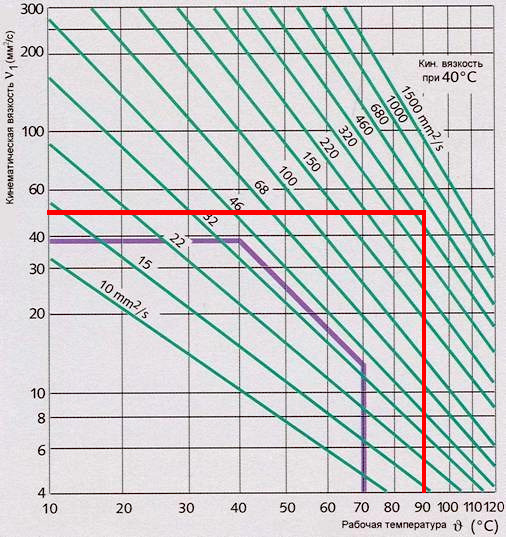

Quick Answer: The optimal moisture content of the raw material is 8-12% depending on the pellet mill and type of raw material.

Problem Symptoms

Main Causes

- Fatty material — fat acts as a natural lubricant and facilitates the passage of the material through the holes without compacting.

- Significant moisture fluctuations — wood and other hard-to-pelletize materials react sharply to minimal changes in moisture.

- Sand and other mineral impurities — sand particles create increased friction in the die holes and cause the raw material to overheat.

Problem Solution

- Measure the moisture content of the raw material at the moment when you achieve high-quality pellets with high productivity and ensure that moisture deviation does not exceed 0.5% in any direction.

- Use a sensor for instant determination of pellet hardness at the exit from the pellet mill door.

- Check the feed formulation and reduce moisture to 5-7% when high in fat.

- For high ash content, add water to increase moisture to 15-25% proportional to the mineral content.

How to Prevent Recurrence

Determine the optimal moisture for pelletizing through experience by assessing pellet quality and stabilize this parameter. Add fat through spraying and soaking after feed pelletizing. Provide more water for moisture if the raw material is high in ash.

Expert Tips

Typically, the moisture content of the raw material before the pellet mill is 2-5% higher than the final pellet. Knowing the target moisture of the pellet narrows down the range for finding the optimal raw material moisture levels. A slight excess of moisture is necessary for nearly any material, as it aids in uniform distribution between particles and bonding. Read more in the article "Fundamentals of the Pelletizing Process"

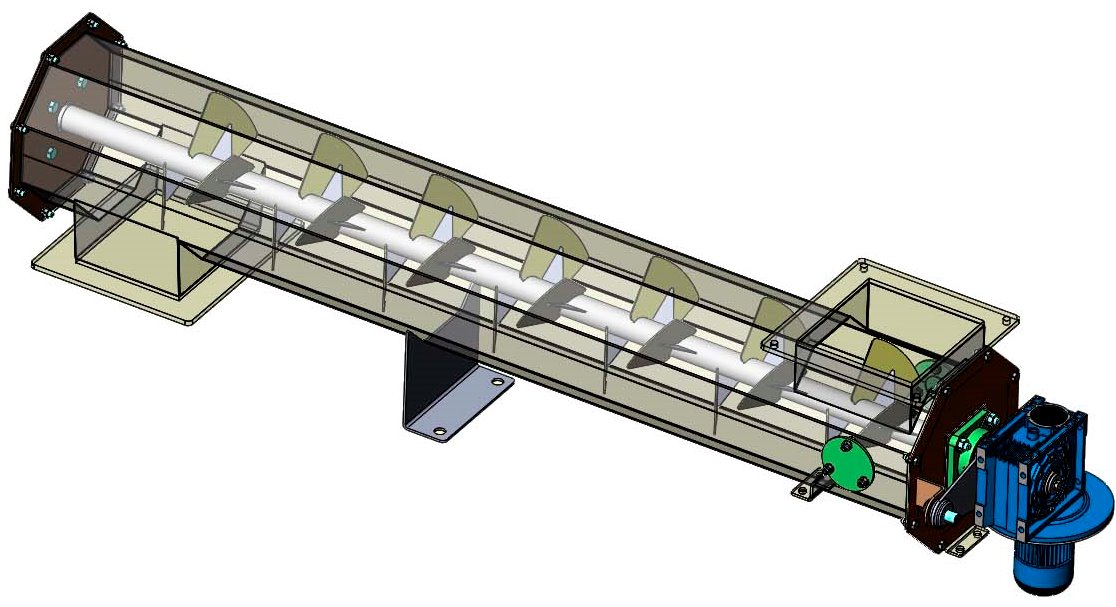

Excess moisture is fairly easy to remove during the cooling process in special coolers. Methods for checking and calculating pellet coolers are detailed in the article "Parameters for Effective Cooling"

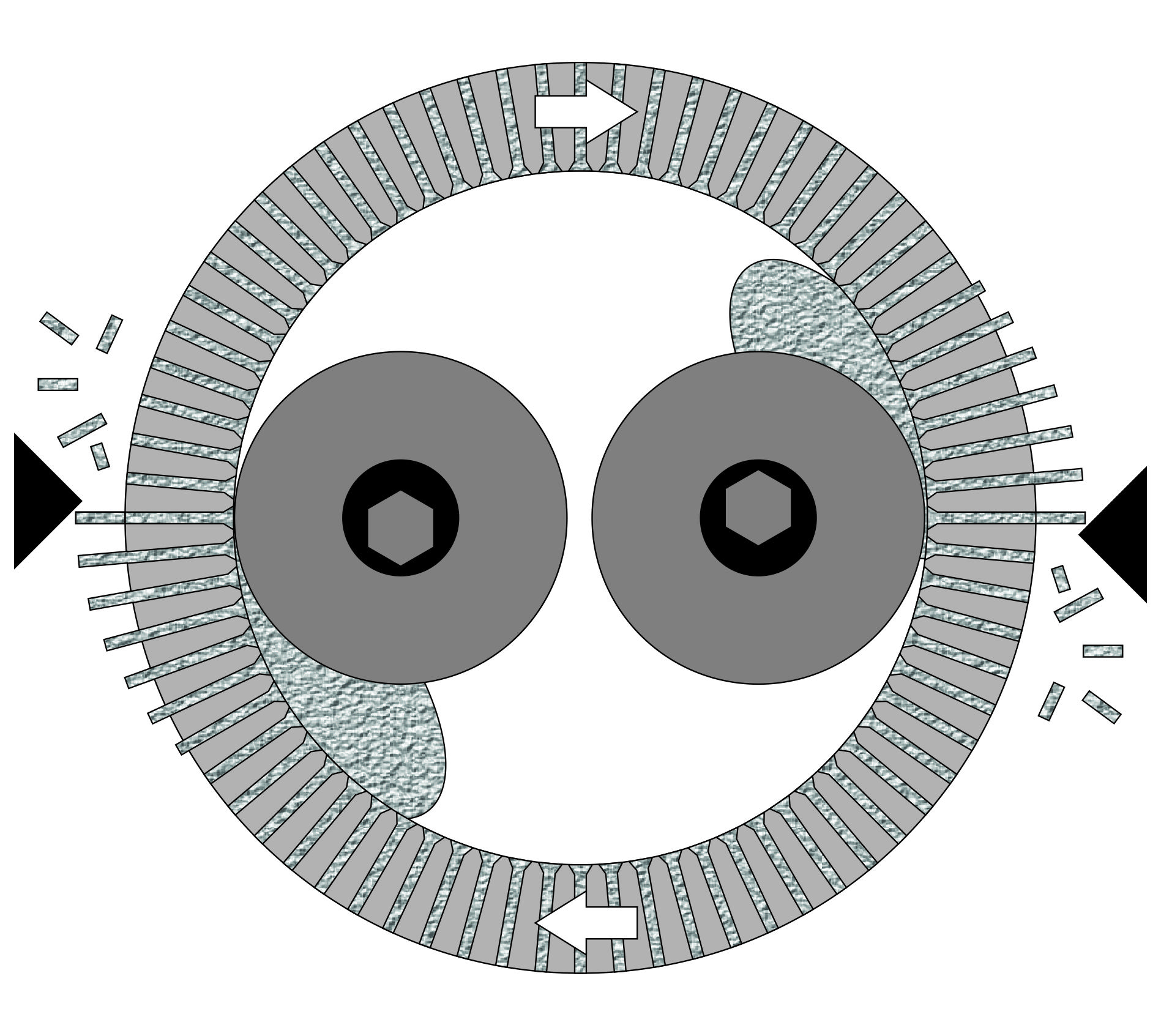

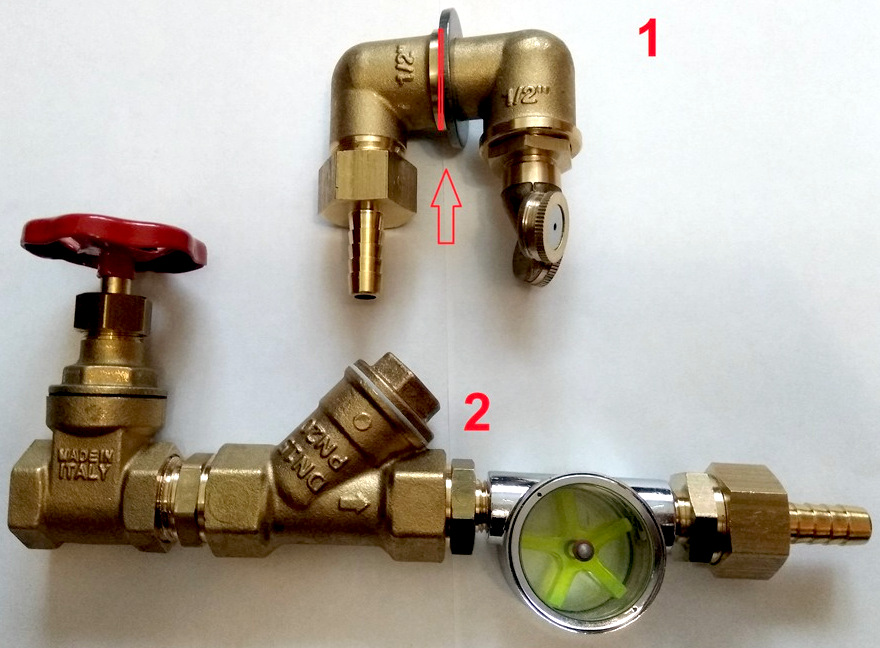

Visually determining moisture and quality of pellets immediately as they exit the pellet mill requires continuous operator attention. Installing a special sensor on the pellet mill door is very helpful, providing three signals: low, normal, and high moisture. The measurement happens in fractions of a second when the pellet is touched immediately after exiting the die, preventing die clogging during early overheating stages. The signal can be displayed using colored lights on the control panel or connected to an automatic moisture control system. Read more about moisture regulation in the article "Methods of Water Flow Regulation"