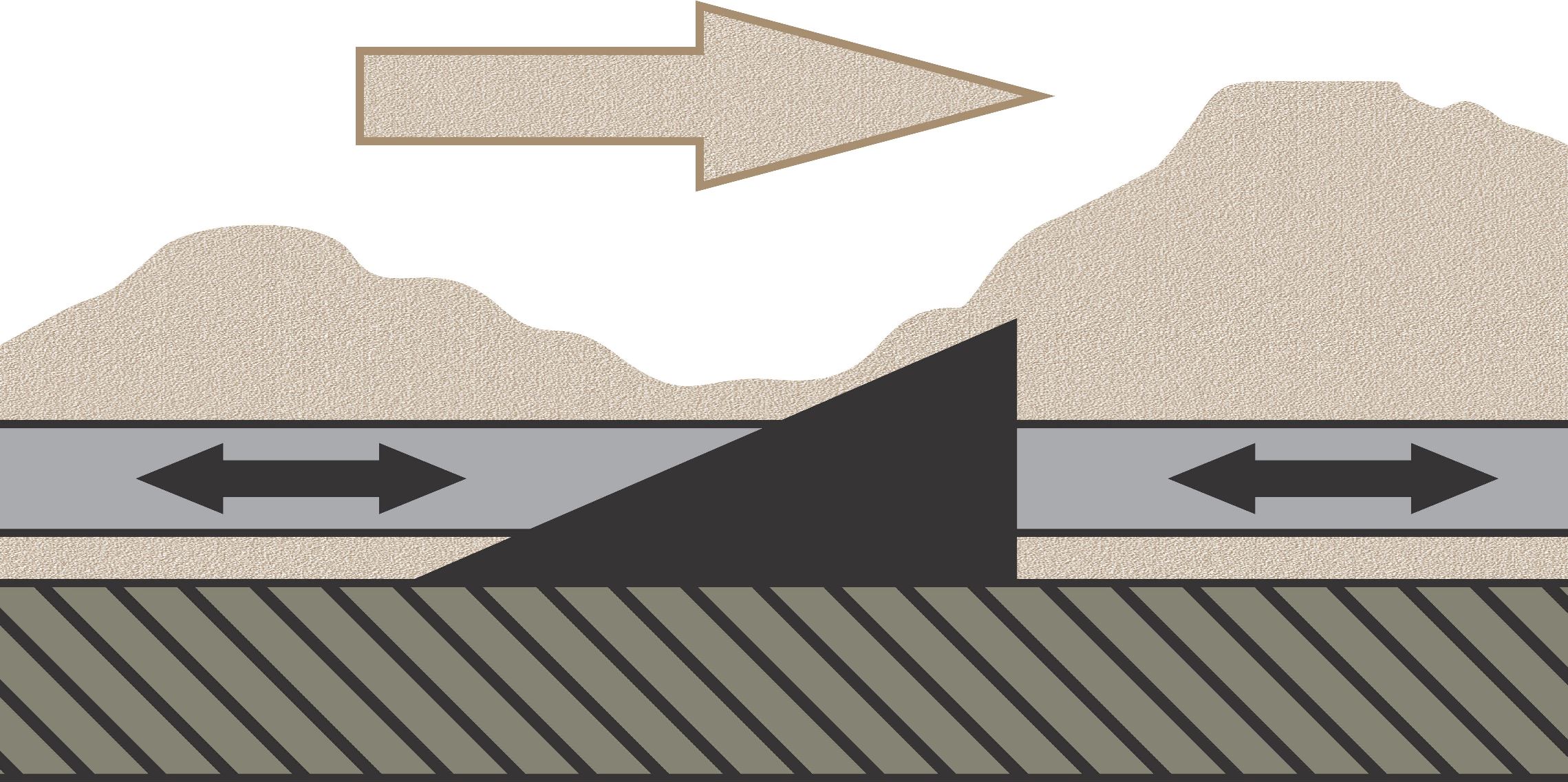

Fraction separation in milling, based on different settling speeds depending on particle size, is usually used in devices known as classifiers. These classifiers can be standalone units or integrated into mills and mills for fine grinding. The operation of a classifier can be thought of as a competition between two dust fans with different wheel diameters. The larger diameter fan creates greater vacuum, forcing air towards the smaller fan. The smaller wheel, accelerating the mixture of large and small particles along with the air, ensures centrifugal separation of the larger fraction, while the dust manages to pass through with the air. Thus, large particles either remain in the grinding chamber or return to it through special tubes. For greater flexibility in adjusting the classifier, the impellers are driven by different motors controlled by frequency converters. This allows for the regulation of both the total airflow and the "separation force" of particles, meaning the settings for the maximum particle sizes removed from the toroidal cloud can be adjusted.

Fraction separation in milling, based on different settling speeds depending on particle size, is usually used in devices known as classifiers. These classifiers can be standalone units or integrated into mills and mills for fine grinding. The operation of a classifier can be thought of as a competition between two dust fans with different wheel diameters. The larger diameter fan creates greater vacuum, forcing air towards the smaller fan. The smaller wheel, accelerating the mixture of large and small particles along with the air, ensures centrifugal separation of the larger fraction, while the dust manages to pass through with the air. Thus, large particles either remain in the grinding chamber or return to it through special tubes. For greater flexibility in adjusting the classifier, the impellers are driven by different motors controlled by frequency converters. This allows for the regulation of both the total airflow and the "separation force" of particles, meaning the settings for the maximum particle sizes removed from the toroidal cloud can be adjusted.

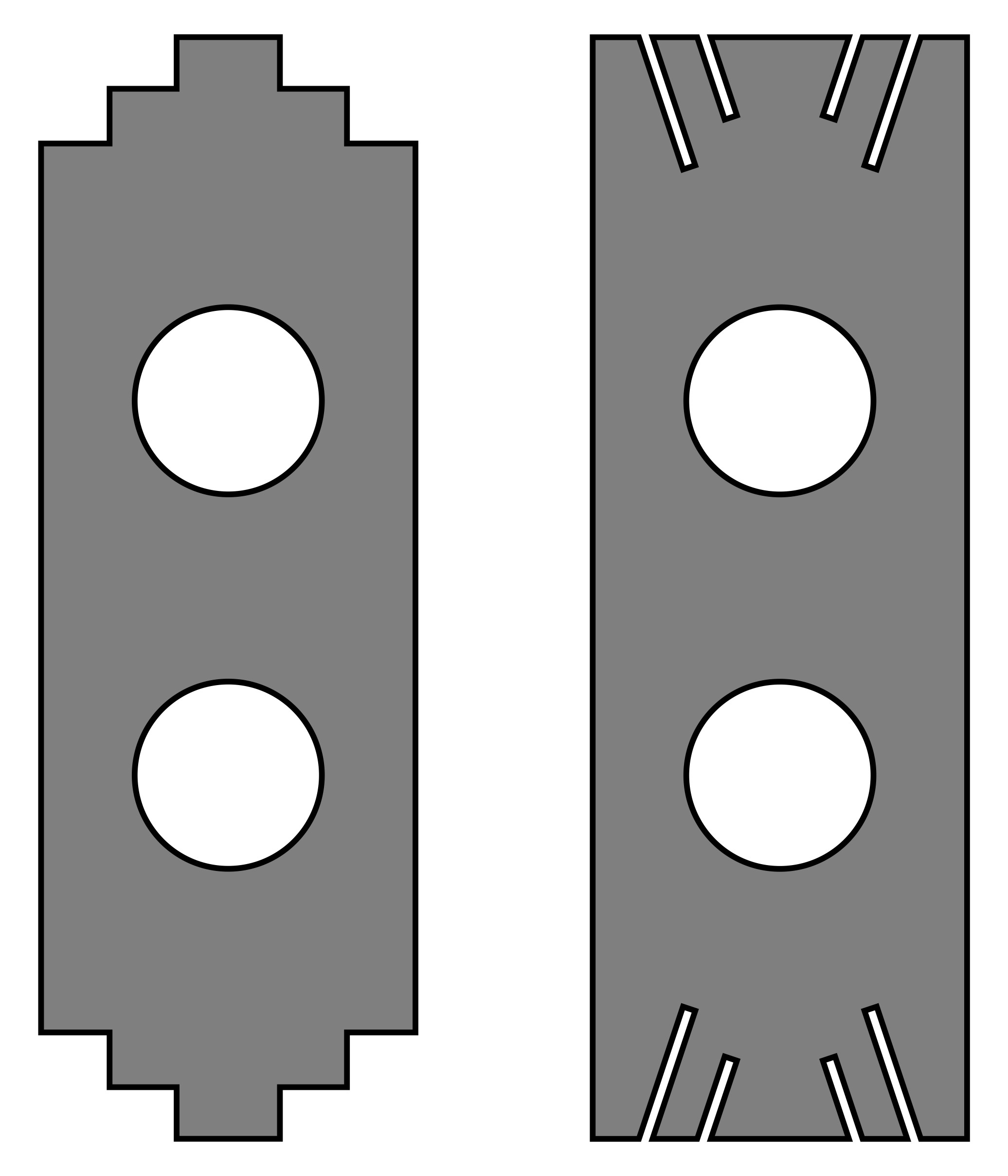

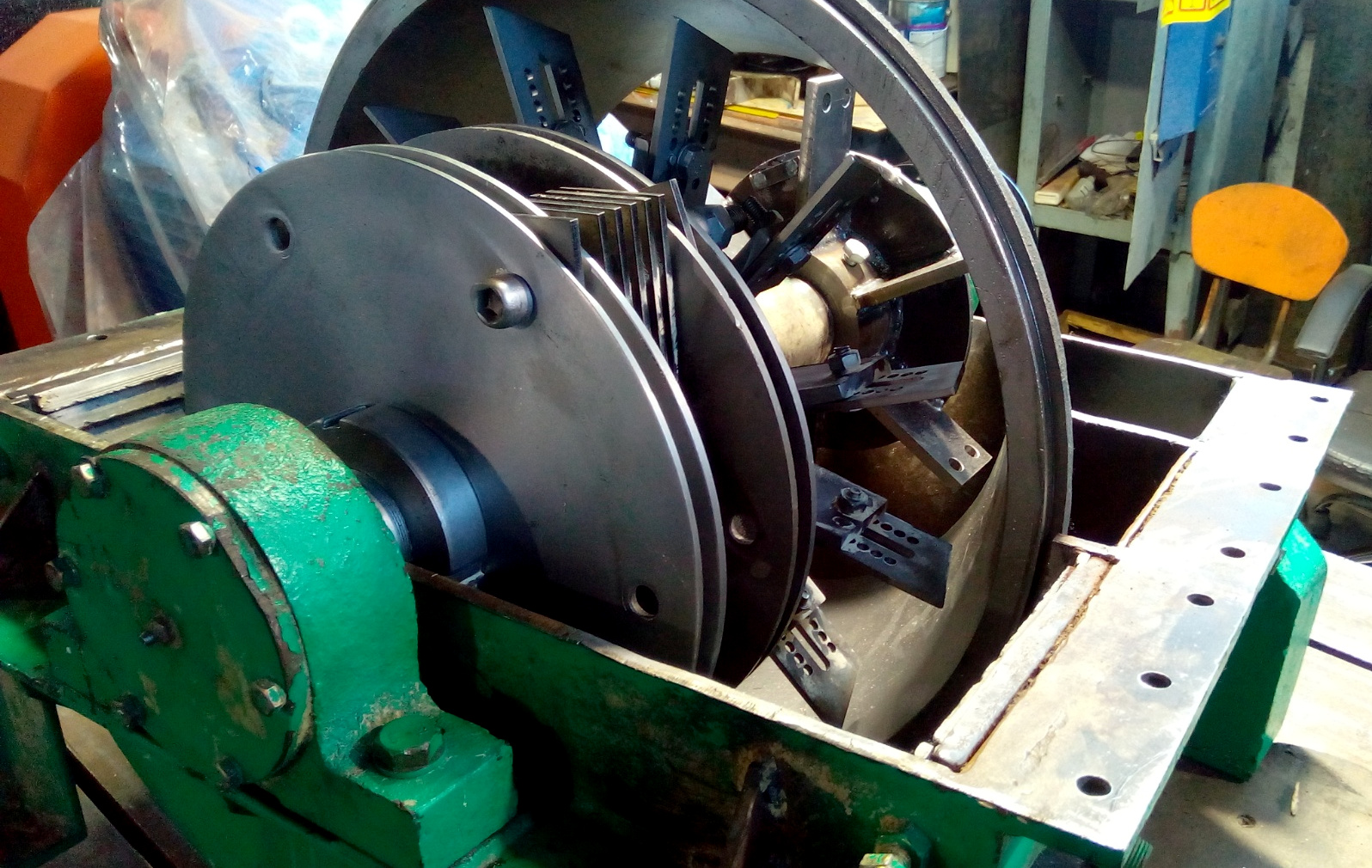

The use of this classification principle allows the design of mills without the need for screens. Installing classifier blades and the main product fan blades directly on the mill rotor shaft greatly simplifies the construction. To adjust the fraction size, the length of the blades is changed by relocating them to predetermined attachment points. The counterpart of the classifier for more effective separation is made conical in shape, cast from wear-resistant iron. Meanwhile, a simple disc-shaped partition between the fan and the classifier works just as efficiently and is much cheaper.

The use of this classification principle allows the design of mills without the need for screens. Installing classifier blades and the main product fan blades directly on the mill rotor shaft greatly simplifies the construction. To adjust the fraction size, the length of the blades is changed by relocating them to predetermined attachment points. The counterpart of the classifier for more effective separation is made conical in shape, cast from wear-resistant iron. Meanwhile, a simple disc-shaped partition between the fan and the classifier works just as efficiently and is much cheaper.

The photo shows that the grinding chamber is lined with ribbed cast-iron inserts. This is a fairly reliable and durable solution. However, an octagonal or hexagonal body lined with 5-10 mm (0.2-0.4 inches) hardened 65G steel plates works just as well. It has been proven that the biggest contribution to the crushing process comes from the swirling and mutual abrasion of particles, rather than directly from hammer impact. Therefore, the primary task of the liners is to hold the raw material between encounters with the hammers. A secondary task is to protect the casing from wear, which is ensured by their scheduled replacement. Plate protection is easy to fabricate with hand tools, which can be important for facilities located far from major cities and in areas with challenging transportation access.

The photo shows that the grinding chamber is lined with ribbed cast-iron inserts. This is a fairly reliable and durable solution. However, an octagonal or hexagonal body lined with 5-10 mm (0.2-0.4 inches) hardened 65G steel plates works just as well. It has been proven that the biggest contribution to the crushing process comes from the swirling and mutual abrasion of particles, rather than directly from hammer impact. Therefore, the primary task of the liners is to hold the raw material between encounters with the hammers. A secondary task is to protect the casing from wear, which is ensured by their scheduled replacement. Plate protection is easy to fabricate with hand tools, which can be important for facilities located far from major cities and in areas with challenging transportation access.

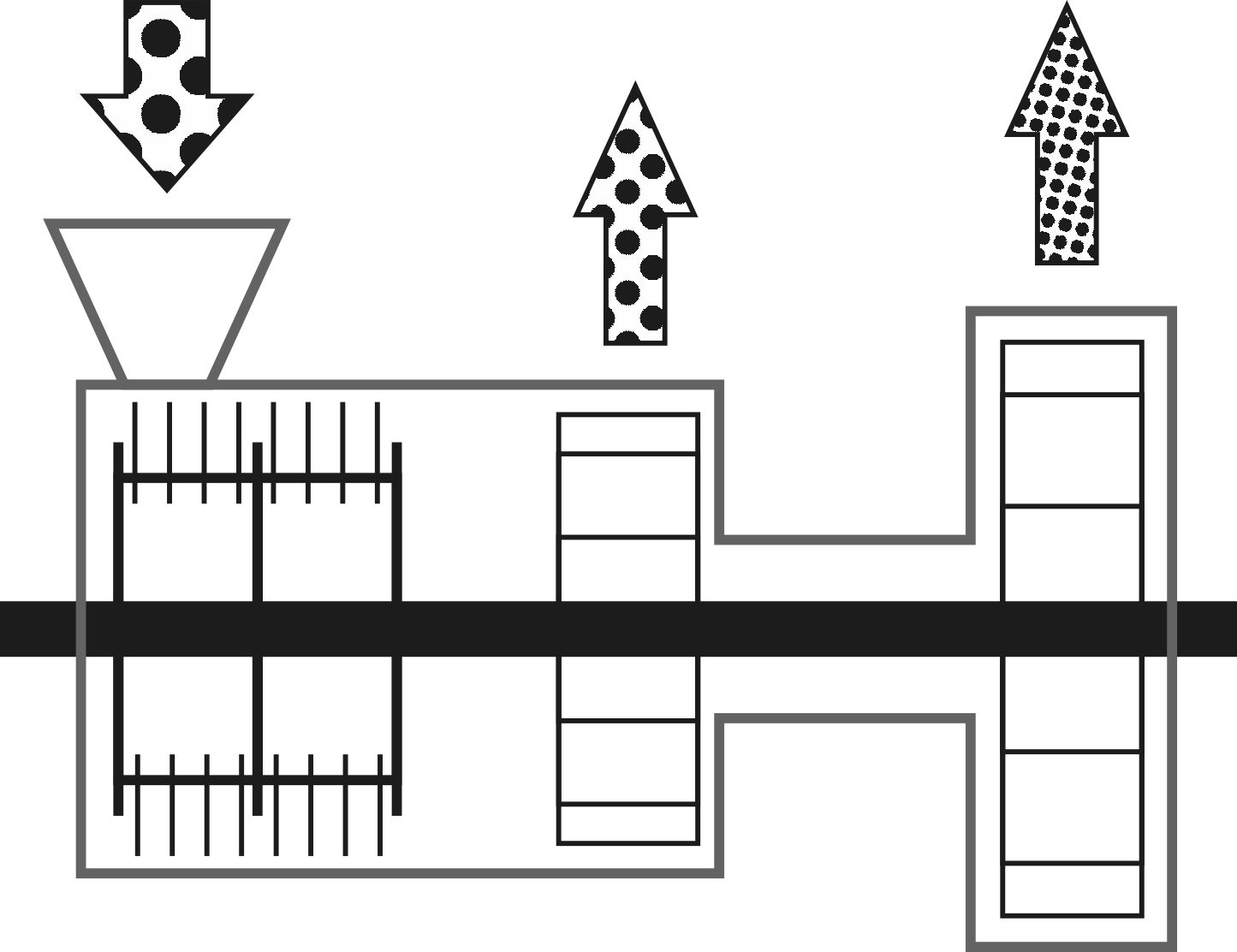

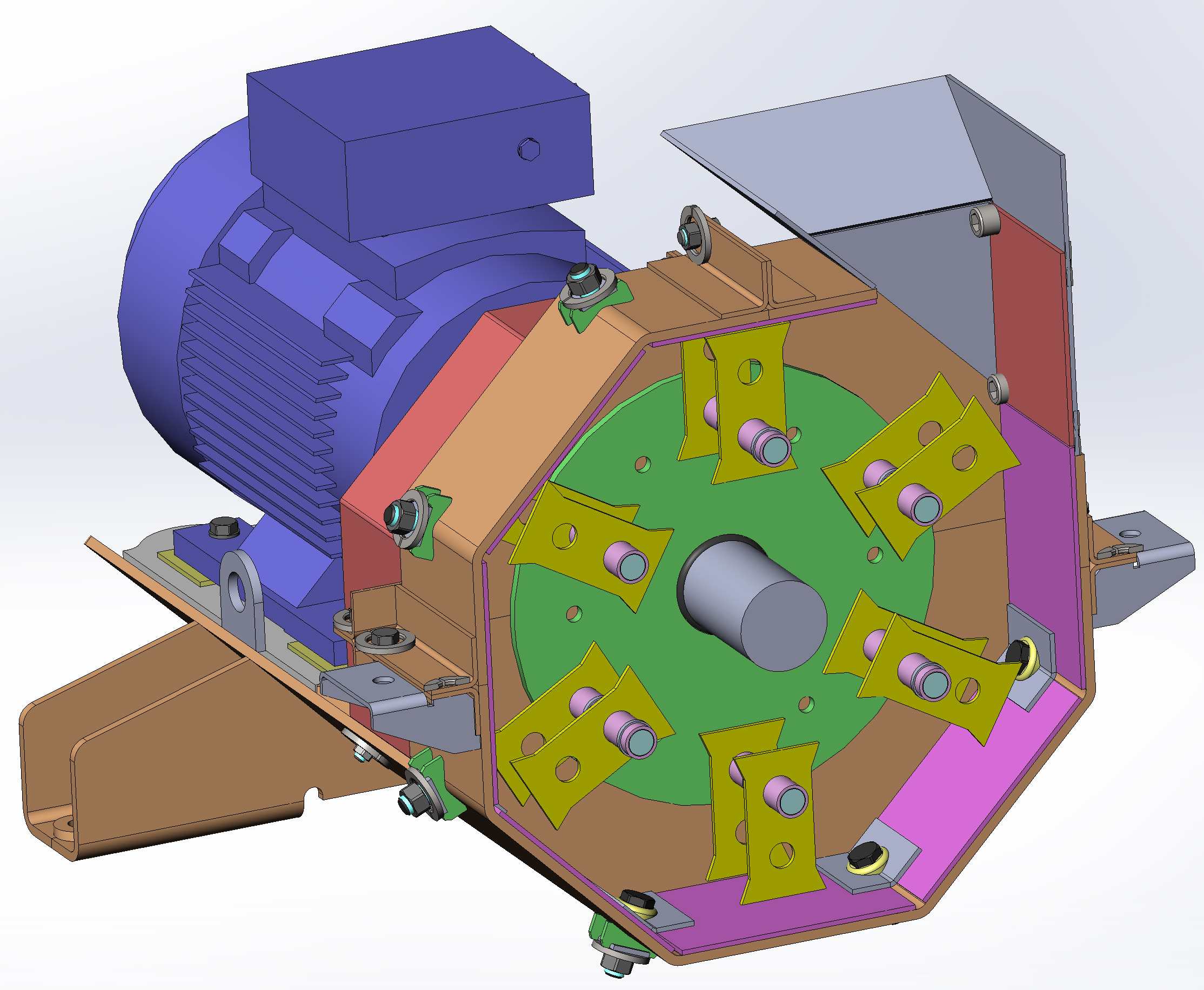

An example of a screenless mill with an octagonal body and a single shaft rotor with hammers, classifier blades, and a fan is the DMBK-75 hammer mill. The absence of a screen allows the processing of wood chips with a main fraction of up to 50 mm (2 inches), and the occurrence of individual sticks up to 200 mm (8 inches) long causes no damage. Adjusting the classifier provides a maximum fraction size of 3-5 mm (0.1-0.2 inches) at an output of 1-2 tons per hour, and when set for a minimum fraction, wood flour of 100-200 microns (Mesh 150 - Mesh 70) can be achieved in a single pass from relatively large chips, with an output of up to 100 kg/hour (220 pounds/hour).

An example of a screenless mill with an octagonal body and a single shaft rotor with hammers, classifier blades, and a fan is the DMBK-75 hammer mill. The absence of a screen allows the processing of wood chips with a main fraction of up to 50 mm (2 inches), and the occurrence of individual sticks up to 200 mm (8 inches) long causes no damage. Adjusting the classifier provides a maximum fraction size of 3-5 mm (0.1-0.2 inches) at an output of 1-2 tons per hour, and when set for a minimum fraction, wood flour of 100-200 microns (Mesh 150 - Mesh 70) can be achieved in a single pass from relatively large chips, with an output of up to 100 kg/hour (220 pounds/hour).

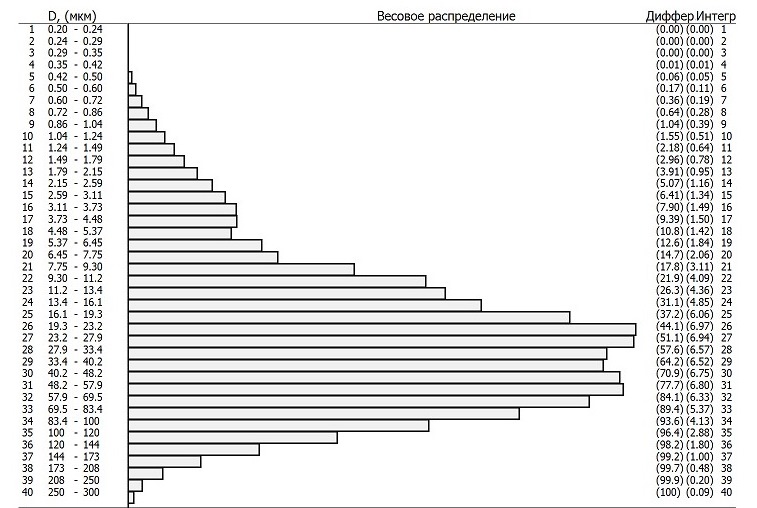

If you look at the weight distribution of the product by detected particle sizes, the M120 fraction (120 μm or Mesh 120) makes up 97% of the total mass. Adjusting to a fraction size of 200-400 microns (Mesh 70 - Mesh 40) with separation using a M200 (Mesh 70) grade sieve allows the mill to achieve a throughput of 200-250 kg per hour (440-550 pounds per hour) with energy consumption of 60-70 kW*h. This is an excellent result even for units from well-known global brands. Grinding increases the total surface area of raw material particles, and as the size decreases, the particle surface becomes rougher. Given this, the relationship between fraction size and performance is quadratic. This means that halving the fraction size requires approximately four times the drive power to maintain throughput.

If you look at the weight distribution of the product by detected particle sizes, the M120 fraction (120 μm or Mesh 120) makes up 97% of the total mass. Adjusting to a fraction size of 200-400 microns (Mesh 70 - Mesh 40) with separation using a M200 (Mesh 70) grade sieve allows the mill to achieve a throughput of 200-250 kg per hour (440-550 pounds per hour) with energy consumption of 60-70 kW*h. This is an excellent result even for units from well-known global brands. Grinding increases the total surface area of raw material particles, and as the size decreases, the particle surface becomes rougher. Given this, the relationship between fraction size and performance is quadratic. This means that halving the fraction size requires approximately four times the drive power to maintain throughput.

Although the grinding process with hammer mills and mills may appear simple, significant factors affect both equipment operability and safety:

- It is essential to check the airflow through the mill and calculate the total heat capacity of the air and raw materials being processed. Even in open systems, with sufficiently fine grinding, the air temperature can rise to 70-80°C (150-180°F) due to intense impact on a small volume of material. In the case of filter clogging or improper flow regulation with dampers, temperatures can quickly exceed 200°C (392°F), leading to fires and explosions. For safety, a temperature sensor before filters is mandatory with automatic equipment shutdown in case of overheating.

- Temperature sensors on mill bearings are highly recommended because their failure can be sudden, and a red-hot bearing housing can ignite fine dust.

- It is advisable to enclose filters in a separate room with non-combustible walls and separate ventilation. In the event of a fire, this will allow flooding of just that small area. The raw material preparation area and the finished product storage should also be separated by fire-resistant walls.

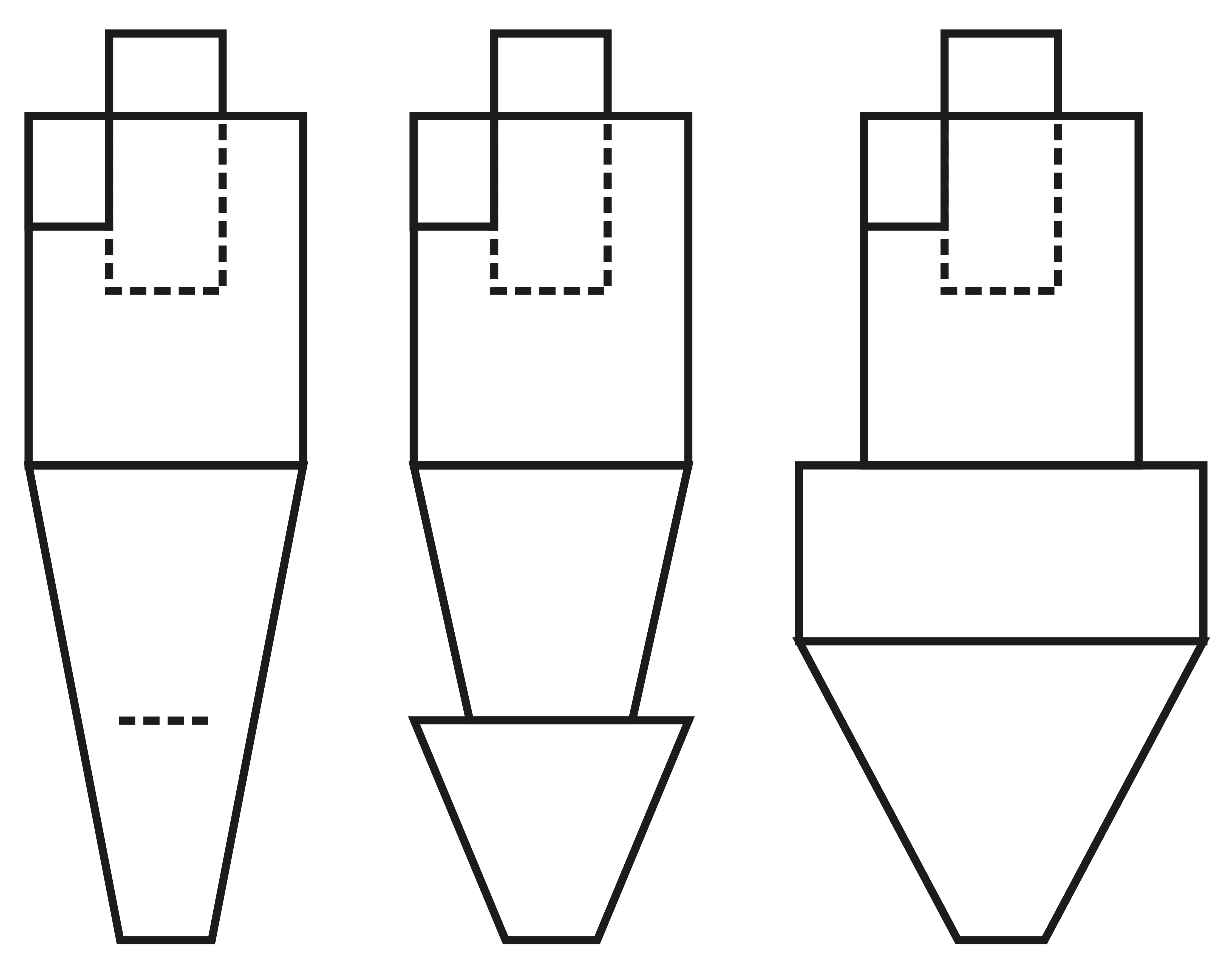

In the context of pellet production, an additional dust fan at the end of the pneumatic conveyor may be useful for delivering ground material to a greater height or significantly increasing productivity when set to the largest fraction size, although this is not the main advantage. The primary benefit of a screenless mill is that it does not release particles until they are fully ground, which is beneficial for achieving a relatively uniform mass of fractions. Furthermore, it does not have a rapidly wearing screen. Discharge of large particles can occur if the feed rate is too high, causing finer particles to drag larger wood chips along. Therefore, in the production of high-quality flour, it is advisable to include an inline sifter in the pneumatic system. By installing the finest mesh at a shallow angle to the flow, it can capture large particles and return them to the hammer mill's input with one-tenth of the processed air.

The full extent of this property was observed at one of the facilities where they began to deliver shavings from high-speed woodworking machines. The shavings were very fine, almost transparent, with a moisture content of 13-14%. A conventional hammer mill with a 5mm (0.2 inch) screen could only break down such raw material into fibers, turning the mass into something resembling cotton wool. The fibers would find any unevenness, fastenings, and protrusions, gathering into clumps. These clumps did not settle well in cyclones, clogged up sluice gates, and accumulated on the blades of the pellet mill's pressing unit, and most distressingly, they could not be extruded through the die. The pellet mill rollers would roll the fibers on the die, creating something like fiberglass, leading to emergency shutdowns. Installing a 4mm (0.16 inch) screen did not significantly change the situation but reduced the hammer mill's performance by threefold, partly due to increased moisture. After replacing the hammer mill with a screenless version and setting the fraction size to 1-2mm (0.04-0.08 inch), all the issues on the pelletizing line resolved themselves. Wet fibers, being much heavier, floated in the milling chamber until they dried out to 8-9% moisture. This effect is utilized in some types of dryers, which will be discussed in more detail in the relevant section.

The ability to balance not only the fraction size but also the moisture content helps process a mixture of dry and wet chips, although technologically this is not the best solution and can negatively affect pellet quality.

The price of such a shredder is both an advantage and a disadvantage. On one hand, it costs 2-3 times more than a conventional grain hammer mill with the same power. On the other hand, it is 2-3 times cheaper than a disintegrator or similar fine grinding mills with comparable power and productivity. Considering its resistance to damage from large pieces, the absence of a screen and belts as consumables, this type of shredder is quite justified for use in wood pelletizing lines and other relatively unpredictable types of biomass feedstock with low business margins, although its specific electricity consumption is significantly higher compared to screen hammer mills.