Attempts have been made to dry chips with a main fraction of 50 mm (2 inches), which leads to the surface drying excessively to a moisture content of 3-5%, while leaving the internal fiber moisture at 15-20%. This not only significantly increases the load on the hammer mill for dry raw materials but also affects the technological properties of the resulting sawdust. Over-dried fibers are ground to a powder, hindering adhesion, and moist fibers cause internal breakage in the pellet during compression, leading to a large number of cracks and reduced pellet strength. As a makeshift solution, the concept of "maturation" of raw material has been developed, where it is held between drying and pelletizing for 2 to 6 hours, which incurs noticeable additional capital costs for organizing automated warehouses with hydraulic stoker floors. In addition to the maintenance losses of these warehouses, energy losses during pelletizing become apparent, as raw material often cools down in winter and requires increased load on the pressing unit or increased boiler power for heating. A particular inconvenience for the operator is the inability to adjust the drying mode based on pellet quality in real-time.

Grinding chips down to the "needle" or "broken matchstick" fraction significantly increases the surface area of particles, which speeds up drying and enhances the performance of most types of dryers. With less thickness, heating occurs much more uniformly across the volume, leading to sufficient moisture leveling between individual fibers. Preliminary grinding also removes dirt fragments, opens pores in bark pieces, and collectively facilitates the separation of mineral impurities after drying, reducing the ash content of the pellets.

Wet Chips in Sieving Crushers

When grinding sufficiently small chips, efforts are made to adjust the process so that splitting occurs mainly along the fibers, while grinding and tearing of fibers are minimized to avoid excess energy consumption. This process is achievable by minimizing the residence time in the grinding chamber using three methods:

When grinding sufficiently small chips, efforts are made to adjust the process so that splitting occurs mainly along the fibers, while grinding and tearing of fibers are minimized to avoid excess energy consumption. This process is achievable by minimizing the residence time in the grinding chamber using three methods:

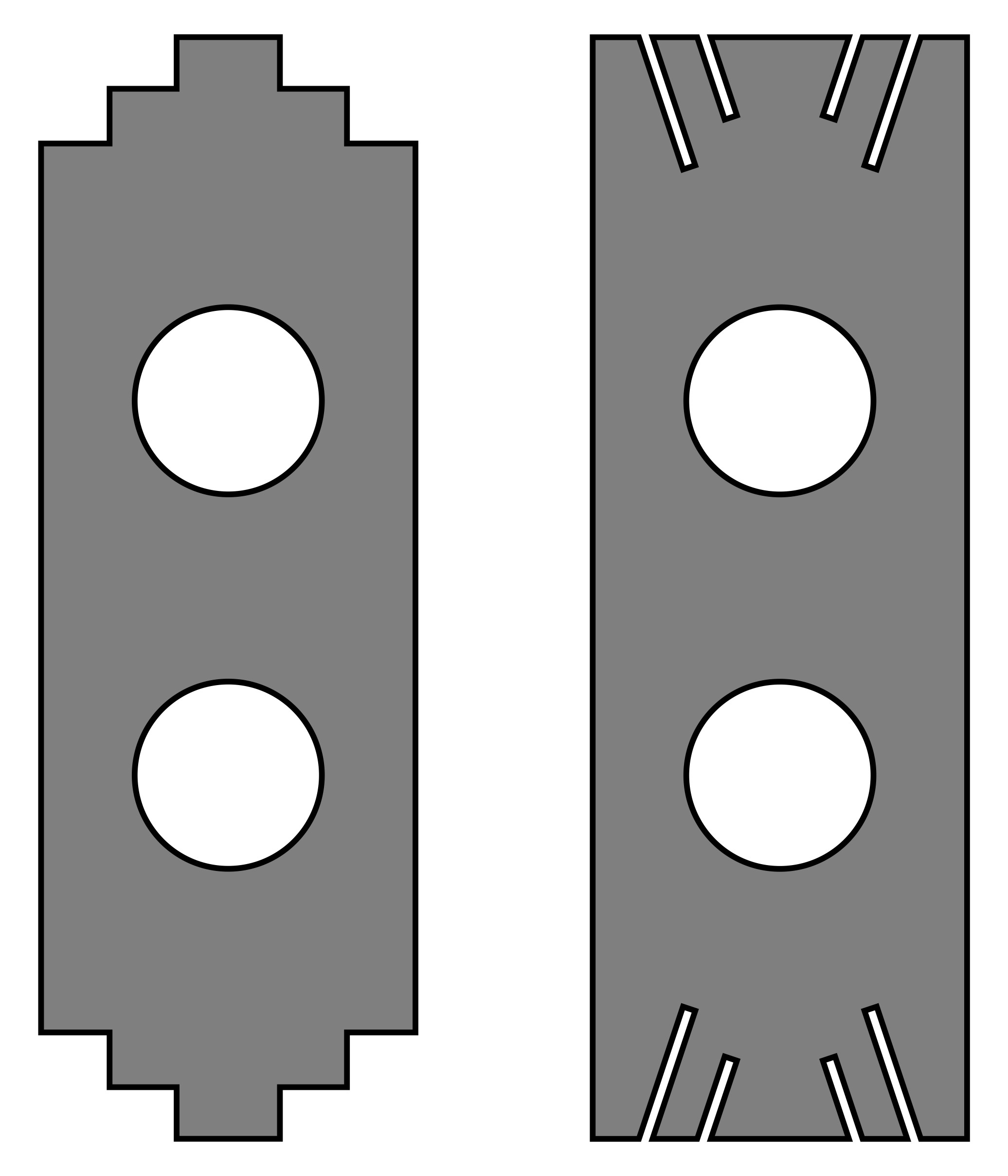

- Increase the specific sieving area by 3-4 times in traditional sieving crushers

- Increase the volume of air for pneumatic transport through the crusher by 2-4 times

- Use of sieveless, so-called inertial crushers

Increasing the sieving area actually entails the use of crushers significantly larger in size and cost. They also need to be designed with specific options: additional augers for cleaning the space under the sieves, additional openings for air supply to prevent sticking on walls and doors. Increasing the airflow not only impacts the cost of the grinding section but also prescribes increased energy consumption regardless of the amount of raw material fed.

If the raw material contains coniferous bark, its crushing generates a highly sticky suspension of resinous particles, which easily forms deposits both immediately behind the sieve on the surfaces of the housing and transport systems, and at the bends of the air ducts with cyclones. When working with frozen raw material at temperatures below -25°C (-13°F), another effect occurs: the hammer's impact causes the moisture on the chip surface to melt, and as soon as the crushed material becomes stationary in the hopper, it refreezes within 10-15 minutes in the absence of agitation. The bonding of the mass is comparable to high-quality construction mixtures, and removing a piece with a volume of about half a cubic meter (18 cubic feet) can take 1-2 hours of work time. Such clumps can also form in pneumatic transport cyclones and temporarily halted chain conveyors. To avoid such cases, it is highly discouraged to use pneumatic transport when crushing raw chips, and if possible, it's better not to use a buffer hopper before the dryer. The feed to the dryer can be regulated from the hopper with the initial chips, and the chain conveyor between the chip crusher and dryer should be as short as possible and operate continuously, regardless of raw material feed. With a properly selected crusher providing a good chip fraction, its productivity reserve will suffice for the dryer.

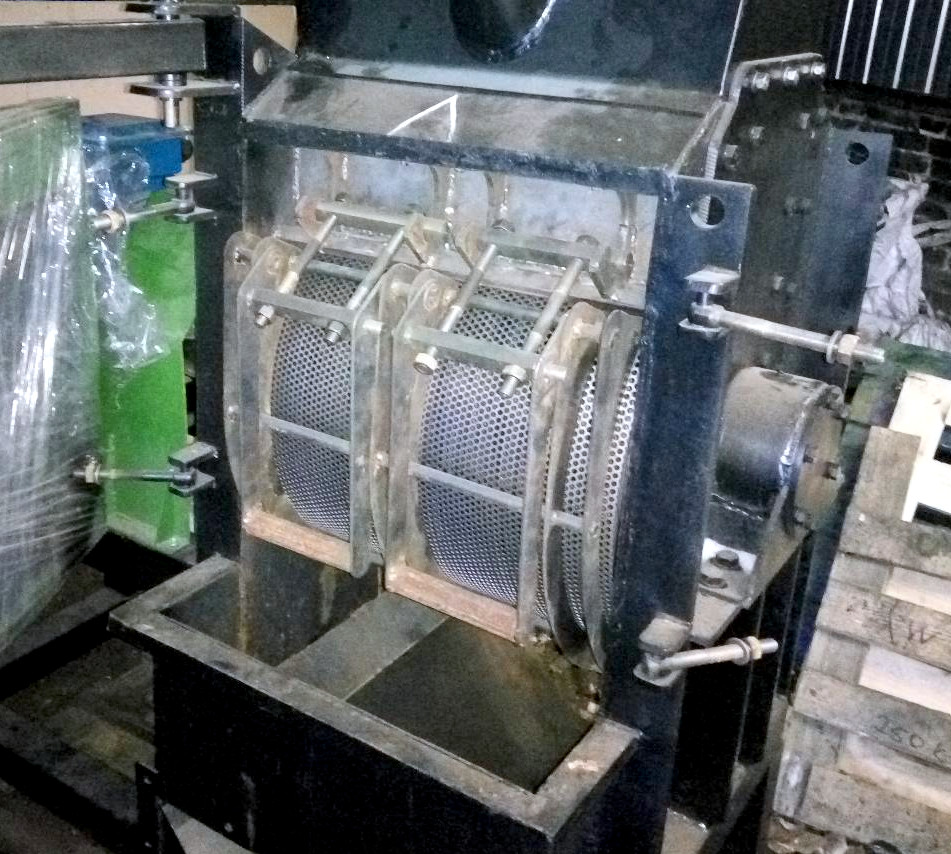

Inertia or Grate-Free Hammer Mills

Inertia or grate-free mills consist of a cylindrical housing and a rotor with hammers. The housing has a feed hopper at one end and an outlet tube at the other. Inside the housing, blades are installed at an angle, promoting material movement from inlet to outlet. The resulting fraction is typically defined by the distance from the hammer's edge to the housing or liners. There are also designs where combs for more intensive grinding are installed in the housing slots, with their depth of engagement between the hammers adjustable from the outside.

Inertia or grate-free mills consist of a cylindrical housing and a rotor with hammers. The housing has a feed hopper at one end and an outlet tube at the other. Inside the housing, blades are installed at an angle, promoting material movement from inlet to outlet. The resulting fraction is typically defined by the distance from the hammer's edge to the housing or liners. There are also designs where combs for more intensive grinding are installed in the housing slots, with their depth of engagement between the hammers adjustable from the outside.

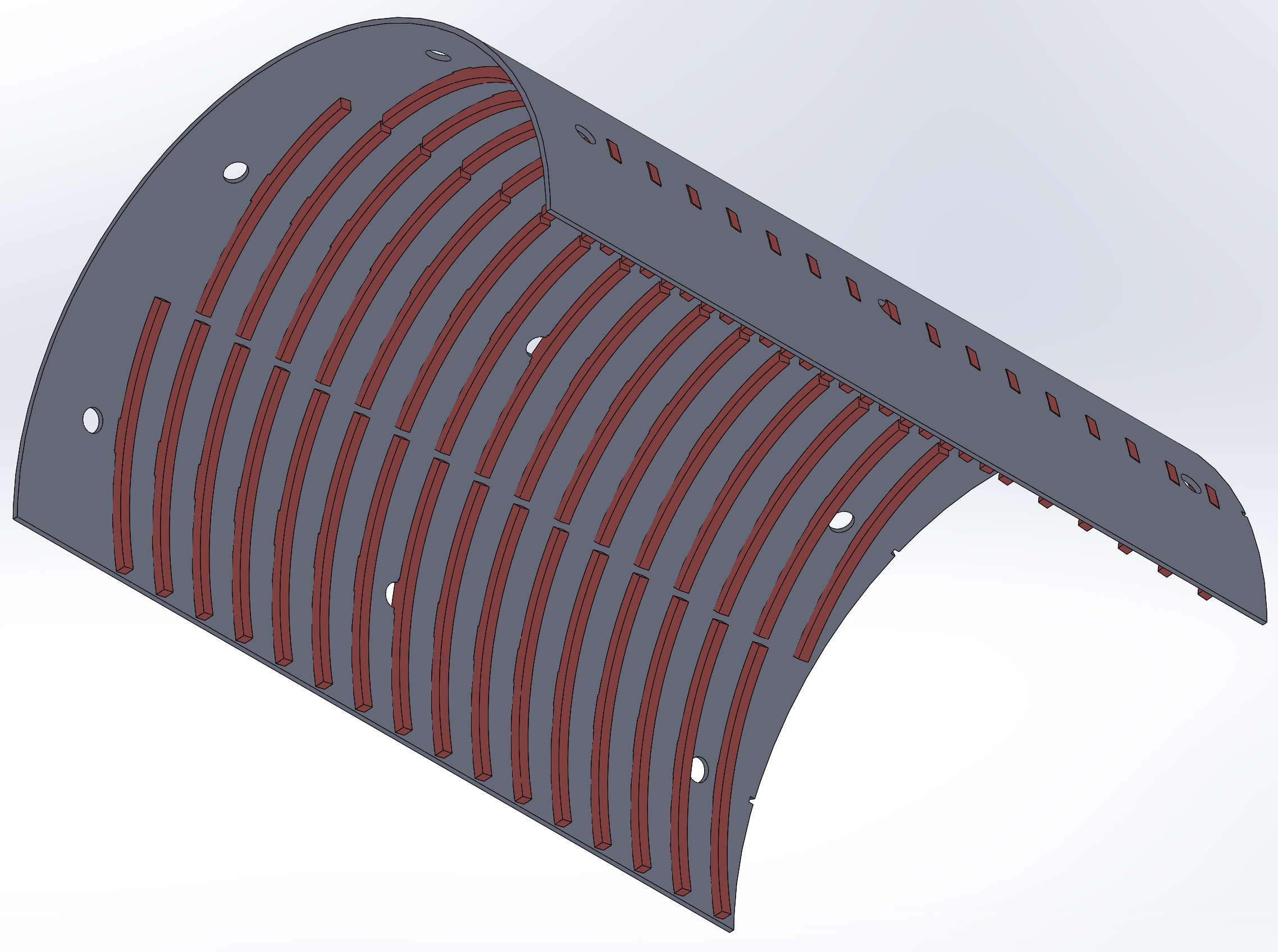

The most reliable models are equipped with welded or cast liners that protect the housing from wear. Welded liners are made from pre-cut sheets with slots, rolled into a cylinder. Their lifespan is relatively short, ranging from one to three months of continuous operation, and they can be manufactured onsite using metal rolls and welding equipment. Cast liners are made from wear-resistant cast iron and last up to one year of continuous operation.

The most reliable models are equipped with welded or cast liners that protect the housing from wear. Welded liners are made from pre-cut sheets with slots, rolled into a cylinder. Their lifespan is relatively short, ranging from one to three months of continuous operation, and they can be manufactured onsite using metal rolls and welding equipment. Cast liners are made from wear-resistant cast iron and last up to one year of continuous operation.

Performance and fraction also heavily depend on the angle of the guiding blades or notches on the liners. With homogeneous and sufficiently fine initial chips of 20-30 mm (0.8-1.2 inches), maximum performance is achieved at an angle of 15-20°. If large sticks and pieces of bark are often present in the initial chips, the highest quality product is obtained at a notch angle of about 10°. Further reduction of the angle does not aid grinding and leads to excessive electricity consumption. Increasing the angle above 20° facilitates adhesion of material to the liners, up to the complete clogging of gaps by particles of wood glued with resin and ice, and the cessation of material discharge.

The provided angles are based on a hammer speed of about 100 m/s (328 ft/s), and experiments were conducted to produce high-quality raw material for fuel pellets. Similar grinders are often used with a hammer speed reduced by half for crushing large pieces of bark into an acceptable fraction, which does not clog feeders in boiler houses.

Discharge from such mills typically occurs directly into a closed chain conveyor or hopper with active agitation, followed by feeding into a dryer or furnace. It is highly discouraged to discharge into screw conveyors or stoker bins, as freezing and adhesion occur within the first hour of operation.

The most effective hammers have a thickness of about 5 mm (0.2 inches). As they wear, they round off and self-sharpen, allowing for partial chopping of the raw material. Thinner hammers wear out too quickly, while thicker ones allow uncrushed material to pass through. Sometimes, it is justified to install the first rows of hammers with a thickness of 10 mm (0.4 inches) while simultaneously protecting the inlet nozzle with a baffle. Such a hammer mill can handle the largest wood chips and trimming waste with maximum dimensions of 100x200x25 mm (4x8x1 inches).

The normal energy consumption for crushing 1 ton (2204 pounds) of wood chips with an initial particle size of 30 mm (1.2 inches) is 10 kWh. Considering that 2.5 tons (5512 pounds) of raw wood are needed for 1 ton (2204 pounds) of pellets, a hammer mill for raw wood chips with a power rating of 37 kW should be included in a pellet line with a production capacity of 1 ton per hour. It would operate at an average load of 70% of its nominal capacity.

Grinding in Flat Die Pellet Mills

An unusual method is to compress raw wood chips and other fibrous material through a die with holes. This method is fully functional and successful because the rollers in a pellet mill can create pressure up to 400 kg/cm² (5690 psi), and the pressure at the hole edges is even higher. The grinding process is slow, not requiring high speeds or large volumes of air flow, so the efficiency of such grinding is near perfect. The only disadvantage is the high cost of the pellet mill compared to a hammer mill. However, when compared to a complete grinding system, which includes a hammer mill, pneumatic transport, and other auxiliary and output equipment, the difference doesn't seem so drastic.

Since moist raw material imposes significantly less load during grinding than dry material during pelletizing, the entire pellet mill, including the die, rollers, and bearings, lasts much longer, and the unit cost of consumables per ton of raw material can compare to grinding with hammers, while electricity consumption is noticeably lower.