Shredders are machines for grinding bulk materials, where the tearing action on the material prevails over cutting. The use of sharp knives enhances the grinding efficiency.

Twin-Shaft Shredders offer the highest productivity per kilowatt of energy consumed. Despite their apparent simplicity and versatility, they have many design features tailored to each type of material and working condition.

Twin-Shaft Shredders offer the highest productivity per kilowatt of energy consumed. Despite their apparent simplicity and versatility, they have many design features tailored to each type of material and working condition.

The gap between the blades determines the cutting characteristics of the assembly. The softer the material, the smaller the gap and the less frequent the need for sharpening. The number of teeth on each blade is dictated by both the bulk density and the strength of the raw material. The illustration shows an assembly for shredding pallets, featuring a large number of teeth for quick intake of wood debris and bulky crates. Blade thickness is 50 mm (2 inches), and the close fit ensures a fraction size of 40-60 mm (2-3 inches). Using a shredder with a universal assembly for municipal solid waste will result in large, chewed-like wood pieces. Such products are inefficient to separate from nails, prone to clog in hopper feeders, and difficult to grind further. Assemblies with blades having 1-2 teeth are usually used for shredding metal items, and their productivity on wood material will be very low.

These shredders often feature automation that enables reverse motion when a piece is too large or hard. This is justified for work with municipal solid waste but significantly reduces productivity on wood. When testing functionality, it's essential to load relatively intact pallets, ensuring the drive load remains within 70-80% of the nominal. This will indicate a proper blade formula calculation – thickness, diameter, number of teeth, and rotational speed.

The use of a screen right under the blade assembly is justified for universal use with municipal solid waste and scrap metal. For wood shredding, a screen tends to be an obstacle; it either clogs quickly in high humidity or becomes useless with too large mesh sizes.

The efficiency of twin-shaft shredders is significantly increased by integrating the shafts into a gear transmission with a small difference in the gear diameters. For instance, with a 5:6 gear tooth ratio, the force between the meshing teeth rises sixfold compared to the torque of the motor reducer. A tooth of one shaft will slowly catch up with a tooth of the other shaft, and upon meeting, it will slowly and steadily shear through the material with a much greater force. This design effectively handles relatively loose material containing strong fibers or metal wire and nails, combining high productivity with resistance to jamming. Design calculations should consider the increased load on the shafts, bearings, and supports, adjusting their thicknesses and ratings to the appropriate sizes. This approach helps to tackle the ongoing challenge of twin-shaft shredders, where adjustments in shaft length, cutter diameter, drive power, and rotational speed are needed to adapt to varied raw materials.

Single-Shaft Shredders typically feature a hydraulic pusher for periodically pressing material against the rotor with blades. This is the most versatile shredder option for various materials with a wide range of automation options and capabilities, both in hydraulic control and knife, screen, and operational hopper geometry adaptability.

Single-Shaft Shredders typically feature a hydraulic pusher for periodically pressing material against the rotor with blades. This is the most versatile shredder option for various materials with a wide range of automation options and capabilities, both in hydraulic control and knife, screen, and operational hopper geometry adaptability.

At the edge of the pusher, a counter-knife is installed, which has a toothed shape that mirrors the profile of the knives on the rotor. The fraction size is determined by the mesh size of the screen that encases the rotor. Large parts are ejected back into the grinding chamber, fitting into the gap between the knives and the counter-knife. This design feature allows for obtaining quite fine fractions of fibrous material by holding the pusher in its extreme position for a few seconds during each pass. The automation also slows down the movement when the main drive is overloaded.

For loose materials like pallets and boxes, there are several methods to increase productivity without upgrading to a larger, more expensive model:

- Increasing the number of knives

- Increasing the length of the hopper and the stroke of the hydraulic pusher to capture larger pallets

- Increasing the rotation speed and power of the engines

- Increasing the speed of the hydraulic pusher’s pressing of the material to the rotor

- Doubling the return stroke speed of the pusher to reduce idle time by 30-40%

If most of the raw material has a maximum size of up to 500 mm (20 inches) and pallets are only occasionally encountered, it is more beneficial to install a small shredder and cut large pieces with a circular saw. There are very budget-friendly options for single-shaft shredders with gravity feed and drive power from 3 to 22 kW. Material capture in these is extremely unstable, and such a solution may be suitable for occasional disposal of a few pallets. Achieving stable operation with sufficient productivity for a pellet line is practically impossible, and regular manual pushing of material is likely to lead to accidents.

The main disadvantage of a single-shaft shredder is that it is the most expensive option relative to productivity. Although it is possible to achieve a fairly fine fraction right away, one should not use too fine a screen for raw wood and other fibrous materials, as this will lead to a sharp drop in productivity. The second disadvantage is that hydraulics are indispensable, requiring appropriate qualification and a responsible approach for maintenance, as well as additional options for extremely hot or cold climates.

Drum Shredders are a modification of the classic drum chipping machine for processing wooden pallets, where instead of attaching 2-4 knives to the drum, several dozen holders of small teeth of various shapes are welded. If the goal is to reduce waste volume, pointed hooks are used for active pulling, splitting, and breaking of the wood. If further deep processing is intended, knives similar to those on a single-shaft shredder are installed. In this case, active additional grinding of the mass occurs on the screen under the drum, and the subsequent separation of nails poses no difficulties.

Drum Shredders are a modification of the classic drum chipping machine for processing wooden pallets, where instead of attaching 2-4 knives to the drum, several dozen holders of small teeth of various shapes are welded. If the goal is to reduce waste volume, pointed hooks are used for active pulling, splitting, and breaking of the wood. If further deep processing is intended, knives similar to those on a single-shaft shredder are installed. In this case, active additional grinding of the mass occurs on the screen under the drum, and the subsequent separation of nails poses no difficulties.

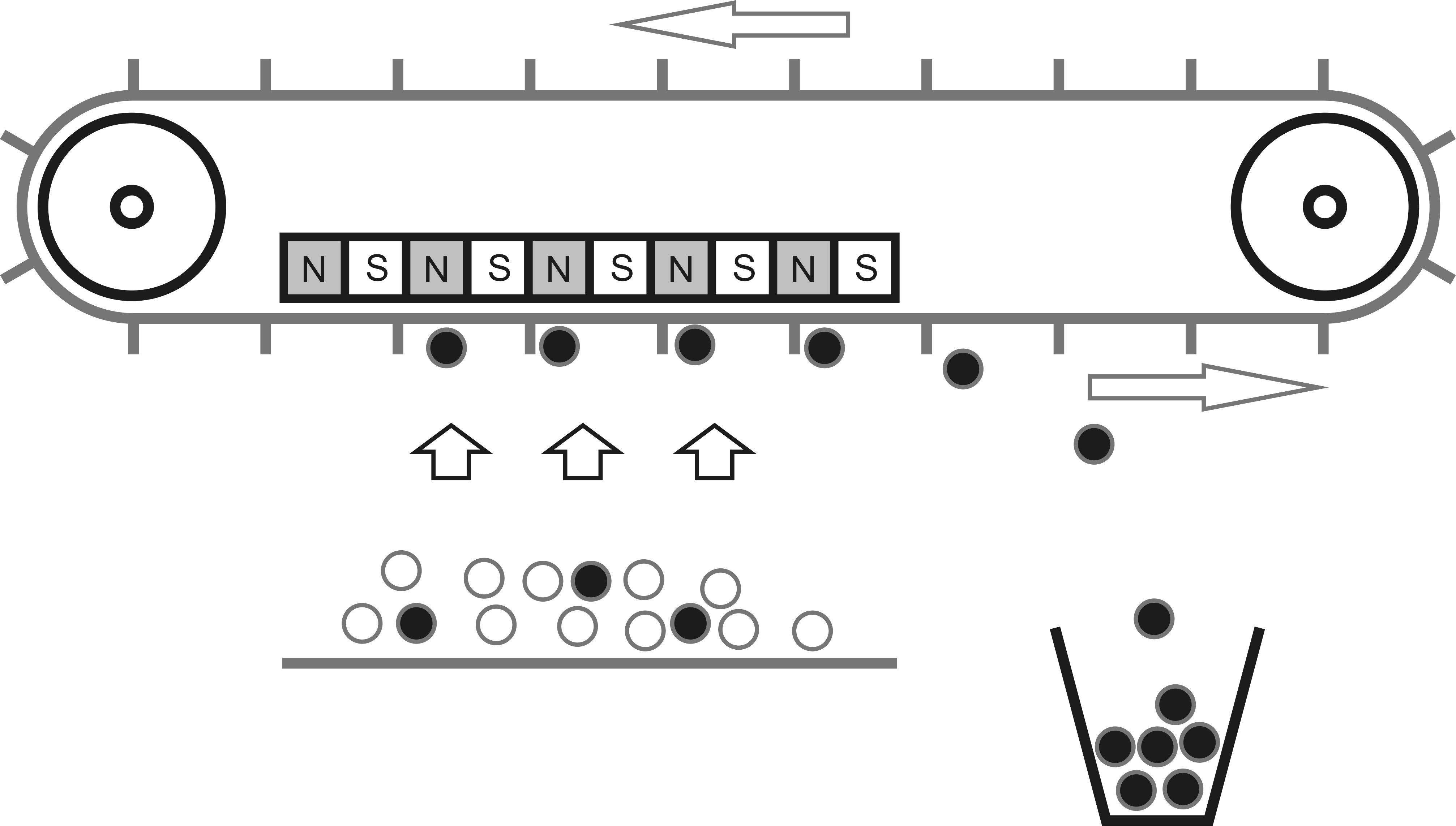

Due to their narrow specialization, drum shredders are the cheapest and most productive option for the mass processing of low boxes and pallets, as well as sheet cuttings from furniture and construction production. Like with a drum chipping machine, the purchase should immediately include spare knives and a sharpening device, and magnetic separation conveniently fits into the ejection conveyor with the installation of a special drive drum, inside which is a system of neodymium magnets. This will reduce the number of aggregates and simplify maintenance. More details on the separation of magnetic impurities can be found in the section on raw material cleaning.

The main technological process in a drum shredder is the breaking of wooden sticks. Therefore, for raw wood that tends to bend instead of break, productivity drops significantly, and processing raw slab wood is not possible at all.

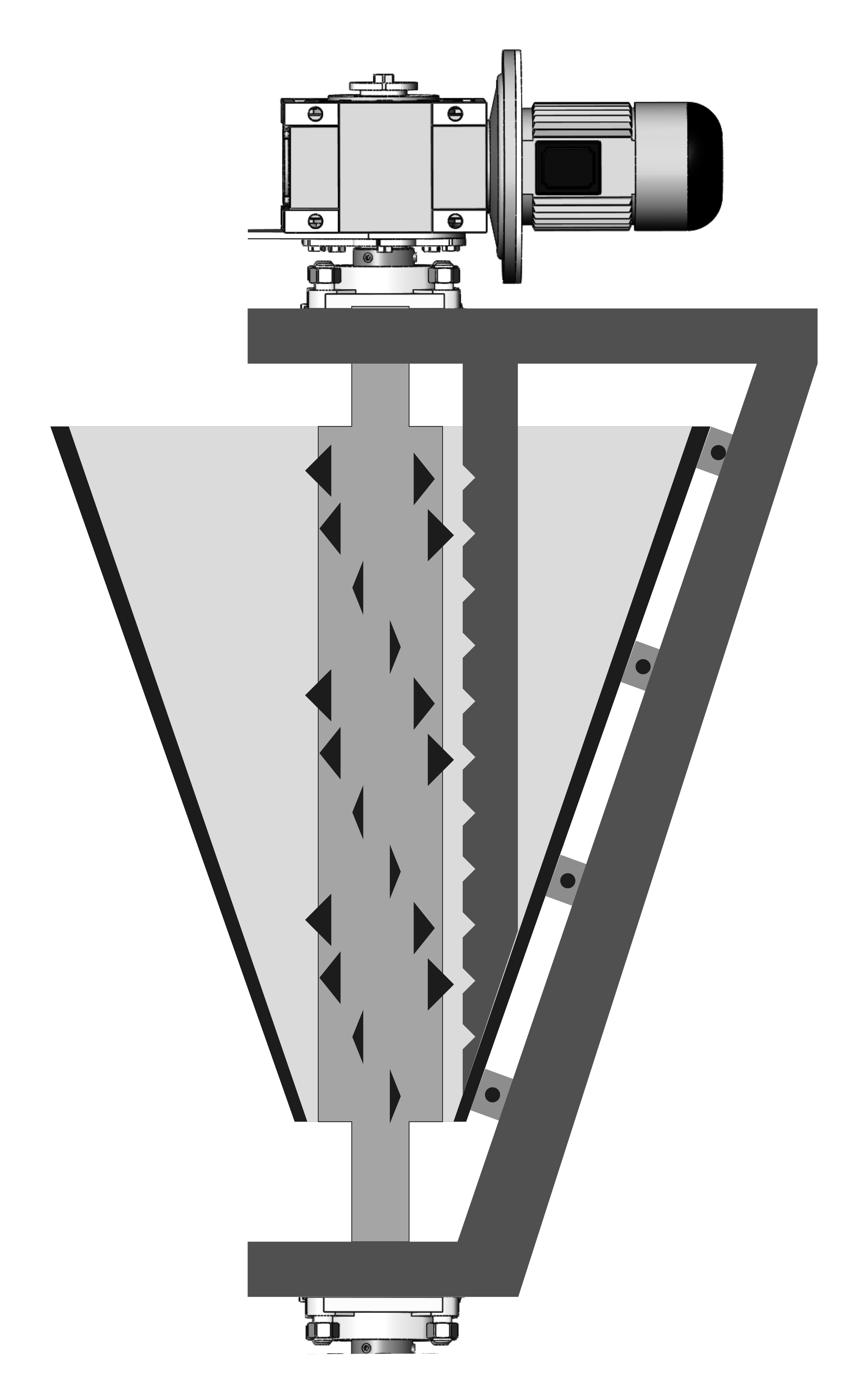

Vertical Shaft Shredder is used when there is a need to shred rather large pieces of wood or other relatively brittle materials at the lowest possible processing speed with minimal drive power and a device that is simple to maintain. The unit consists of a hopper with a central shaft equipped with knives, driven by a low-speed gear motor of 1.5-3 kW (2-4 hp). The upper part of the hopper is wide enough to accommodate logs, stumps, and other similar pieces of wood, while the lower part is narrow enough to prevent oversized chips from passing through the gap between the edge of the hopper and the shaft. On the opposite side from the loading area, there is a stop that prevents unrestricted rotation of pieces within the hopper. As the material is shredded, it moves downward, and the slope of the hopper ensures that it is pressed against the knives by its own weight.

Vertical Shaft Shredder is used when there is a need to shred rather large pieces of wood or other relatively brittle materials at the lowest possible processing speed with minimal drive power and a device that is simple to maintain. The unit consists of a hopper with a central shaft equipped with knives, driven by a low-speed gear motor of 1.5-3 kW (2-4 hp). The upper part of the hopper is wide enough to accommodate logs, stumps, and other similar pieces of wood, while the lower part is narrow enough to prevent oversized chips from passing through the gap between the edge of the hopper and the shaft. On the opposite side from the loading area, there is a stop that prevents unrestricted rotation of pieces within the hopper. As the material is shredded, it moves downward, and the slope of the hopper ensures that it is pressed against the knives by its own weight.

The cheapest option is achieved when using an ordinary water pipe as the shaft, with a chainsaw chain wrapped around it instead of traditional knives, for which several attachments are provided. The teeth do not cut as much as they tear the fibers, producing coarse sawdust or small chips. The profitability of such a device is difficult to predict and it is mostly used domestically. However, nothing stops one from creating a similar shredder with much greater power for industrial use. The advantage lies in the absence of any raw material feeding systems and minimal torque, meaning that instead of a gear motor, a large pulley can be reasonably used to achieve a high-speed shredder of 15 kW (20 hp) or more.