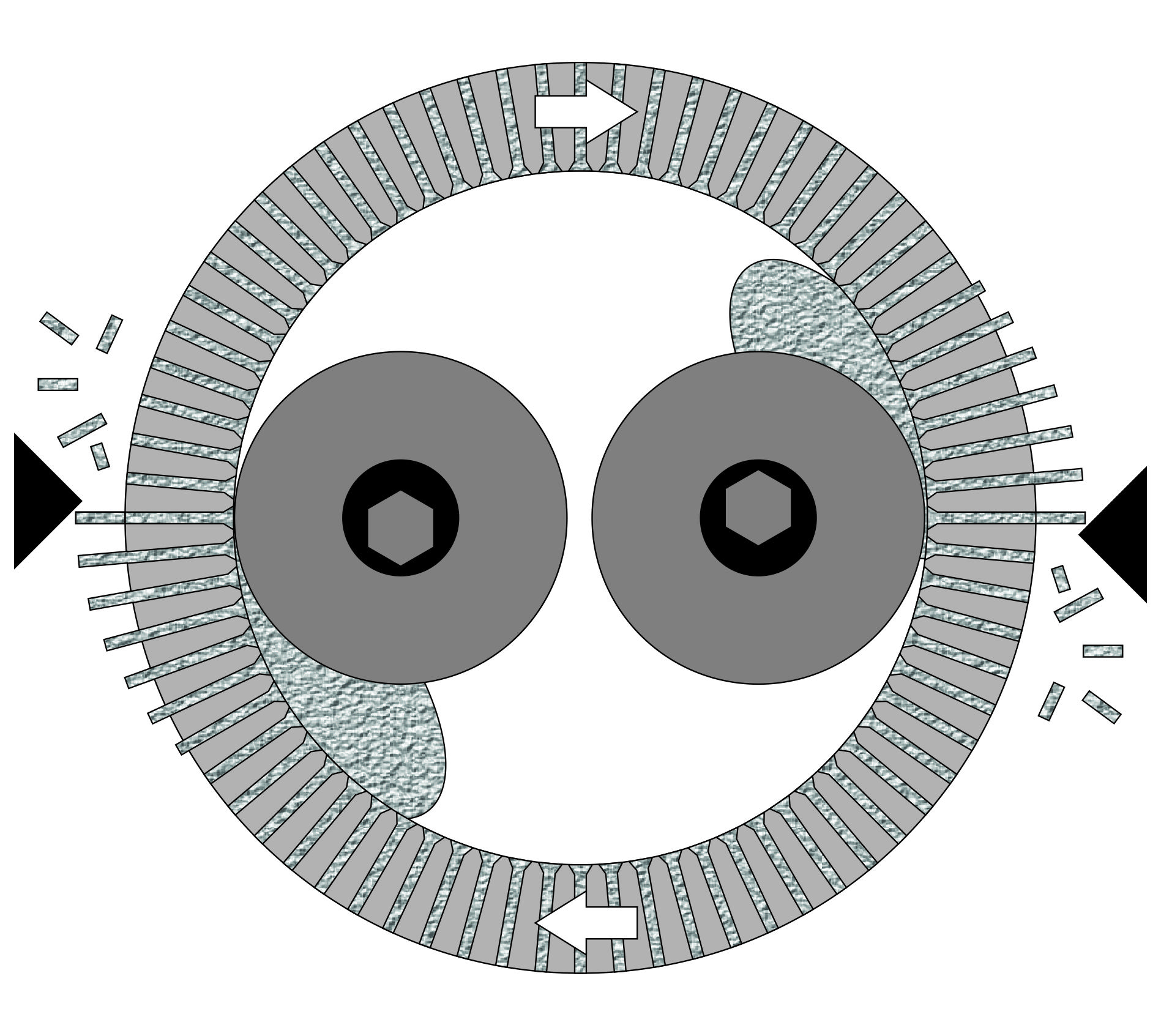

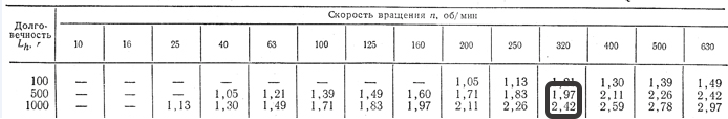

The most significant changes in the structure of the raw material occur on the surface of the ring die track. Periodic rolling with the toothed surface of the roller rim pushes more particles into the layer, compressing and heating them. Fresh and still harder portions settle onto the softened heated layer, which is sliced under pressure by the edges of the die holes, known as countersinks, and pressed into the die openings. Thus, the roller rim primarily interacts with fresh material, while the die contacts the mass already prepared for forming. This explains the relatively higher wear on the roller shells compared to the die, even though their hardness of 62-64 HRC is noticeably higher than the die's hardness of 52-56 HRC. The yield strength of most types of wood at room temperature with force applied along the fibers is about 40 MPa (400 kg/cm²), and calculations of load on the mechanisms of the pellet mill should be based on this figure. Particles can be arranged in any direction in space, but within the pellet, they must be almost entirely deformed and compacted. The width of the raw material spot where interaction occurs under maximum load is determined by the diameter of the die and rollers. The simplest way to measure is to stop the pellet mill during nominal operation and clean out the pressing unit. Compression marks from compressed and baked raw material will remain on the die. For a die with an inner diameter of 480 mm (19 inches), the compression zone with maximum load is typically 30-50 mm (1-2 inches). Therefore, the load on each roller with a track width of 78 mm (3 inches) will be 9-15 tons. For required durability of at least 1000 hours, a reserve 2.5 to 3 times greater than the nominal load value on the roller bearing is necessary. Only one bearing is considered in the calculation because the non-uniformity of the material and the behavior of the pressed layer produce chaotic impact loads with constantly changing direction. For example, the far part of the track may receive insufficient material, causing it to overheat, dry out, and take on a larger share of the load directly opposite one of the bearings. For the described conditions, you can compare the theoretical lifespan of 7614 and 7616 bearings used in OGM-1.5 and GRACH-480 pellet mills, respectively. In these pellet mills, the dies are identical, while the roller diameter is 190 mm (7 inches) and 230 mm (9 inches), respectively. Bearing ratings in the rollers differ by about 30-35%, but according to the lifespan table, the difference in service life is 500 and 1000 hours, respectively, which is essentially a two-fold difference. This explains the developers' inclination to use the largest possible roller diameter that occupies all the space inside the die. Additionally, extra load capacity allows temporary overloads to be handled without causing scoring and chipping on the bearing’s rolling elements.

To avoid radically changing the design of the pellet mill and have the ability to process materials of varying hardness, dies with different track widths are used. For the GRACH-480, "feed-type" dies have a track width of 120 mm (5 inches), while "wood-type" dies have a width of 78 mm (3 inches), with all other geometric dimensions being practically identical. In principle, it is possible to pelletize any raw material on any mill by adjusting only the track width to ensure acceptable bearing life. It is important to consider that reducing the track width decreases productivity and significantly increases the share of expenses in the cost of roller rims and dies, which are considered consumables.

To avoid radically changing the design of the pellet mill and have the ability to process materials of varying hardness, dies with different track widths are used. For the GRACH-480, "feed-type" dies have a track width of 120 mm (5 inches), while "wood-type" dies have a width of 78 mm (3 inches), with all other geometric dimensions being practically identical. In principle, it is possible to pelletize any raw material on any mill by adjusting only the track width to ensure acceptable bearing life. It is important to consider that reducing the track width decreases productivity and significantly increases the share of expenses in the cost of roller rims and dies, which are considered consumables.

It is surprising that the measured pressure of the raw material against the die wall is only 5-7% of the applied pressure when it is pushed into the hole. The ratio of the friction force against the walls to the pressing force is determined by the internal working area of the die, which is 15-25 times larger than the cross-section of the die. Thus, the determining factor for compressing force is the established coefficient of friction of the raw material against the steel of the die. This coefficient is nonlinear and behaves differently based on the temperature, humidity, and abrasiveness of the raw material. The die exhibits the greatest resistance when the raw material has a moisture content of 10% at an operating temperature of 70-90°C (158-194°F). Brief changes to 5% or 15% moisture content lead to reduced load. If, however, the die is still cold or has been cooled to 20-30°C (68-86°F) by a brief excess water supply, then feeding sawdust with 5% moisture content increases the load by 30-50%. This almost always results in jamming of the material and an emergency shutdown. These moisture percentages refer to the material already inside the die, not what is being fed into the pressing unit, and are provided for process understanding. The most common mistake of an inexperienced operator is random, pulsed water additions, leading to an emergency shutdown, especially when overdried material is fed into a cooled die.