In another case, a dryer based on the AVM-0.65 drum with a wood-fired heat generator equipped with basic automation achieved productivity of 1500 kg per hour. This is significantly higher than the typical 700-1000 kg per hour for wooden materials at most similar productions. The initial material is fine sawdust with a moisture content of 50-55%.

In another case, a dryer based on the AVM-0.65 drum with a wood-fired heat generator equipped with basic automation achieved productivity of 1500 kg per hour. This is significantly higher than the typical 700-1000 kg per hour for wooden materials at most similar productions. The initial material is fine sawdust with a moisture content of 50-55%.

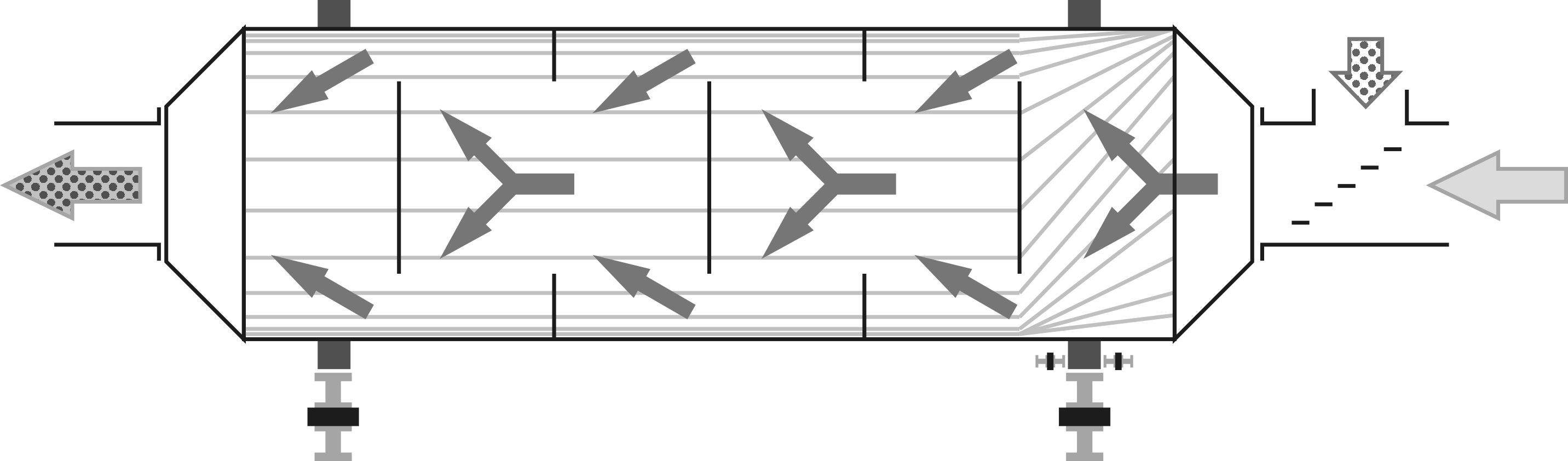

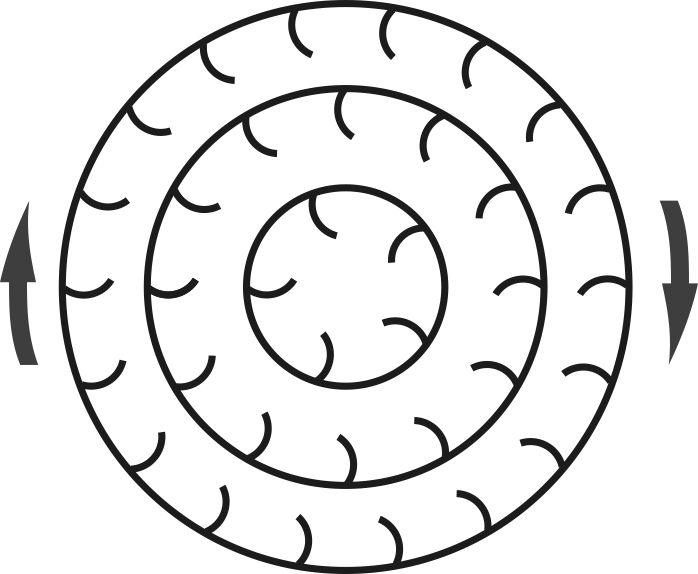

By gradually decreasing the rotation speed and adjusting the flow rate and temperature of the heat agent, maximum productivity was achieved at 1 RPM. The only way to explain this phenomenon is the triple-pass design of the dryer, which consists of three drums nested inside each other like a matryoshka doll. The relatively thick walls of these drums participated in heat transfer as additional fittings. Hence, even a quarter turn exposed part of the wall and shifted the sawdust onto the adjacent hot surface. Such a low rotation speed significantly reduced floating, allowing much more material to be pushed through for simultaneous drying.

By gradually decreasing the rotation speed and adjusting the flow rate and temperature of the heat agent, maximum productivity was achieved at 1 RPM. The only way to explain this phenomenon is the triple-pass design of the dryer, which consists of three drums nested inside each other like a matryoshka doll. The relatively thick walls of these drums participated in heat transfer as additional fittings. Hence, even a quarter turn exposed part of the wall and shifted the sawdust onto the adjacent hot surface. Such a low rotation speed significantly reduced floating, allowing much more material to be pushed through for simultaneous drying.

It should be noted that the operating temperatures of all three passes vary greatly, and during heating, the length of the inner drums increases significantly. Therefore, the stages are rigidly fixed at only one end, and the other end rests on the outer shell via special slides. These ensure solid radial centering and relatively free longitudinal movement. The issue of thermal expansion renders unfeasible a seemingly obvious design where all three cylinders are joined by radial walls. Although it appears strong at first glance, such a welded construction can tear and warp after the first start.

It should be noted that the operating temperatures of all three passes vary greatly, and during heating, the length of the inner drums increases significantly. Therefore, the stages are rigidly fixed at only one end, and the other end rests on the outer shell via special slides. These ensure solid radial centering and relatively free longitudinal movement. The issue of thermal expansion renders unfeasible a seemingly obvious design where all three cylinders are joined by radial walls. Although it appears strong at first glance, such a welded construction can tear and warp after the first start.

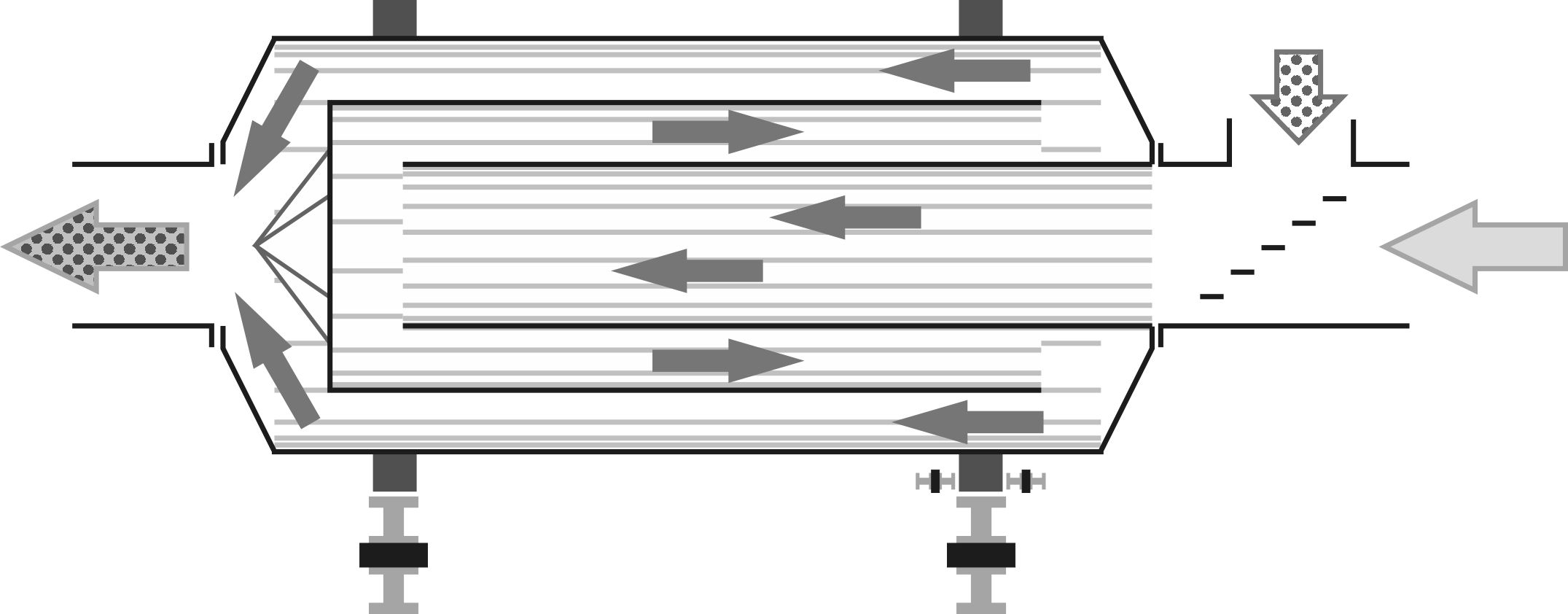

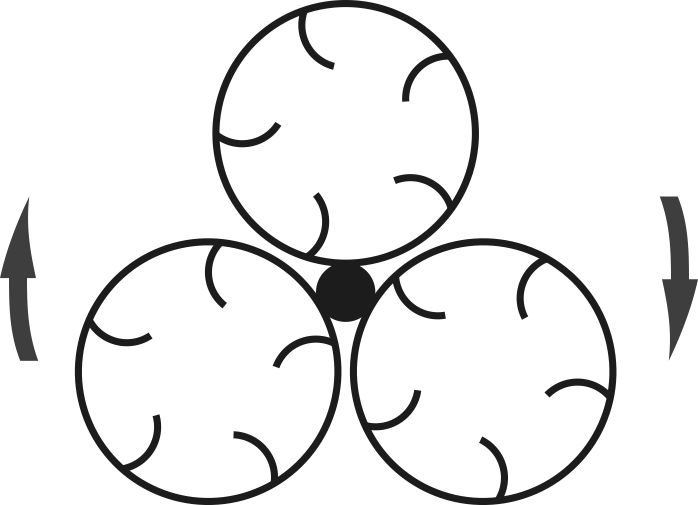

Another exotic design of a triple-pass drum involves mounting three separate 1-meter diameter drums on a single shaft. This design favors noticeable savings in casing manufacturing by utilizing standard steel pipes but complicates interconnection with air ducts and demands high precision in manufacturing the main shaft and its bearing supports. The drive mechanism for such a construction and its external thermal insulation are another story altogether...

Another exotic design of a triple-pass drum involves mounting three separate 1-meter diameter drums on a single shaft. This design favors noticeable savings in casing manufacturing by utilizing standard steel pipes but complicates interconnection with air ducts and demands high precision in manufacturing the main shaft and its bearing supports. The drive mechanism for such a construction and its external thermal insulation are another story altogether...

In summary, a single-pass drum has a diameter limit of around two meters, beyond which efficiency decreases regardless of the complexity of the fittings. A four- or six-blade fitting in the center is sufficient for holding sawdust and increasing efficiency. Arranging complex fittings in multiple circumferences at varying diameters can boost efficiency by 10-15%, but greatly complicates the design and increases costs. The diameter limitation is partially offset by the triple-pass solution, introducing the problem of warping and maintenance difficulty. For any drum, there is a limit to the length-to-diameter ratio that maintains strength, akin to calculating a truss on two support points. For excessively long drums, another problem arises: the mutual positioning of support stations and shifts on wheels due to thermal expansion. As a result, most classical drum dryers are manufactured with a productivity range of 1 to 3 tons per hour. Further increases in geometric size lead to disproportionate cost increases and significant challenges in transportation to the installation site.

In summary, a single-pass drum has a diameter limit of around two meters, beyond which efficiency decreases regardless of the complexity of the fittings. A four- or six-blade fitting in the center is sufficient for holding sawdust and increasing efficiency. Arranging complex fittings in multiple circumferences at varying diameters can boost efficiency by 10-15%, but greatly complicates the design and increases costs. The diameter limitation is partially offset by the triple-pass solution, introducing the problem of warping and maintenance difficulty. For any drum, there is a limit to the length-to-diameter ratio that maintains strength, akin to calculating a truss on two support points. For excessively long drums, another problem arises: the mutual positioning of support stations and shifts on wheels due to thermal expansion. As a result, most classical drum dryers are manufactured with a productivity range of 1 to 3 tons per hour. Further increases in geometric size lead to disproportionate cost increases and significant challenges in transportation to the installation site.