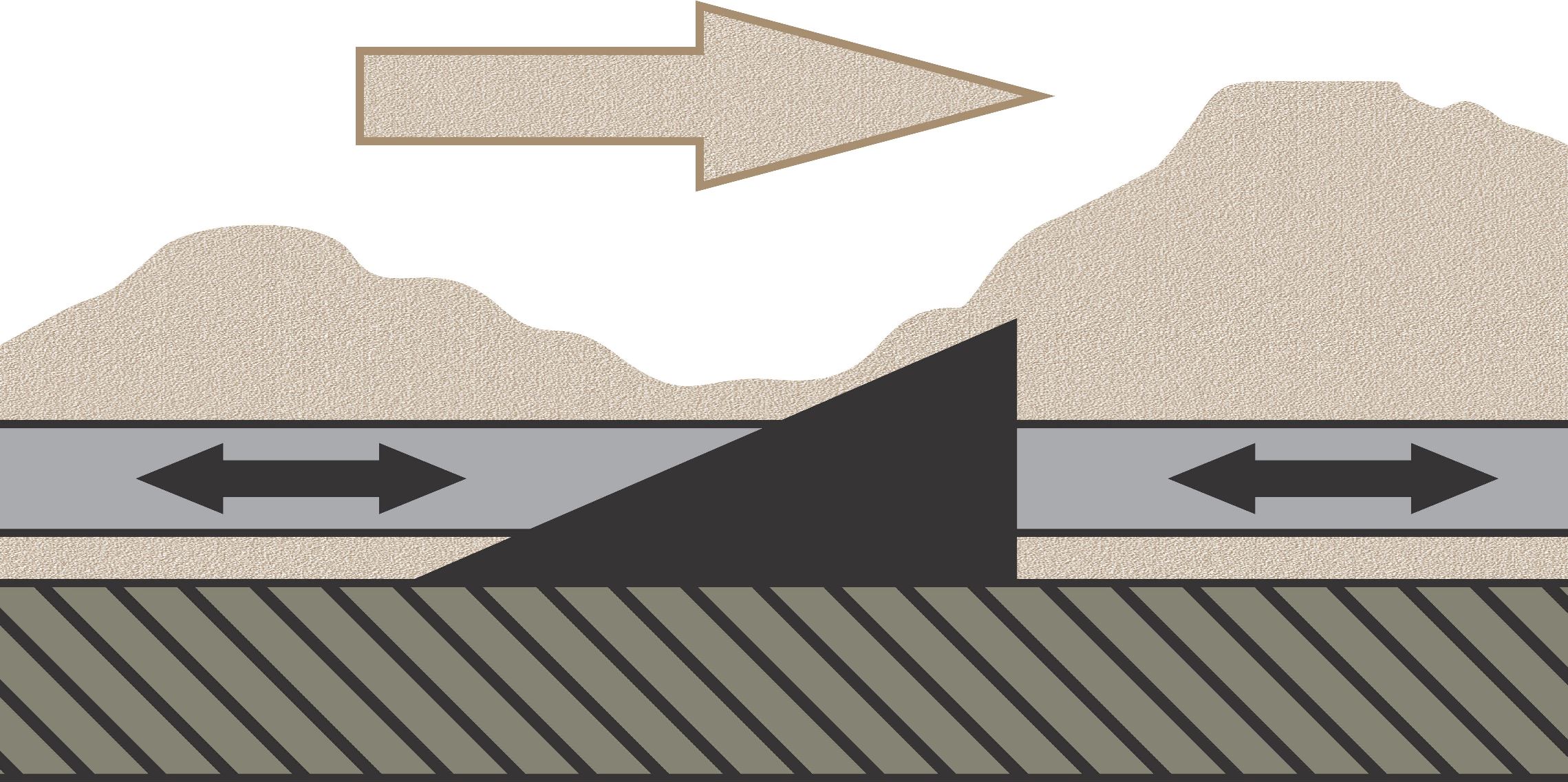

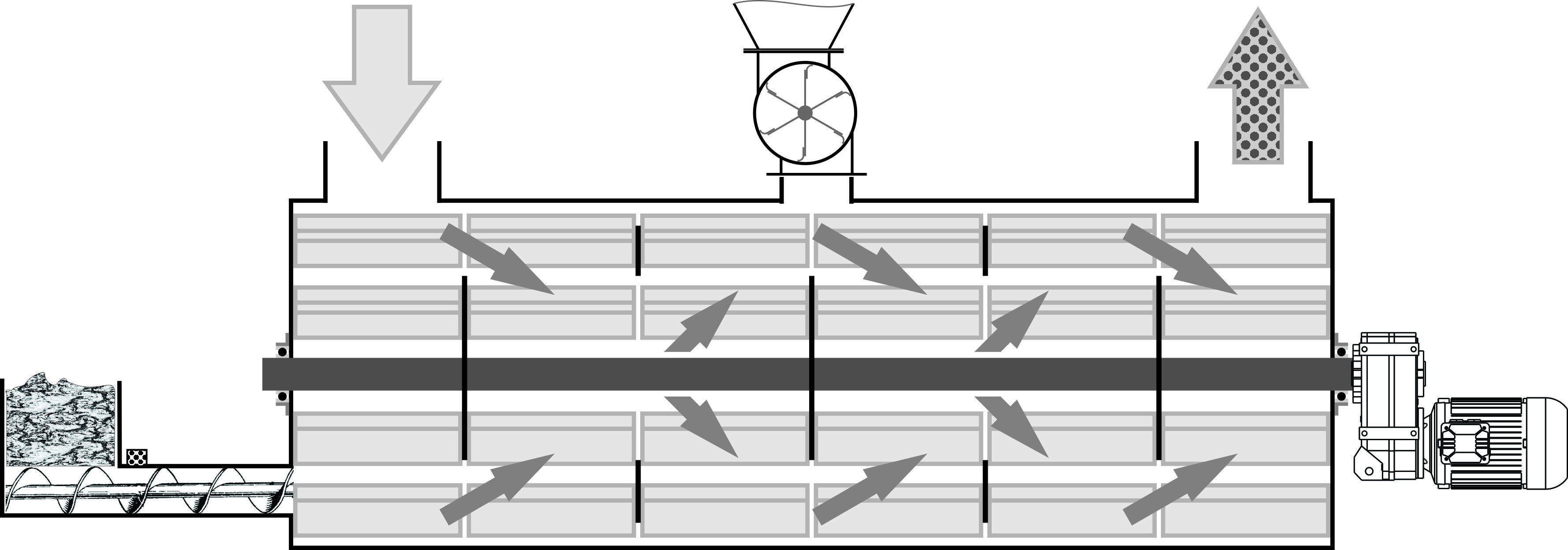

An interesting engineering solution for large storage volumes with mechanized unloading is a warehouse with an overhead conveyor. In this setup, there is no excessive load from the raw material mass on the chains and scrapers. The height of the conveyor is adjusted using cable winches, and horizontal displacement is prevented by rollers installed at the corners, which rest on vertical rails fixed to the walls. Due to the minimal load, the size of such a conveyor is generally unrestricted, as its frame can be made from girders, allowing it to exceed 6 meters (20 feet) in width. Typically, such a warehouse is divided into sections of 3 or 6 meters (10 or 20 feet) and unloaded sequentially, which helps more predictably and evenly fill the output conveyor that runs along all the exits. To monitor the filling level of the output conveyor, a level sensor is installed directly above it, which also helps automate the winches.

An interesting engineering solution for large storage volumes with mechanized unloading is a warehouse with an overhead conveyor. In this setup, there is no excessive load from the raw material mass on the chains and scrapers. The height of the conveyor is adjusted using cable winches, and horizontal displacement is prevented by rollers installed at the corners, which rest on vertical rails fixed to the walls. Due to the minimal load, the size of such a conveyor is generally unrestricted, as its frame can be made from girders, allowing it to exceed 6 meters (20 feet) in width. Typically, such a warehouse is divided into sections of 3 or 6 meters (10 or 20 feet) and unloaded sequentially, which helps more predictably and evenly fill the output conveyor that runs along all the exits. To monitor the filling level of the output conveyor, a level sensor is installed directly above it, which also helps automate the winches.

To ensure smooth layer removal of raw material, the teeth on the scrapers are not uniformly placed. On each subsequent scraper, the protrusion is offset by approximately the width of a tooth. You can also notice that the lower edge of the horizontal part of the scraper is level with the chain. This greatly reduces tilting stresses on the scraper and eliminates excessive chain tension during operation.

An additional advantage of such a warehouse is that wheeled machinery can enter it, which only requires covering the output conveyor with small platforms. Maintenance and repair are also much simpler since in case of sudden breakdown, it can be cleared with a front loader, and the absence of hydraulics places much lower demands on personnel qualifications.

The storage volume of one section, with a width of 6 meters (20 feet) and a length of 12 meters (40 feet), can be up to 500-700 m3 (130,000-180,000 gallons) with sufficiently strong walls of 8-10 meters (26-33 feet) in height.