Brief answer: Pellets crack after the cooler due to too rapid cooling or improperly prepared material.

Symptoms of the Problem

- Cracks appear on pellets, although they come out of the pellet mill looking good.

- Lots of large particles are in the screening and clog the pneumatic transport and the sieve screen.

- The bulk density of pellets decreases.

Main Causes

- Too rapid cooling occurs when the small working volume of the cooler forces the use of a large airflow for cooling.

- Clumps of wet pellets in the cooler cause a reduced working volume of the cooler combined with increased airflow.

- Uneven fraction and moisture content of the material cause large and wet particles to transfer moisture to smaller particles, which swell and rupture the pellets.

Solution to the Problem

- Check if the working volume of the cooler matches the declared capacity.

- Inspect the internal cavities of the cooler and remove any wet clumps.

- Ensure adequate grinding before drying.

How to Avoid Repetition

Regularly check the condition of the cooler and the quality of cooled pellets, and use a hammer mill before drying when processing a mixture of sawdust and wood chips.

Expert Advice

Clumps form in the cooler cavity when it is turned off with insufficiently cooled pellets remaining. When finishing work at the end of a shift, keep the fan running for an additional 15 to 20 minutes once the last batches of pellets leave the pellet mill. If there has been a prolonged period of poor quality pellet output from the pellet mill with a high proportion of sawdust, unload the cooler completely after adjusting to produce high quality pellets to prevent clumping of still wet sawdust.

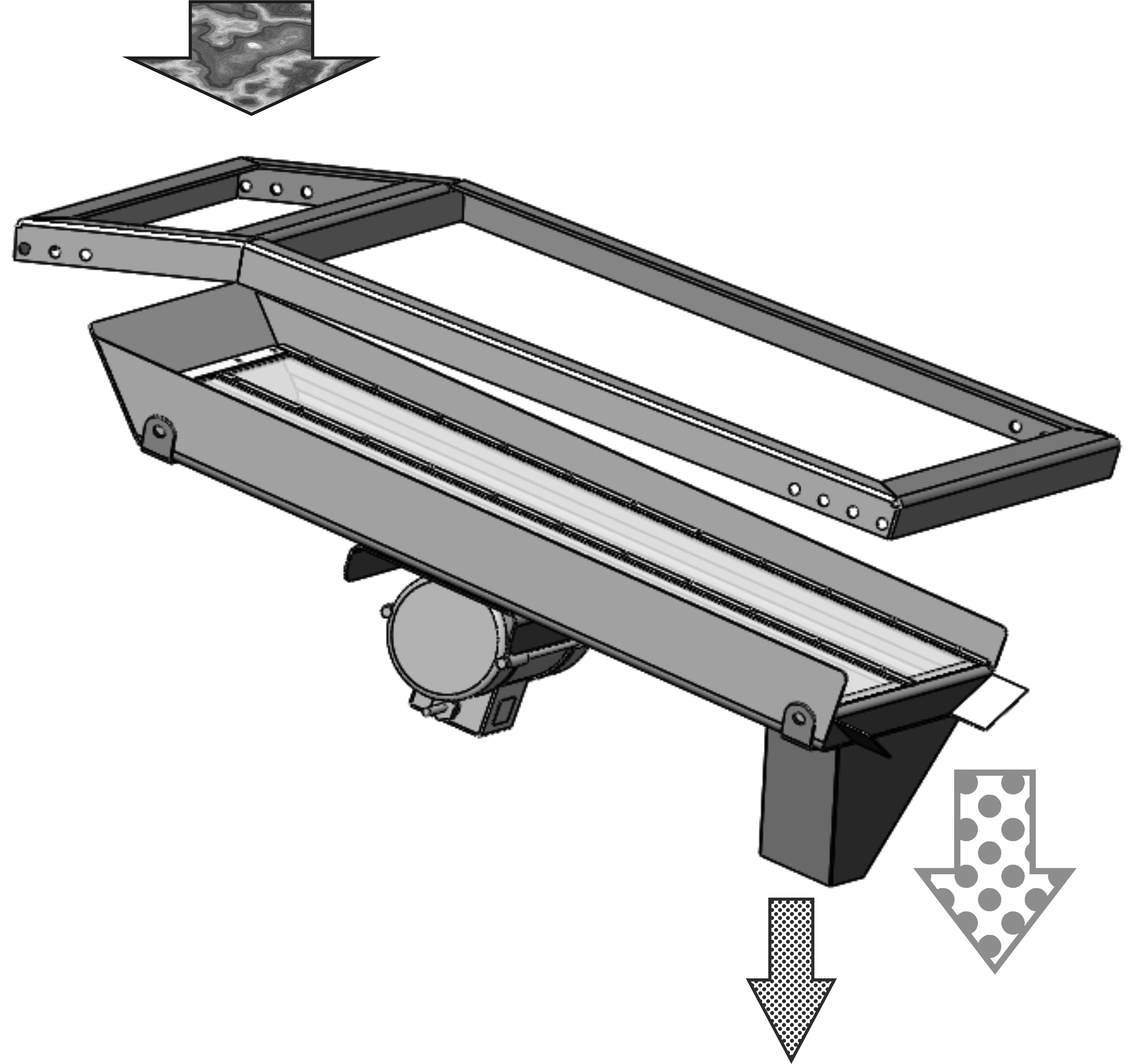

Before acquiring and launching a pellet cooler, find out the geometric dimensions of the cavity where the actual cooling occurs. Measure the exhaust air flow rate under stable operating conditions and reduce it with a damper if necessary. Read more about cooler calculations in the article "Parameters for Effective Cooling".

When processing material with varying moisture and fraction sizes, use a screenless hammer mill that easily processes wet wood chips to matchstick sized pieces or needle like particles. This ensures even drying and prevents the inclusion of wet fibers during further grinding of dried material in a screened hammer mill before pelleting. Read more in the article "Secondary Grinding of Wet Raw Material".