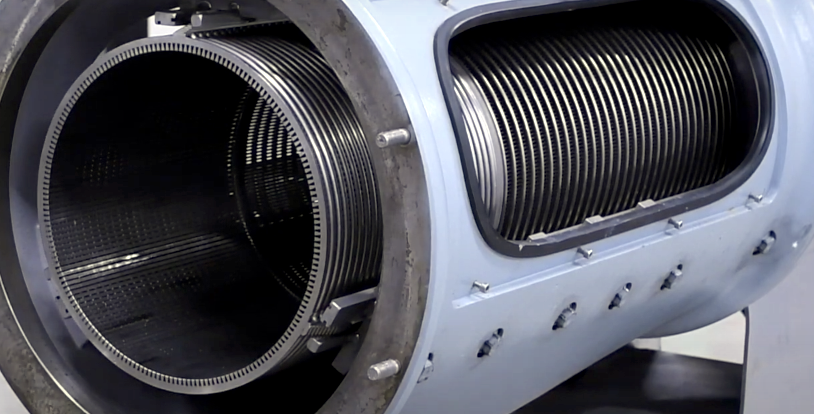

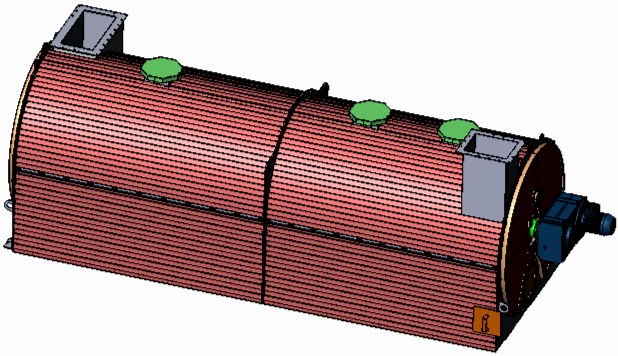

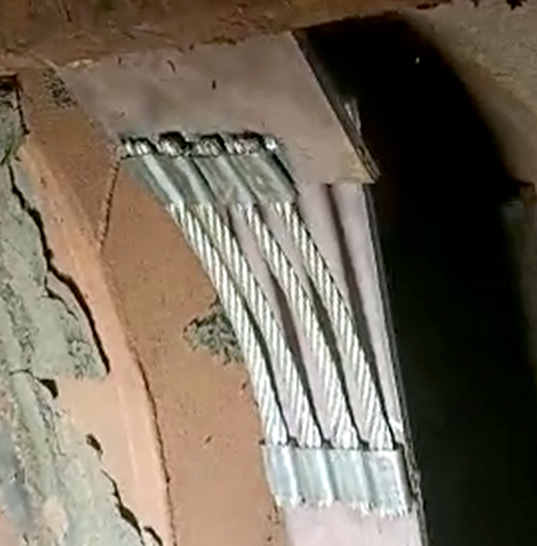

The third variant of a dryer with a stationary cylindrical body and rotor is the vacuum dryer, mainly used for drying manure and other sticky types of raw materials whose drying process releases caustic and hazardous gases. These dryers typically have a small diameter, and the scrapers are attached to the rotor shaft through a compressed stainless steel cable, acting as a spring. The spring-loaded scrapers continuously clean adhered material from the body and apply fresh portions. Heat is supplied through the body, therefore the volume of the resulting vapor-gas mixture is significantly less than when directly blowing material with a thermal agent. Vortex vacuum pumps connected to the dryer reduce the internal pressure by 30-50 kPa (4-7 psi), lowering the boiling point of moisture. As a result, heat exchange processes in the dryer occur more effectively, and the gentle heating preserves the biological value of the material as fertilizer.

The third variant of a dryer with a stationary cylindrical body and rotor is the vacuum dryer, mainly used for drying manure and other sticky types of raw materials whose drying process releases caustic and hazardous gases. These dryers typically have a small diameter, and the scrapers are attached to the rotor shaft through a compressed stainless steel cable, acting as a spring. The spring-loaded scrapers continuously clean adhered material from the body and apply fresh portions. Heat is supplied through the body, therefore the volume of the resulting vapor-gas mixture is significantly less than when directly blowing material with a thermal agent. Vortex vacuum pumps connected to the dryer reduce the internal pressure by 30-50 kPa (4-7 psi), lowering the boiling point of moisture. As a result, heat exchange processes in the dryer occur more effectively, and the gentle heating preserves the biological value of the material as fertilizer.

The gases removed from the dryer, containing hazardous amines and mercaptans, are fed into the heat generator for co-combustion with fuel. This unique solution completely eliminates unpleasant odors from the production site and surrounding areas when processing raw materials that are hazardous waste from poultry farms.

Despite the undeniable advantages in drying paste-like materials and disposing of hazardous gases, vacuum dryers are more sensitive to the homogeneity of raw material composition and the presence of foreign objects. For continuous operation, precise dosing equipment is required, which can jam or be damaged by large stones or sticks. Operating with periodic loading and unloading reduces the average daily productivity by 2-3 times, which translates, in financial terms, to a corresponding increase in capital expenses to maintain the same monthly output rates.