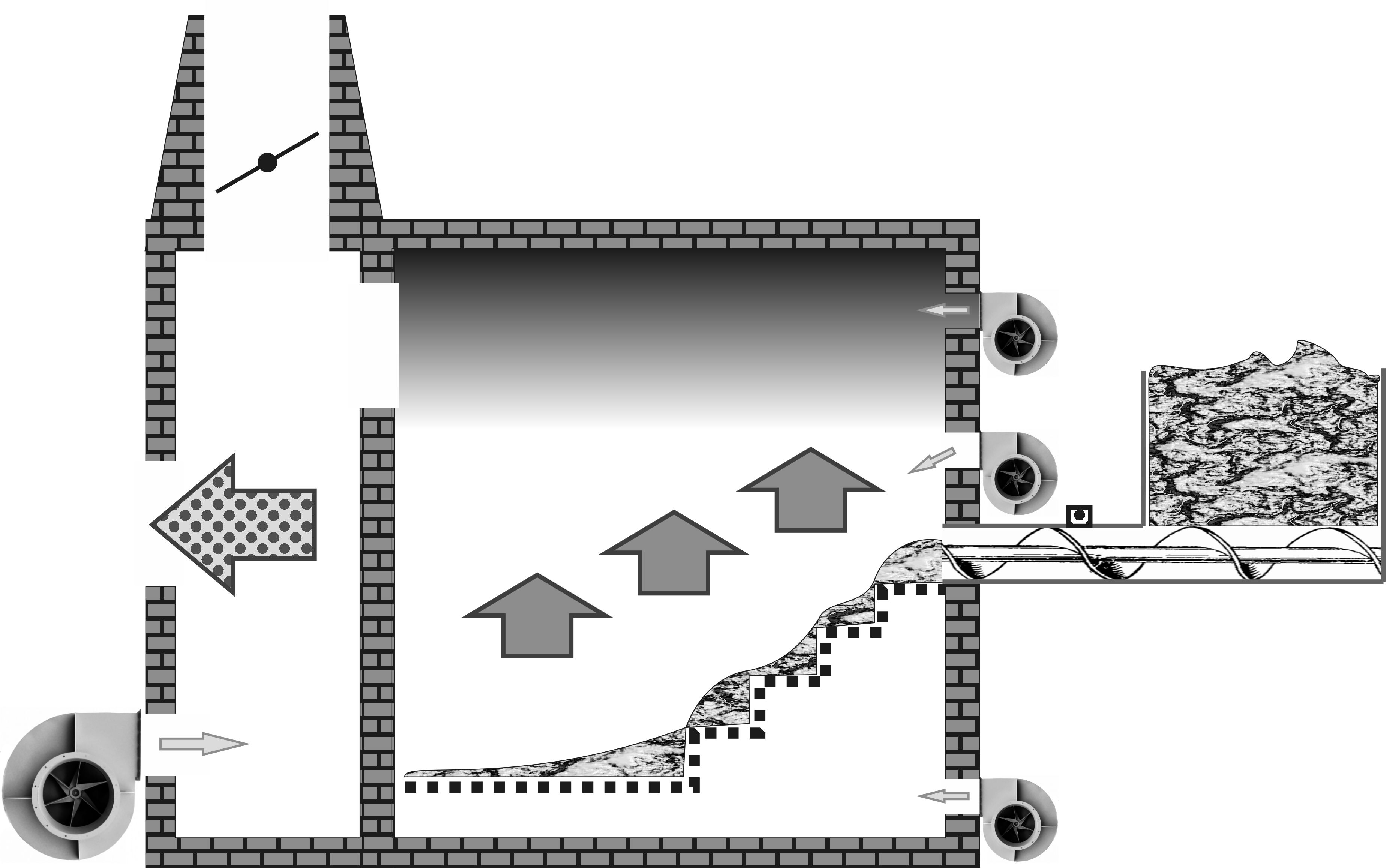

In a stepped heat generator, the grates are arranged in steps, and the top of the furnace is designed as an arch that focuses heat radiation on the fuel, ensuring intense combustion of still half-moist chips. The angle of the stepped surface is usually very close to the natural angle of repose of the fuel, allowing newly added portions to distribute in a fairly thin layer. Fuel cascading down the slope encourages mixing of already ignited chips. Proper distribution of air beneath the grates, above the burning layer, and in the upper part for afterburning makes the process very stable and easy to control. Typically, during the first startup of such a heat generator, besides standard drying and controller testing, the performance parameters of each fan are set for different thermal outputs from 30 to 100% in 5 or 10% increments.

In a stepped heat generator, the grates are arranged in steps, and the top of the furnace is designed as an arch that focuses heat radiation on the fuel, ensuring intense combustion of still half-moist chips. The angle of the stepped surface is usually very close to the natural angle of repose of the fuel, allowing newly added portions to distribute in a fairly thin layer. Fuel cascading down the slope encourages mixing of already ignited chips. Proper distribution of air beneath the grates, above the burning layer, and in the upper part for afterburning makes the process very stable and easy to control. Typically, during the first startup of such a heat generator, besides standard drying and controller testing, the performance parameters of each fan are set for different thermal outputs from 30 to 100% in 5 or 10% increments.

The thin layer of fuel with active air supply promotes good self-cleaning of the grates, allowing stepped grates heat generators to operate nonstop for several years of 24/7 work. For cleaning under the grates, the operation is slowed down to maintain a furnace temperature of about 450-500°C (842-932°F) to avoid damaging the refractory lining. Although an arched roof is not the most reliable option, there are many examples of these heat generators lasting over 10 years without major repairs. Sometimes a screw or chain conveyor is installed under the grates for automatic ash removal, but due to the relative infrequency of this procedure, it is not cost-effective compared to the low labor cost of manual cleaning. A simple and effective option involves embedding a rod from the live floor of the warehouse under the grates with a low-power eccentric drive from a gearbox. A small layer of ash acts as an insulator, and a rod with triangular scrapers withstands high temperatures, and periodic activation allows for inexpensive mechanical ash removal into a designated box.

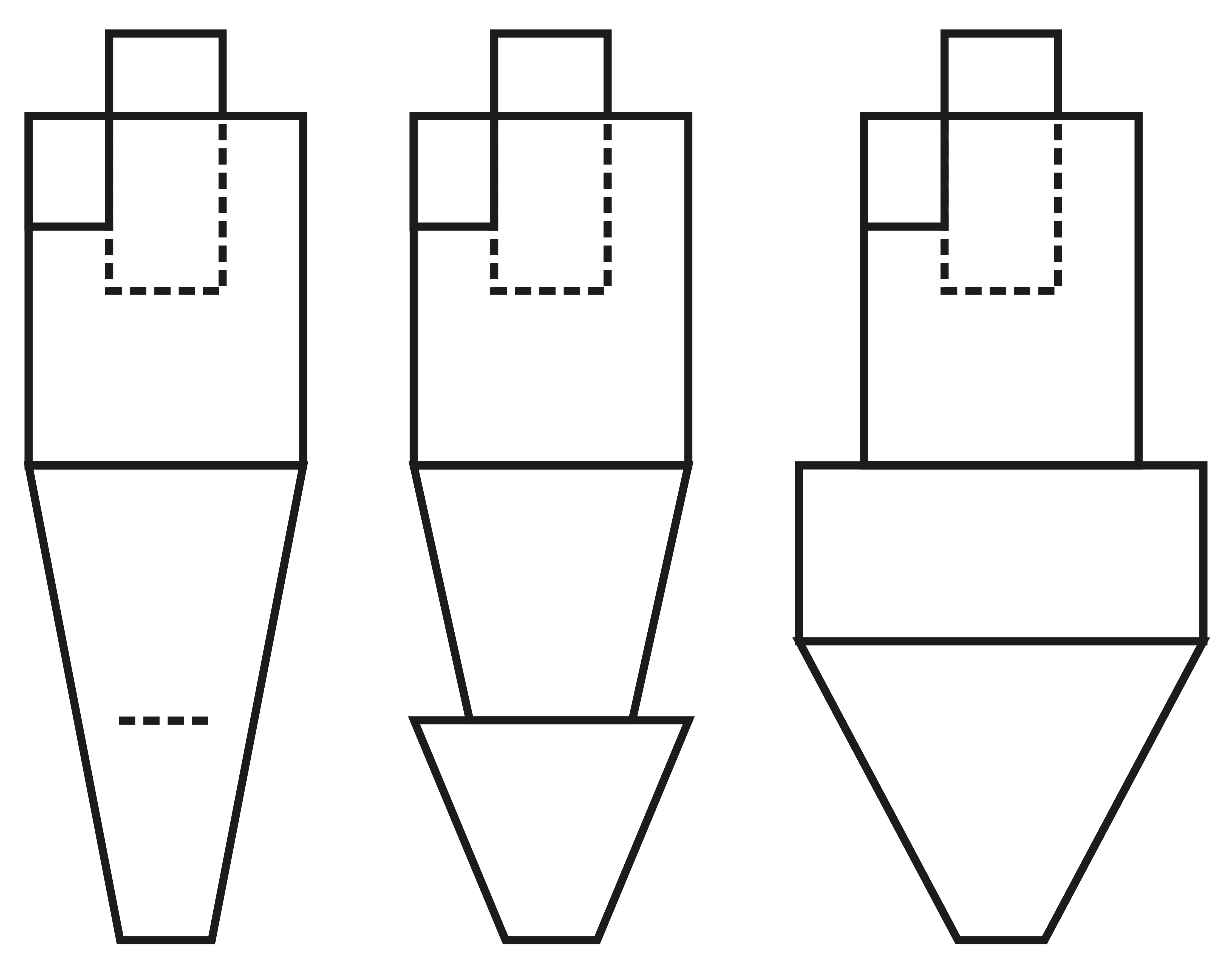

Due to the combustion characteristics, the raw sawdust and small chips contained in the fuel dry and ignite while airborne, so this unit requires a Spark Extinguishing System (SES), which consists of a cyclonic setup made from heat-resistant or stainless steel. The most popular setups are either one large horizontal cyclone with two inlets or a set of vertical cyclones with a common ash collection bin. Since even oxidation-resistant steel serves well only up to 500°C (932°F), the mixture is prepared inside the heat generator in a special mixing chamber equipped with automatic louvers and a fairly powerful supply fan. Considering that there must be constant underpressure in the furnace to prevent carbon monoxide from leaking out, installing a blower fan is not very clear and is justified mainly by tradition, as an atavism from other applications of the heat generator. Typically, an exhaust fan with large capacity is installed at the dryer outlet, pulling air and gases through the entire tract from the heat generator's intake under the grates to the dryer's cyclone. In principle, keeping the mixing entry relatively free with slightly closed louvers ensures stable minimal underpressure to avoid excessive air supply through fans, which also act more as flow locks than blowers. Thus, the temperature of the thermal agent will be regulated solely by fuel supply and adjusting airflow for its effective combustion.

The startup pipe, having a fairly large diameter and a lined lower part, creates strong draft. Therefore, when switching to emergency mode by opening the damper, all pyrolysis gases and heat exit the workshop, ensuring the dryer's safety. During operation, the damper nearly completely closes the pipe to prevent incoming cold air from creating excessive pressure that could break through dangerous gases into the room.

The disadvantages of a heat generator with staged grates include the complexity of transporting and assembling the furnace, which consists of several multi-ton blocks. The vaulted surface is much less tolerant of repeated starts and is difficult to restore. The ambiguity in behavior under different thermal agent consumption levels presents challenges in tuning and maintaining a stable level of rarefaction in the furnace. Safe manual control or primitive automation is practically unachievable.

The design features imply only the top feed method for fuel, causing issues with ignition in the auger or its overheating. Installing hydraulic pushers instead of an auger partially addresses the problem, but maintenance of the hydraulics in changing temperature conditions is required, and too large fuel pieces still create blockages and can damage the entry to the furnace chamber.

The advantages include much greater safety compared to the pyrolytic version and the ability to work with a wide range of moisture content and particle size of the raw fuel. It's important to consider that for fine sawdust, grates with much larger and wider openings are necessary to prevent small "fountains" from causing general particle suspension and a volumetric explosion. Continuous operation allows staged grates to be used as boilers, where instead of the upper arch, a block with heat exchangers is installed.

The thermal power of the heat generator can be roughly estimated by the working area of the grates, referred to as the "burning mirror," and the volume of the furnace in the active combustion zone. For every megawatt of heat from raw wood, at least 1.5 square meters (16 square feet) of grates and at least 3 cubic meters (100 cubic feet) of internal space are required.