Any contact of raw material with the metallic surfaces of equipment leads to wear and the entry of particles into the raw material. A large portion of magnetic impurities comes from the wear of hammer mill working parts, the abrasion of screw conveyor flights and casings, and as fragments of knives and hammers, loosened fasteners, or simply random parts of equipment or vehicles. Large pieces can damage hammer mill hammers upon impact, sometimes leading to the cascading shattering of hardened components. Bolts and pieces of steel plates can jam a screw or throw a chain off a sprocket in transportation systems. Steel parts larger than 5mm (0.2 inches) can block the dies of a ring die, reducing throughput and applying intensive impact load on rollers that will unsuccessfully attempt to push material through with each die rotation. Fine metal dust is prohibited in animal feed as it can cause digestive issues and significant losses for farms.

Since wear and human factors are inevitable in any production, the only effective countermeasure is to install magnets along the raw material flow path. Depending on the particle size separated by magnetic systems, continuous magnetic separators, magnetic columns, and magnetic grates are used. All of them operate based on the ability to attract iron-containing alloys in a magnetic field, hence they are also known as iron separators.

Magnetic Separators

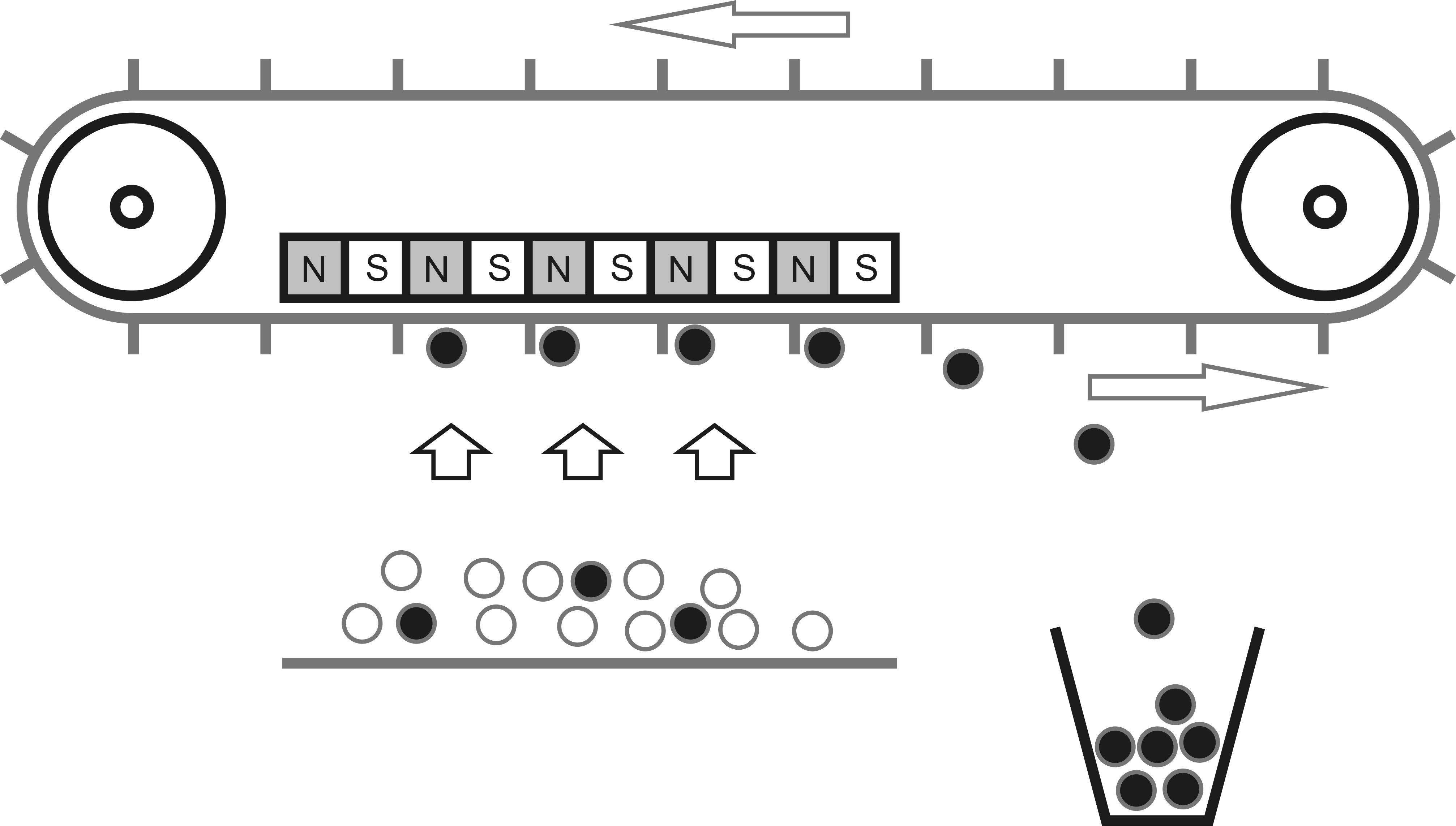

Magnetic separators can continuously separate steel inclusions at any percentage present in the raw material. Typically, a belt conveyor with a scraper is used, under which a powerful magnetic plate or electromagnet is embedded. This separator is installed above the freely sagging belt with raw material, picking up particles vertically or placed near the descending flow of raw material to attract particles horizontally. Bolts and other fasteners stick to the belt, which slides off the magnet and carries all the caught items into a separate trolley or container. Such devices are commonly used to mass-extract nails and other fasteners when processing pallets, as they contain at least 300 grams (0.66 pounds) of nails per 18-20 kg (40-44 pounds) of wood. The large plate area allows for thorough extraction not only of clean nails but also of chips with embedded metal.

Magnetic separators can continuously separate steel inclusions at any percentage present in the raw material. Typically, a belt conveyor with a scraper is used, under which a powerful magnetic plate or electromagnet is embedded. This separator is installed above the freely sagging belt with raw material, picking up particles vertically or placed near the descending flow of raw material to attract particles horizontally. Bolts and other fasteners stick to the belt, which slides off the magnet and carries all the caught items into a separate trolley or container. Such devices are commonly used to mass-extract nails and other fasteners when processing pallets, as they contain at least 300 grams (0.66 pounds) of nails per 18-20 kg (40-44 pounds) of wood. The large plate area allows for thorough extraction not only of clean nails but also of chips with embedded metal.

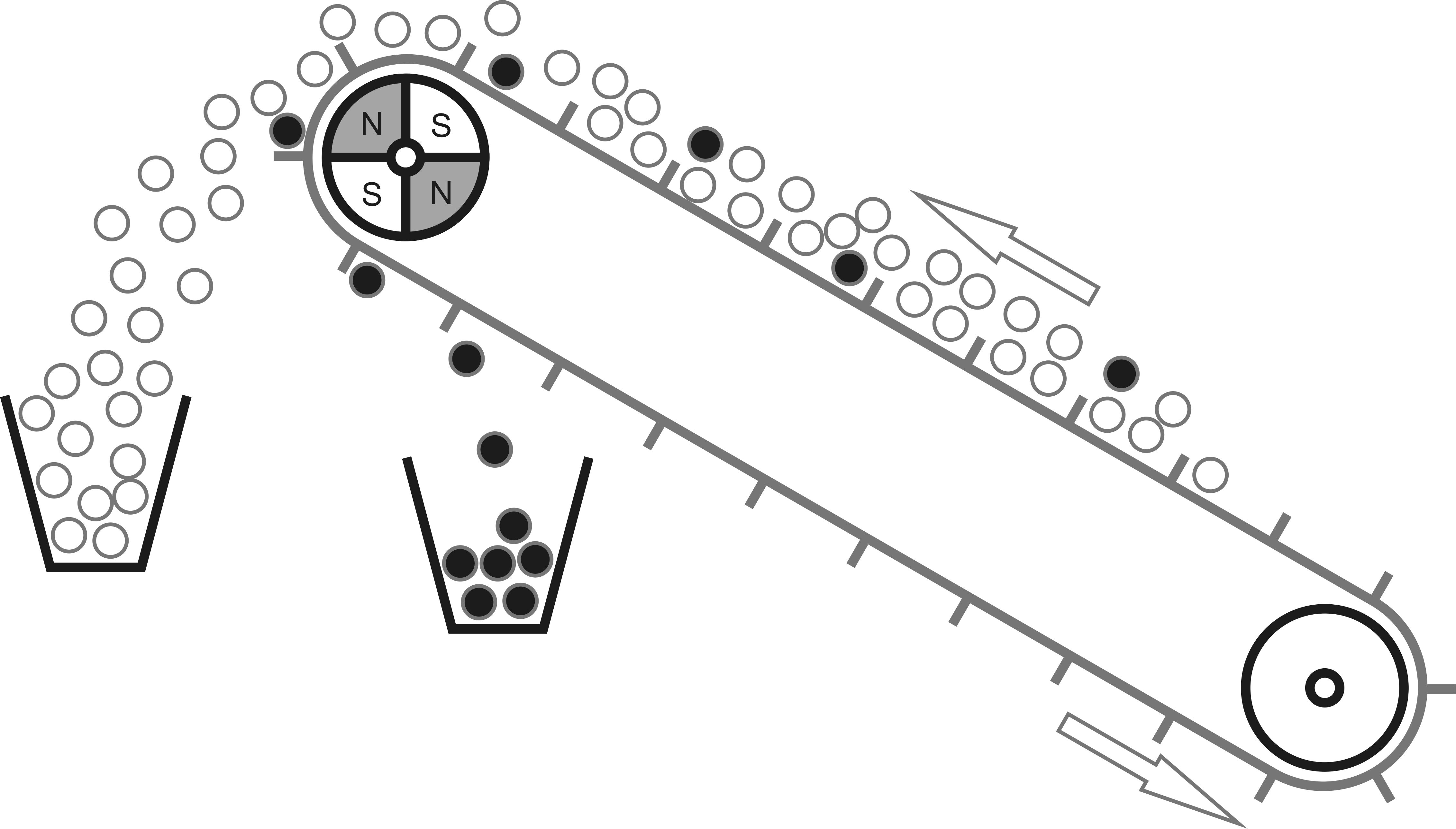

Sometimes an existing belt conveyor is converted into a magnetic separator by replacing the top drum with a system of magnets. Most of the raw material follows a parabolic trajectory into the next conveyor or hopper, while iron-containing parts fully wrap around the drum and separate from the belt underneath, falling into a chute and container. This solution is usually noticeably cheaper than installing a separate full-fledged separator, but its efficiency decreases significantly with thicker layers, especially when separating metal dust from fine raw material.

Sometimes an existing belt conveyor is converted into a magnetic separator by replacing the top drum with a system of magnets. Most of the raw material follows a parabolic trajectory into the next conveyor or hopper, while iron-containing parts fully wrap around the drum and separate from the belt underneath, falling into a chute and container. This solution is usually noticeably cheaper than installing a separate full-fledged separator, but its efficiency decreases significantly with thicker layers, especially when separating metal dust from fine raw material.

Both options can separate not only iron inclusions but also non-ferrous metal pieces as small as 3mm (0.12 inches) if inductive coils, instead of a magnetic system, are used with a specific signal applied to them. The resulting eddy currents repel, lift, or otherwise affect the particles, enabling the separation of the raw material flow and impurities. Waste recycling plants customarily use magnetic and eddy-current separators in sequence to fully free raw material from the majority of metal impurities.

Magnetic Columns

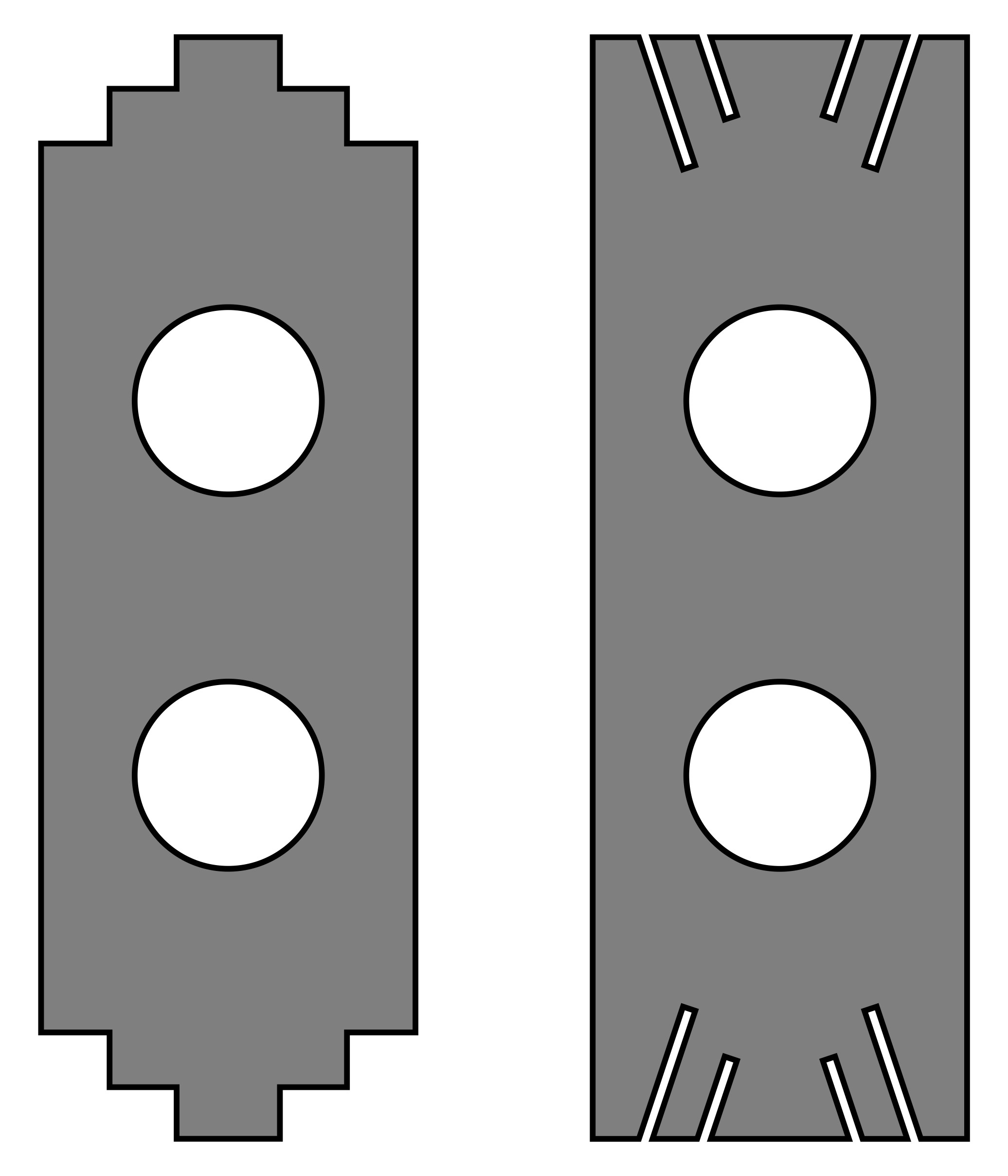

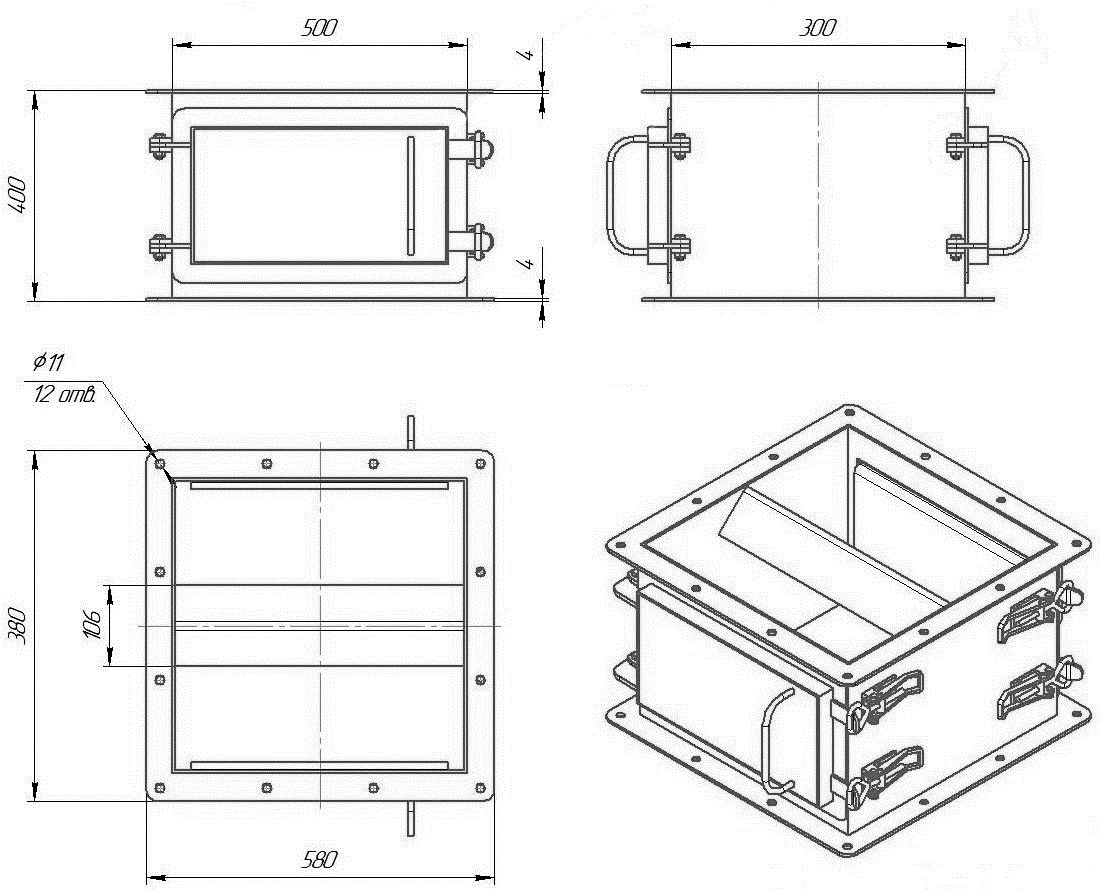

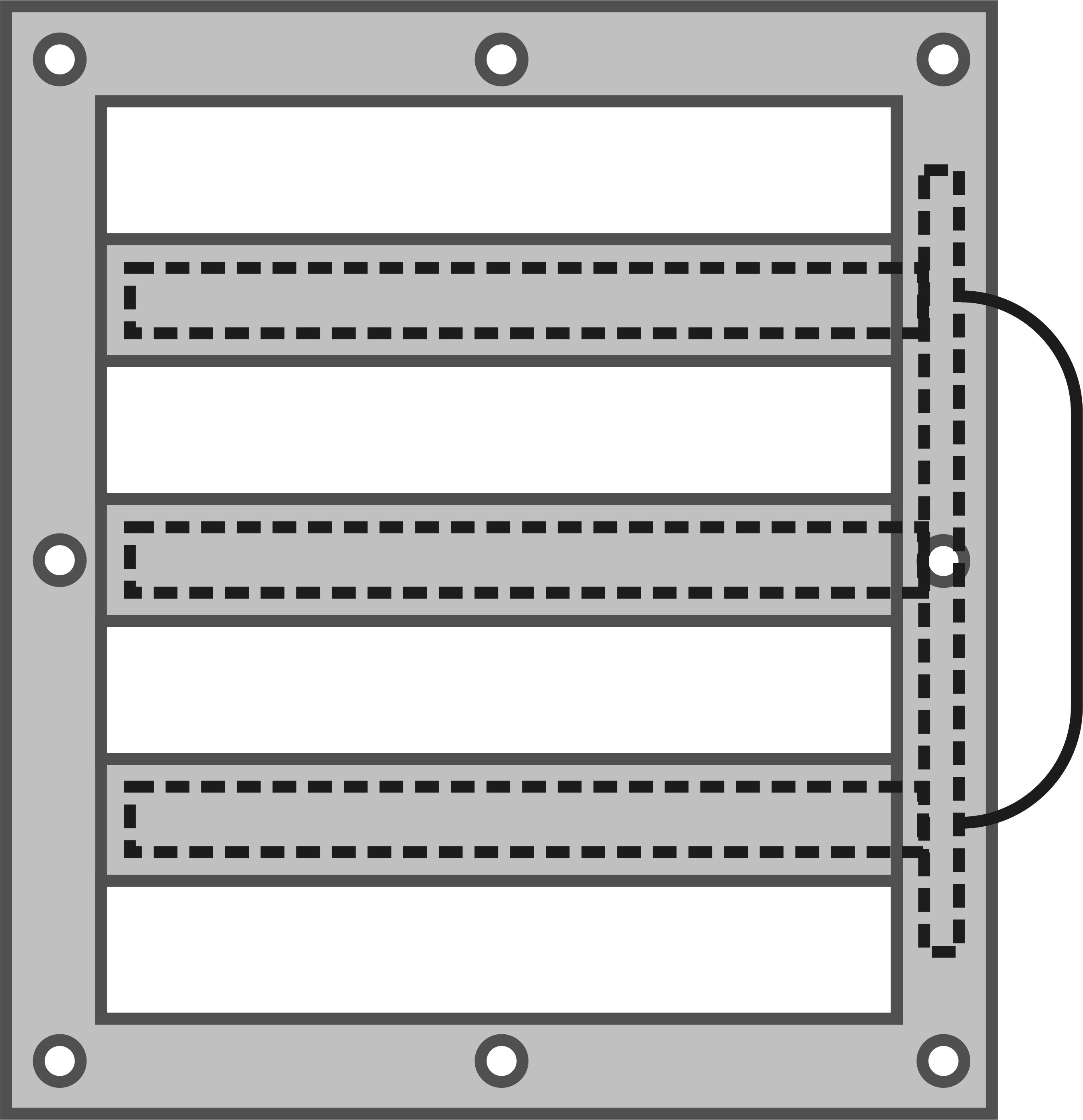

Magnetic columns are much simpler and cheaper than separators but are intended for catching occasionally passing metal fasteners. They are enclosed structures with inlet and outlet mounting flanges and cleaning doors. These are installed strictly vertically, either under gate valves or at the exit of various conveyors, meaning in places where the free-fall speed of the material is low. The housing is usually made of non-magnetic material like stainless steel or aluminum, and powerful magnetic systems are installed on the doors. A diverter is located at the center of the housing, right below the inlet flange, directing the flow of raw material closer to the magnetic plates. Experiments with an open magnetic plate measuring 300x500mm (12x20 inches) showed that a bolt falling from a height of 1 meter (3 feet) does not pass beyond 400mm (16 inches) from the plate without being caught. The column width usually does not exceed 300mm (12 inches), and considering the diverter, the layer of passing material is only about 100mm (4 inches), which practically guarantees the removal of unwanted magnetic impurities.

Magnetic columns are much simpler and cheaper than separators but are intended for catching occasionally passing metal fasteners. They are enclosed structures with inlet and outlet mounting flanges and cleaning doors. These are installed strictly vertically, either under gate valves or at the exit of various conveyors, meaning in places where the free-fall speed of the material is low. The housing is usually made of non-magnetic material like stainless steel or aluminum, and powerful magnetic systems are installed on the doors. A diverter is located at the center of the housing, right below the inlet flange, directing the flow of raw material closer to the magnetic plates. Experiments with an open magnetic plate measuring 300x500mm (12x20 inches) showed that a bolt falling from a height of 1 meter (3 feet) does not pass beyond 400mm (16 inches) from the plate without being caught. The column width usually does not exceed 300mm (12 inches), and considering the diverter, the layer of passing material is only about 100mm (4 inches), which practically guarantees the removal of unwanted magnetic impurities.

When installing a magnetic column, you must apply sealant not only to the flange edges but also around the doors. Periodic cleaning of the magnets using dust protection PPE is typically done during a short production stop at shift change, as the wide swinging of the door facilitates and speeds up maintenance. If the contamination level requires more frequent cleaning, it's better to replace the column with an automatic separator.

Magnetic Grids

Magnetic grids are even more compact devices, consisting of a thick flange, usually up to 50mm (2 inches) in height, with magnetic rods placed within the perimeter. These are installed in breaks between different machines, but it is also preferable for the material flow to fall freely perpendicular to the flanges at low speed. In pneumatic transport systems, efficiency drops significantly not only due to the speed of passing magnetic particles but also because the fast flow of material can scrub settled impurities away. Grids are most effective for removing steel dust inclusions in fine dry materials and are installed after crushers, mills, pellet grinders, pellet mills, and other equipment whose wear generates such contamination. Since it’s quite difficult to clean the rods even when removed from the flange, they are usually placed inside tubes welded into the flange from non-magnetic material. For cleaning, a bucket is placed underneath, and when the rods are removed, all captured matter is carefully dumped and brushed off.

Magnetic grids are even more compact devices, consisting of a thick flange, usually up to 50mm (2 inches) in height, with magnetic rods placed within the perimeter. These are installed in breaks between different machines, but it is also preferable for the material flow to fall freely perpendicular to the flanges at low speed. In pneumatic transport systems, efficiency drops significantly not only due to the speed of passing magnetic particles but also because the fast flow of material can scrub settled impurities away. Grids are most effective for removing steel dust inclusions in fine dry materials and are installed after crushers, mills, pellet grinders, pellet mills, and other equipment whose wear generates such contamination. Since it’s quite difficult to clean the rods even when removed from the flange, they are usually placed inside tubes welded into the flange from non-magnetic material. For cleaning, a bucket is placed underneath, and when the rods are removed, all captured matter is carefully dumped and brushed off.