Screw or auger conveyors are among the simplest machines for transporting raw materials at an affordable price and relatively low energy consumption. Although there are many more surfaces rubbing against each other and the materials being moved, the specific load on these surfaces is quite low. Additionally, after operating with dry materials for a few days, the working surfaces usually polish to a mirror-like finish, which reduces the load several times.

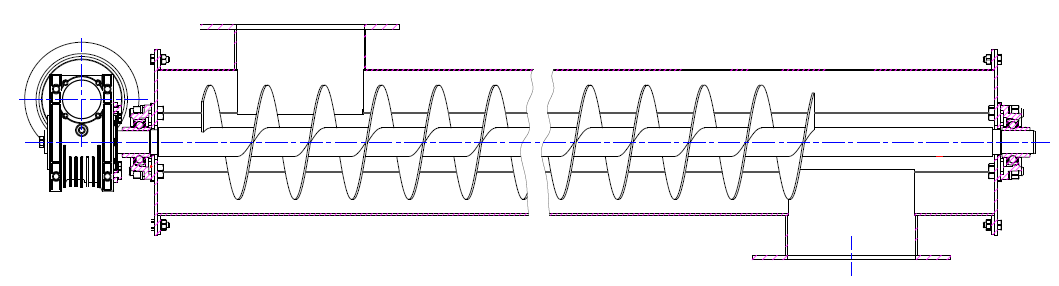

There are numerous methods to calculate a screw conveyor based on torsional load, capacity, pitch, and diameters. The good news is that ready-made helical spirals have long been popular, which when adjusted for mass-market use have standardized parameters for moving materials ranging from heavy and abrasive sand to soft food waste. Typically, these spirals have a pitch equal to the outer diameter, while the inner diameter corresponds to common water pipe sizes, about one-third of the outer coil diameter. To create a reliable device, you need to select a pipe of the correct size for the conveyor housing and a drive with the appropriate speed. This solution works well for both dry sawdust and wet wood chips. The thickness of these helical spirals is uneven and smoothly transitions from 4 mm (0.16 inches) at the inner edge to 2-2.5 mm (0.08-0.1 inches) at the outer edge, having almost perfect geometry compared to welded segments.

There are numerous methods to calculate a screw conveyor based on torsional load, capacity, pitch, and diameters. The good news is that ready-made helical spirals have long been popular, which when adjusted for mass-market use have standardized parameters for moving materials ranging from heavy and abrasive sand to soft food waste. Typically, these spirals have a pitch equal to the outer diameter, while the inner diameter corresponds to common water pipe sizes, about one-third of the outer coil diameter. To create a reliable device, you need to select a pipe of the correct size for the conveyor housing and a drive with the appropriate speed. This solution works well for both dry sawdust and wet wood chips. The thickness of these helical spirals is uneven and smoothly transitions from 4 mm (0.16 inches) at the inner edge to 2-2.5 mm (0.08-0.1 inches) at the outer edge, having almost perfect geometry compared to welded segments.

The screw is usually wound not up to the end of the housing but protrudes slightly into the discharge window. The last 20-50 mm (0.8-2 inches) of the spiral is bent to form a paddle, or a separate plate is welded on, so that compacted material in a "sausage" state breaks into clumps rather than hitting the end cover. This is especially useful when using the screw as a feeder for the even delivery of raw materials. If the conveyor's length-to-diameter ratio exceeds 10, it's preferable to have the winding near the intake window with a 1.5 times smaller pitch. This helps limit the screw's fill to 70% and reduces the likelihood of rotation jamming from clumped material.

Important point! Since the spiral can carry much more torque than the pipe welded to it, a much longer shaft stub should be machined for partial winding. Its end should go at least 200 mm (8 inches) deeper than the last coil and be welded with plug welds through holes in the pipe between the coils. Otherwise, the unreinforced and empty section of the pipe will be the weak point and will likely rupture if the screw exceeds 20 diameters of the flight.

Considering that in biofuel technologies, raw materials are relatively light and loose, screw conveyors generally do not require overly powerful bearing supports for conveyor lengths up to 6-8 meters (20-26 feet). For instance, a housed bearing like the F-206 can handle a radial load of 12 kN, equivalent to a weight of about 1.2 tons, while the axial load, based on engineering experience, typically accounts for 15-20% of the radial load. Consequently, a single such bearing can comfortably support a screw weighing 40-60 kg (88-132 pounds) with a 20 kg (44 pounds) drive and 20-30 kg (44-66 pounds) of raw material simultaneously inside the conveyor even when installed vertically. Also, such a housed bearing is adaptable to misalignments and forgives the deflection of the screw under its own weight without affecting its efficiency. Installing a complex bearing unit with multiple bearings, including thrust bearings, requires a much stiffer shaft, nontrivial clearance calculations for acceptable misalignments, and ultimately provides extended service life only due to a larger combined surface area for friction and grease reserve. Similarly, you could simply use a housing self-aligning bearing 1.5-2 times larger, along with a simple automatic lubrication unit.

For the longevity of the bearing, its protection from the raw material is much more important. This material inevitably gets squeezed through any seals. The simplest way is to leave a minimal gap between the end cap and the screw shaft. Place the bearing on a special support to allow small amounts of material to pass by it. This minimal gap can be ensured by a plastic insert, which has a hole slightly smaller in diameter than the shaft for a tight fit on the journal neck.

For the longevity of the bearing, its protection from the raw material is much more important. This material inevitably gets squeezed through any seals. The simplest way is to leave a minimal gap between the end cap and the screw shaft. Place the bearing on a special support to allow small amounts of material to pass by it. This minimal gap can be ensured by a plastic insert, which has a hole slightly smaller in diameter than the shaft for a tight fit on the journal neck.

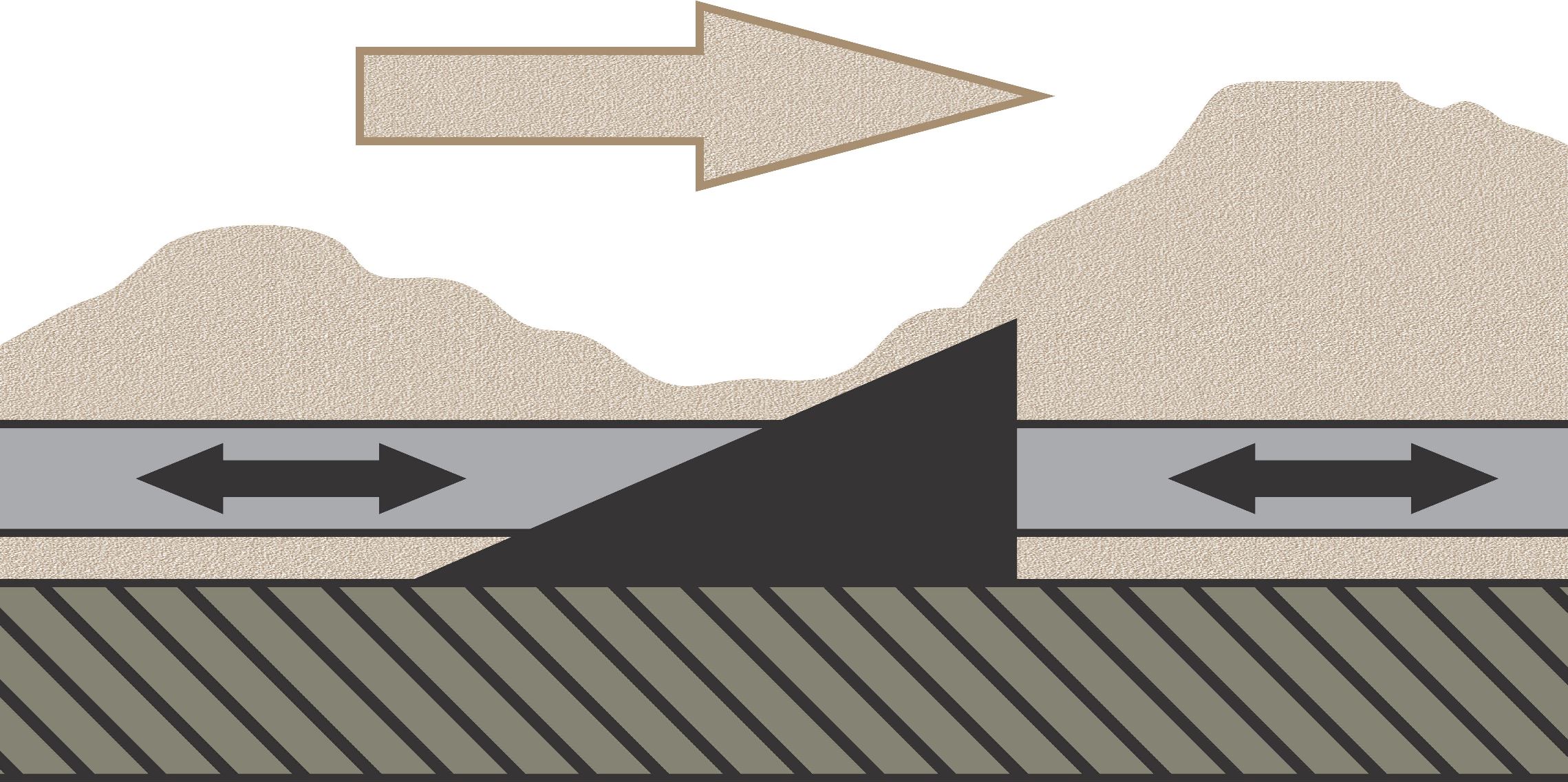

Screw conveyors can operate at any angle, and even vertically, provided that the gap between the coiled "flight" and the housing does not allow the material to fall back freely. Typically, the gap is chosen to prevent interaction between the screw and housing through material particles, often 1.5 to 2 times larger than the largest fraction. With an overly large gap and a slight incline, the problem is not so much transporting the material, but vault formation at the inlet, where clumps form along the walls and block the material from reaching the empty rotating flight. For vertical placement, as done in some types of feed mixers, the gap is minimized for maximum output. Vertical screws typically use higher rotational speeds to prevent material from settling on the flights. In inclined conveyors, the gap is increased to compensate for the sag of the screw under its own weight, preventing contact with the housing. It is highly inadvisable to use intermediate bearing supports for any abrasive materials since continuous lubrication is the only way to save them. A supportless option is more durable, where the screw contacts the housing only when empty, and "floats" when loaded.

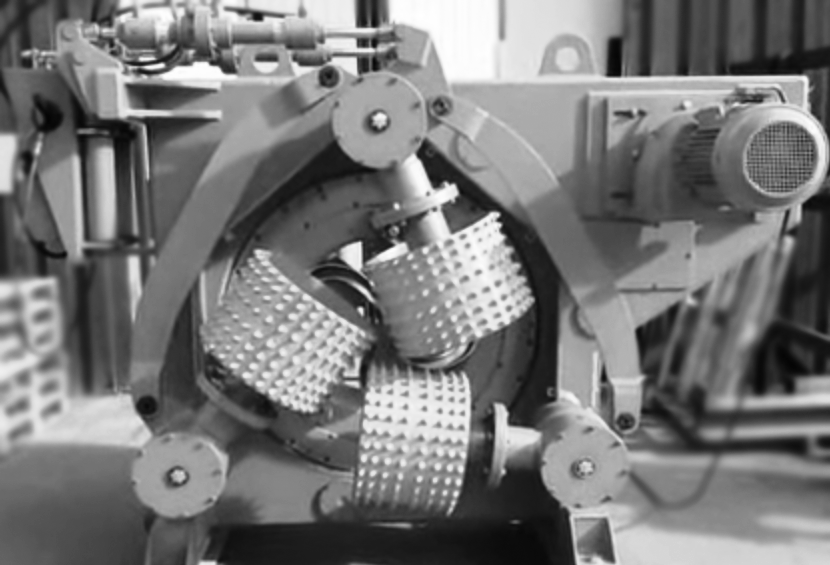

An interesting alternative to traditional screws is the shaftless or "spiral" type. It also uses a continuous spiral with a much thicker blade, capable of withstanding torsional loads without welding to a shaft or tube. Since there are many advantages to this design, it's easier to list them:

- Ability to push material of fairly large fractions with a minimal casing diameter. This is effectively used for feeding wood chips into furnaces, transporting and dosing abrasive materials like sand and coal.

- Low maintenance cost and easy replacement of the spiral. If a shaft requires careful manufacturing, the spiral can simply be cut to length and attached to one end of the conveyor with a special coupling.

- The absence of a second support allows its use in hot and aggressive environments without the hassle of maintenance.

- Possibility to use various flexible hoses from PVC, polyolefins, and other reinforced materials as the casing, which is useful for loading grain into transport vehicles or unloading various bulk materials at improvised storage sites.

For these conveyors, the drive is typically located at the material entry side, pushing the material away when the spiral rotates. Under load, the spiral compresses, reducing its diameter and moving away from the casing. This allows heavy materials like wood chips or coal to be transported horizontally without jamming when large chunks are encountered. The rotational speed for this is selected from 20 to 60 rpm. A drive can also be installed near the exit, requiring the proper gap with the casing for expansion deformation. These screws usually operate at 150-300 rpm with light loads, a solution popular for grain transfer using flexible conveyors, which can often work even in a vertical position of the upper section.

If shaftless slow-speed screws with thick steel spirals efficiently move wood chips, flexible grain screws are practically unsuitable for sawdust. Sawdust tends to clump, and it often contains large pieces of bark and cut-offs that can create blockages and sharply increase the load on the spiral and drive. This often leads to the breakage and deformation of the spiral and damage to the casing. Wood material is much cheaper and more abrasive than grain, so using flexible conveyors in pellet lines is not justified.

The main disadvantage of shaftless conveyors is the limitation of length depending on the thickness of the flight. For heavy or clumping materials, if the diameter-to-length ratio of the conveyor is less than 1:20, the spiral becomes too thick and expensive to transmit the required torque. Meanwhile, screws with a tube or rod along the axis can transmit higher torque because the screw flight enhances the shaft similarly to a gusset, distributing the load over a larger diameter. The second disadvantage stems from the first one: due to the spiral's elasticity under load, the flight pitch can also change, which under certain conditions can lead to pulsating material feed and the impossibility of using such a conveyor as a feeder. This effect usually manifests over a long conveyor length or when the material tends to jam.

An example of a successful application of a shaftless screw conveyor is a reactor for pyrolyzing wood chips. The reactor also acts as a conveyor with a length of 10-12 meters (33-39 feet) and a casing diameter of 600-700 mm (24-28 inches). In a shaftless design, it is possible to fill 80-90% of the volume, with no zones for sticking or accumulation of material, which is actively mixed during movement. At startup, the casing is heated by an external heat source, and during active pyrolysis, gases go into the furnace under the screws to heat incoming batches of wood chips. Thus, the spiral is affected by various temperatures, humidities, and other factors, ensuring continuity and cost-effectiveness compared to retort and drum installations.

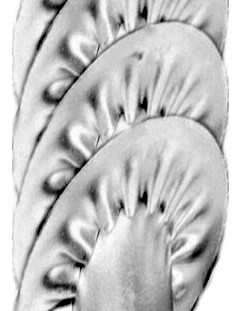

For setting up mass production of screws in a semi-handcrafted manner, metallic strips are corrugated at the edge. When angles of about 60° are achieved, the edge length is halved, and at 70°, it is reduced by three times. Usually, only up to 30% of the strip's width is subject to the action of toothed rolls, while the remaining part is stretched. The strip is usually up to 1.5 mm (0.06 inches) thick, and the pipe has minimal wall thickness for its nominal diameter. The corrugated part, after welding, adds stiffening similar to gussets. This method produces cheap and lightweight screws, used for moving grain in harvesting machines where lightness and operation at relatively high speed are essential.

For setting up mass production of screws in a semi-handcrafted manner, metallic strips are corrugated at the edge. When angles of about 60° are achieved, the edge length is halved, and at 70°, it is reduced by three times. Usually, only up to 30% of the strip's width is subject to the action of toothed rolls, while the remaining part is stretched. The strip is usually up to 1.5 mm (0.06 inches) thick, and the pipe has minimal wall thickness for its nominal diameter. The corrugated part, after welding, adds stiffening similar to gussets. This method produces cheap and lightweight screws, used for moving grain in harvesting machines where lightness and operation at relatively high speed are essential.

In pellet production, the use of such screws is limited for several reasons. Firstly, the thin flight is prone to deformation, and sawdust almost always forms clumps between the screw edge and the casing. Secondly, the wavy surface promotes material sticking, especially when wet. Therefore, these screws should be used for small-sized material when visual control is possible, such as collecting chips falling from a storage bin. They are also suitable for collecting dry fine sawdust and dust from aspiration systems.