Separating bulk materials into fractions through sieves is one of the oldest methods, still relevant today. The design of all vibrating screens is based on standard vibratory conveyors that use vibrators and eccentric shafts, which were discussed in the raw material transportation section. In the pellet industry, sieving with screens is used to clean raw materials and separate dust from the finished product.

If the factory does not use a debarking machine and bark beetles are prohibited from existence, or if logs are delivered to the pellet plant still with bark without the possibility to remove it, vibrating sieves can eliminate foreign contaminants by producing a darker pellet still suitable for most household boilers due to its ash content. After chopping wood chips with bark to a fraction of needles and crumbs and subsequent drying, sand is separated from wood particles. In the forest, wind transports sand and dust of up to 0.6-0.8 mm (0.02-0.03 inches) in size, and the main fraction of wood after drying ranges from 5 to 20 mm (0.2-0.8 inches). Thus, by using a sieve with holes of 0.8-1.2 mm (0.03-0.05 inches), over 90% of foreign mineral inclusions can be removed. This not only enhances pellet quality but also significantly reduces wear on consumables in hammer mills and pellet mills. Stainless steel sieves with a thickness of 0.8-1 mm (0.03-0.04 inches) perform well, with the cell diameter determined by the ash content analysis, which is 15-25%. A sand separator is installed immediately after the dryer before the hammer mill for dry raw materials, i.e., before final grinding. The siftings can be used for mulching certain agricultural crops or in construction mixtures, where relatively large fractions of wood flour and sand are applied.

If the factory does not use a debarking machine and bark beetles are prohibited from existence, or if logs are delivered to the pellet plant still with bark without the possibility to remove it, vibrating sieves can eliminate foreign contaminants by producing a darker pellet still suitable for most household boilers due to its ash content. After chopping wood chips with bark to a fraction of needles and crumbs and subsequent drying, sand is separated from wood particles. In the forest, wind transports sand and dust of up to 0.6-0.8 mm (0.02-0.03 inches) in size, and the main fraction of wood after drying ranges from 5 to 20 mm (0.2-0.8 inches). Thus, by using a sieve with holes of 0.8-1.2 mm (0.03-0.05 inches), over 90% of foreign mineral inclusions can be removed. This not only enhances pellet quality but also significantly reduces wear on consumables in hammer mills and pellet mills. Stainless steel sieves with a thickness of 0.8-1 mm (0.03-0.04 inches) perform well, with the cell diameter determined by the ash content analysis, which is 15-25%. A sand separator is installed immediately after the dryer before the hammer mill for dry raw materials, i.e., before final grinding. The siftings can be used for mulching certain agricultural crops or in construction mixtures, where relatively large fractions of wood flour and sand are applied.

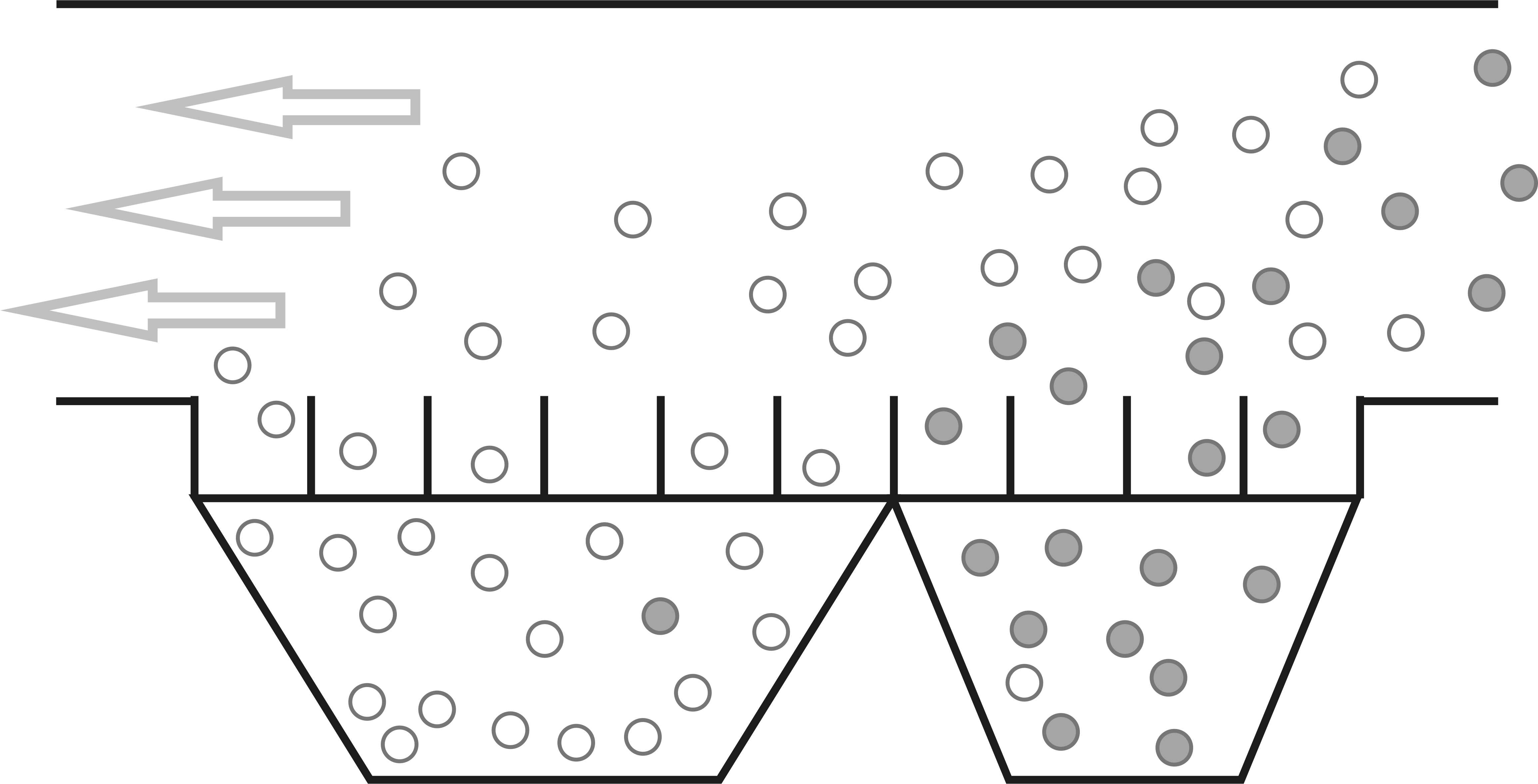

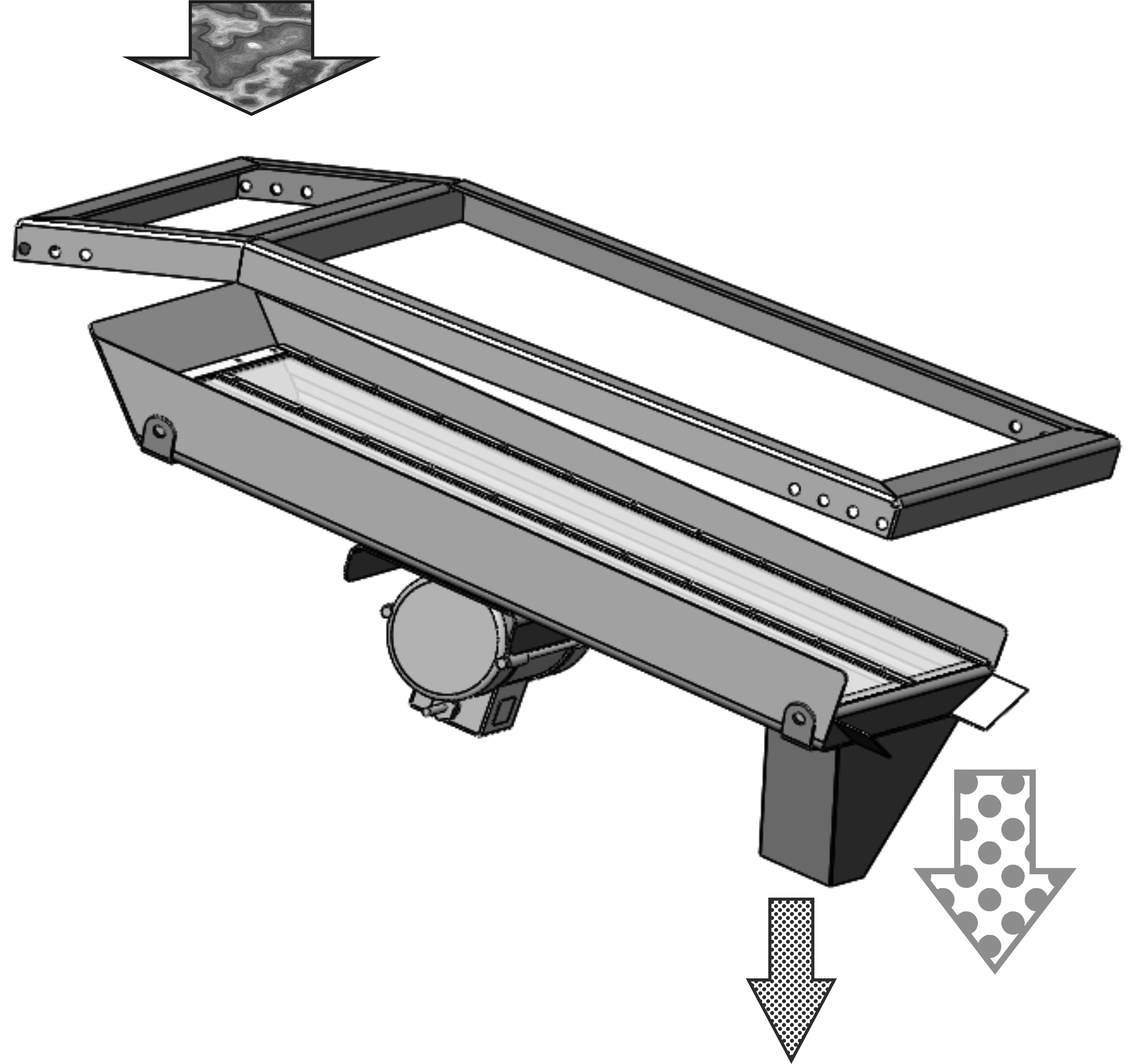

The same vibrating sieve is used for separating siftings and breaking crumbs away from pellets, but with a sieve having cell size 1 mm (0.04 inches) less than the pellet diameter. The same type of sieve can be used to clean dry sawdust from stones and bark pieces that pass through the dryer with the main raw material. Many developers do not favor using vibrators for classifying organic materials because they tend to clog the cells and require regular cleaning. Eccentric shaft movements promote self-cleaning, although they complicate construction. For a particle to clog, it must touch three points at the edges of the hole and stop moving from the impact of vibration and incoming material. Therefore, using square mesh sieves sharply reduces clogging and promotes self-cleaning even when using inexpensive industrial vibrators.

To separate fractions, vibrating raw materials must pass over at least 500 mm (20 inches) of the sieve with a layer no more than 15-20 mm (0.6-0.8 inches), taking about 2 seconds at an incline of approximately 20°. From these practical figures, it is generally possible to design a sieve for any capacity, but at a capacity of 5-7 tonnes per hour, special attention must be paid to material distribution across the entire width of the sieve.

A 1 mm (0.04 inches) thick sieve provides the maximum perforation percentage, but the material forces too thin a mesh to vibrate synchronously, reducing work efficiency. To avoid this, longitudinal supports for the mesh should be provided at intervals of 200-250 mm (8-10 inches) or choose a thicker sieve and more powerful vibrator.