Brief Answer: The Pellet Durability Index (PDI) significantly increases with the addition of starch and various types of food flours.

Problem Symptoms

Main Causes

- Hardwood species have low lignin content and even with correct pelleting parameters, particles do not bond together.

- Too fine raw material fraction means wood flour does not heat adequately in the die.

- High mineral content because mineral particles hinder the bonding of organic material.

Problem Solution

- Add about 1% starch before pelleting birch raw material. The allowable starch content is no more than 1.8%.

- Use a screen with larger mesh in the hammer mill to reduce the share of wood dust in the raw material before pelleting.

- Add 3-4% starch when pelleting sanding dust using a longer working channel length on the die.

- Clean the wood raw material from mineral impurities to reduce starch consumption.

How to Avoid Repeating the Issue

Monitor the cleanliness of the raw material and the species of wood being processed. For overly fine materials, use a die with a greater effective length of holes.

Expert Advice

To reduce costs, choose the cheapest available starch type in your area: corn, potato, or rice. The consumption is practically the same. Additionally, various types of food flours can be used in similar quantities as stated for starch. Often in woodworking factories, wood glue is used, made from rye flour. Use this for combining ordering consumables, which will simplify logistics and help get discounts from suppliers.

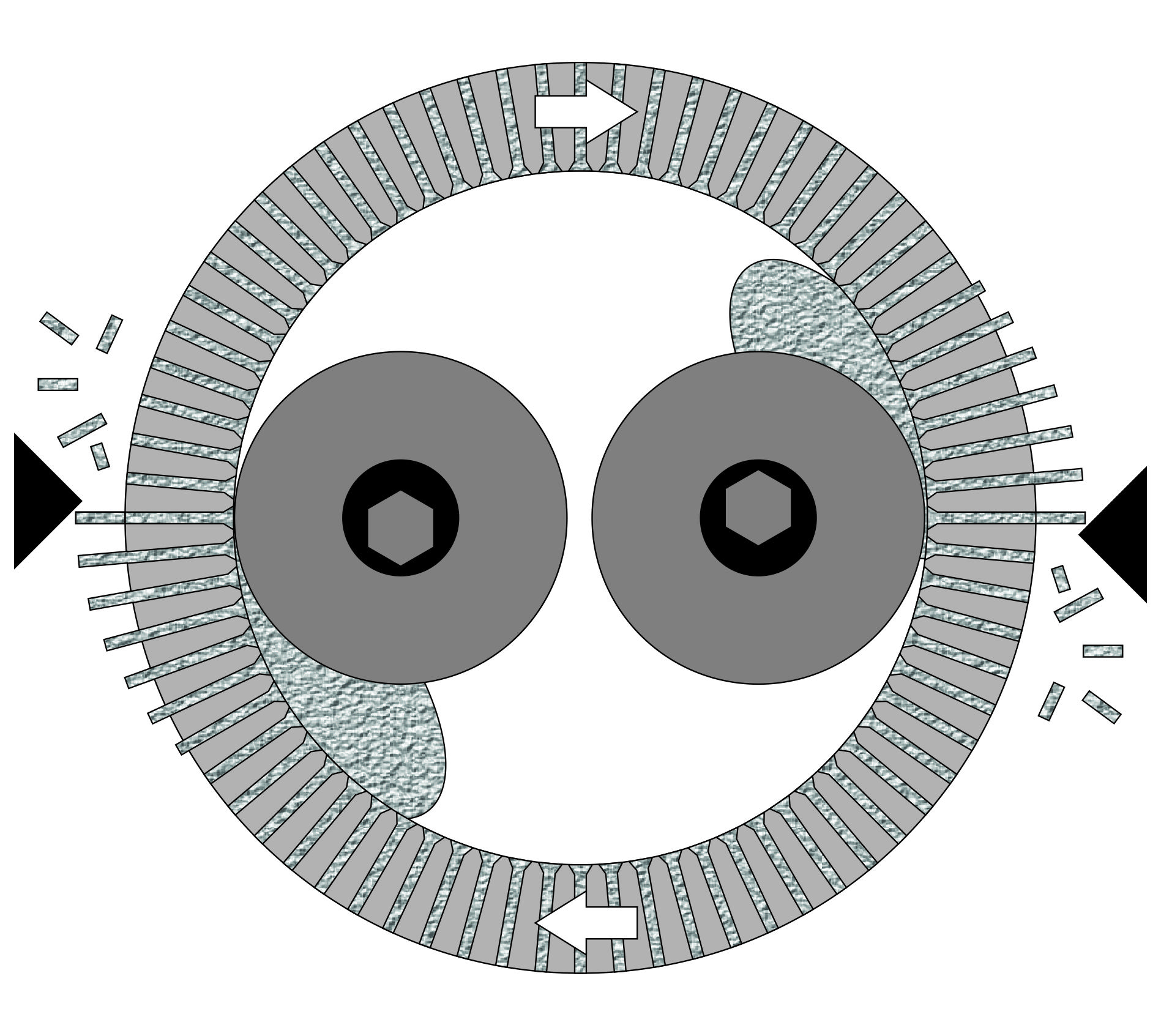

Sanding dust or wood flour possesses high flowability and low thermal conductivity, which hinders heating and bonding. Small particles quickly polish the die holes to a mirror state, and the reducing friction worsens the situation. If adding starch is permissible, increase the effective hole length to produce dense pellets. However, if starch addition is not allowed and pellets are used as raw materials for chemical production, consider increasing the track width of the die to slow the passage of raw material and increase dwell time. More details on the pelleting process can be found in the article "Fundamentals of the Pelletizing Process".

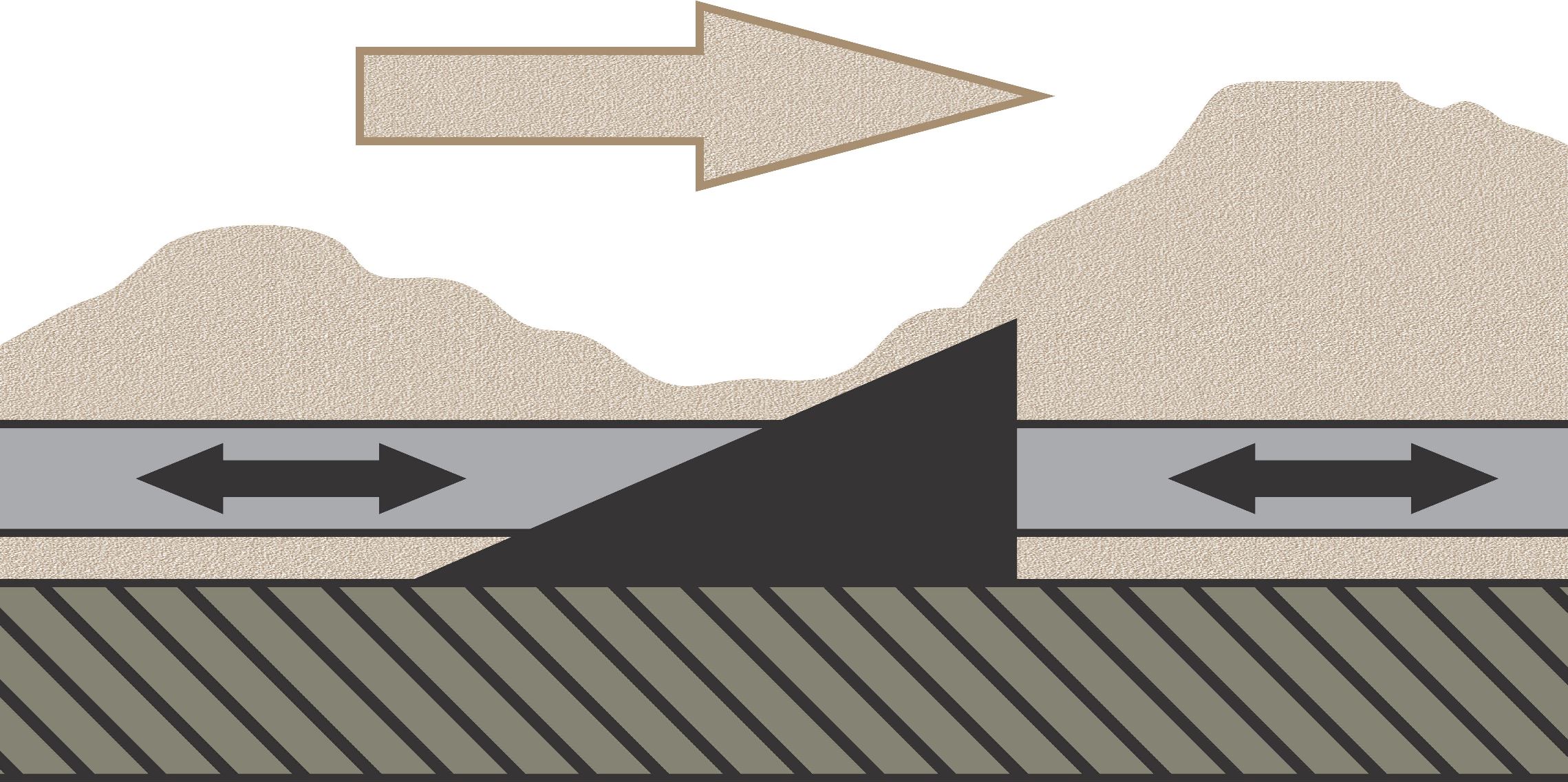

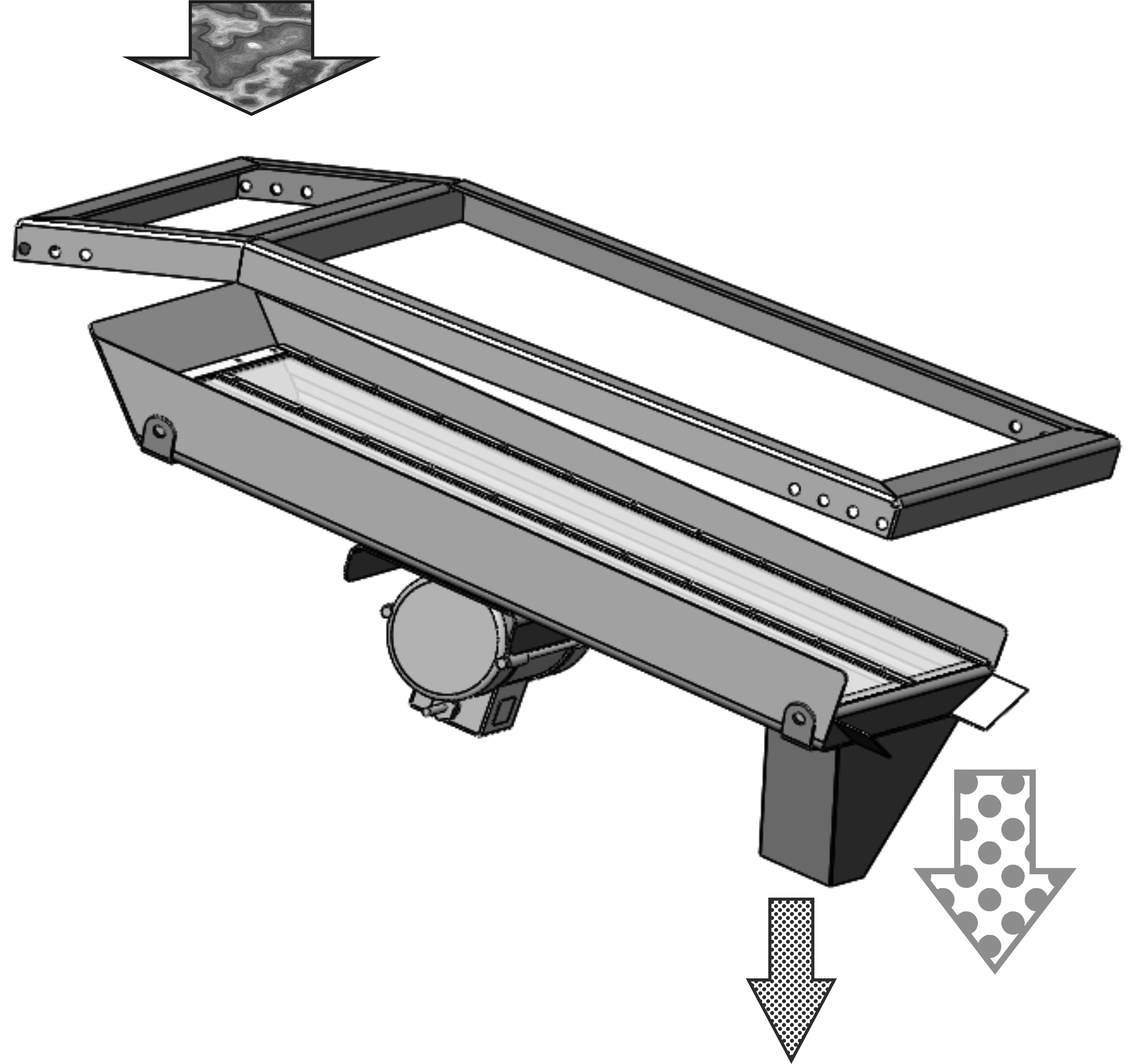

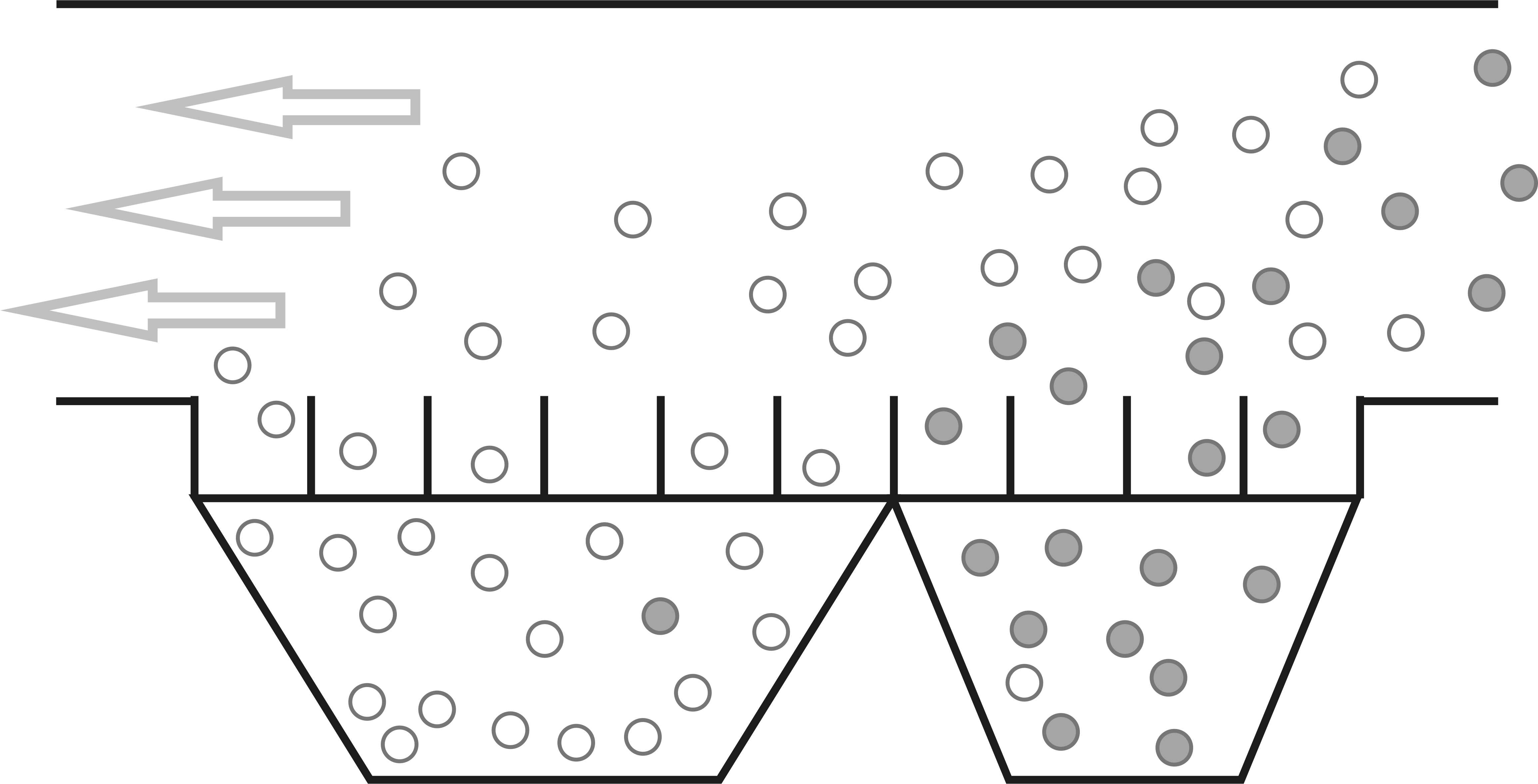

Wood raw material contamination with sand often occurs when processing wood with bark. If debarkers cannot be installed, use a sifter to separate fractions after drying and before the hammer mill. When processing chips, they remove the smallest impurities along with sand. When processing sawdust, they separate larger impurities, removing bark pieces and stones. This process is described in detail in the article "Vibrating Screens and Sifters".