Brief Answer: Pellets crumble due to incorrect moisture content of the raw material or a worn-out die. To resolve this, check moisture, condition of the die and rollers, restore the countersink, and align the die track. Maintain optimal raw material temperature.

Problem Symptoms

- Pellets break during transport

- A lot of fine particles in bags or big bags

- Decrease in pellet density during storage

Main Causes

- Incorrect moisture of raw material — too dry or too wet material does not form strong pellets

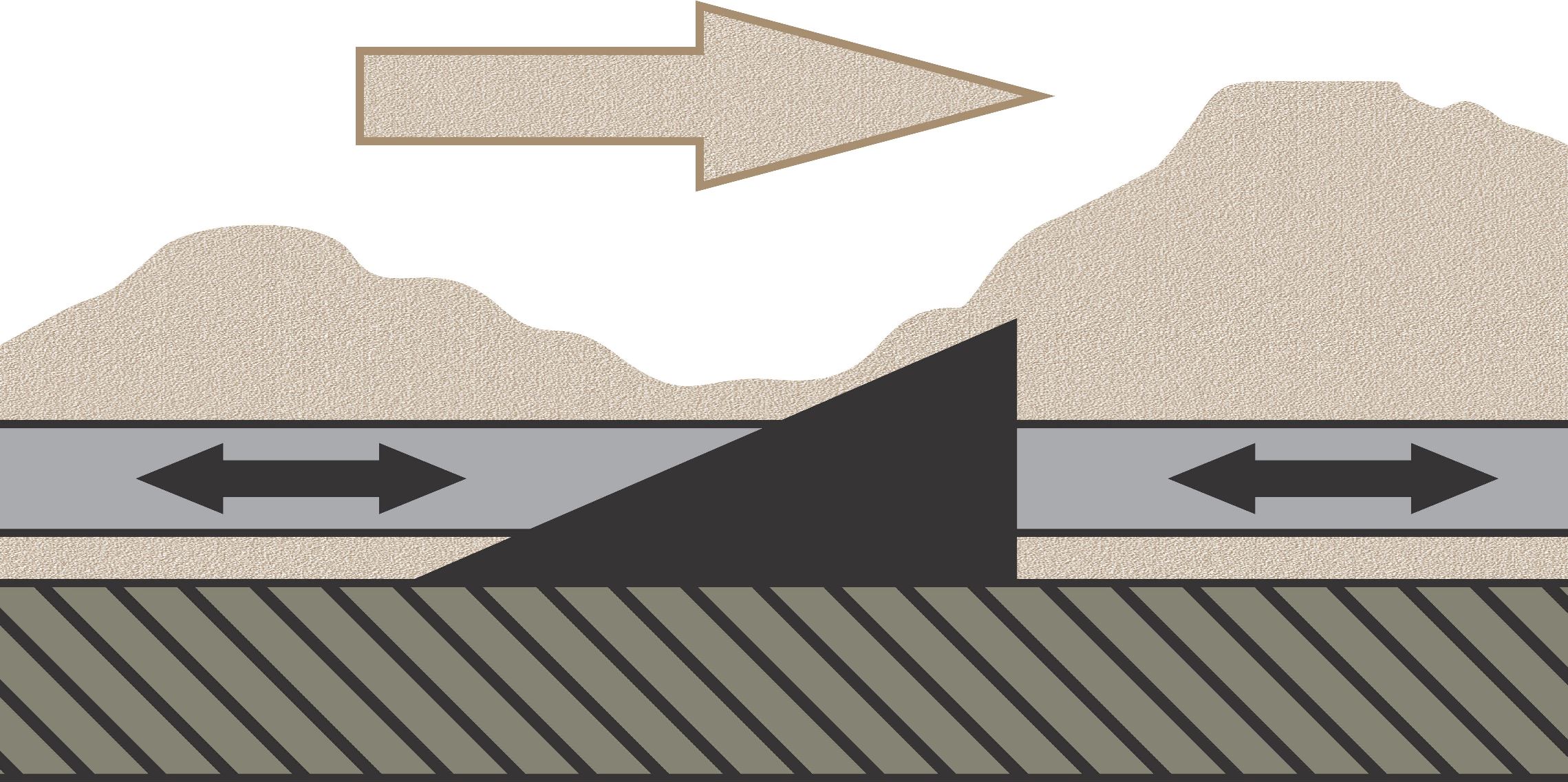

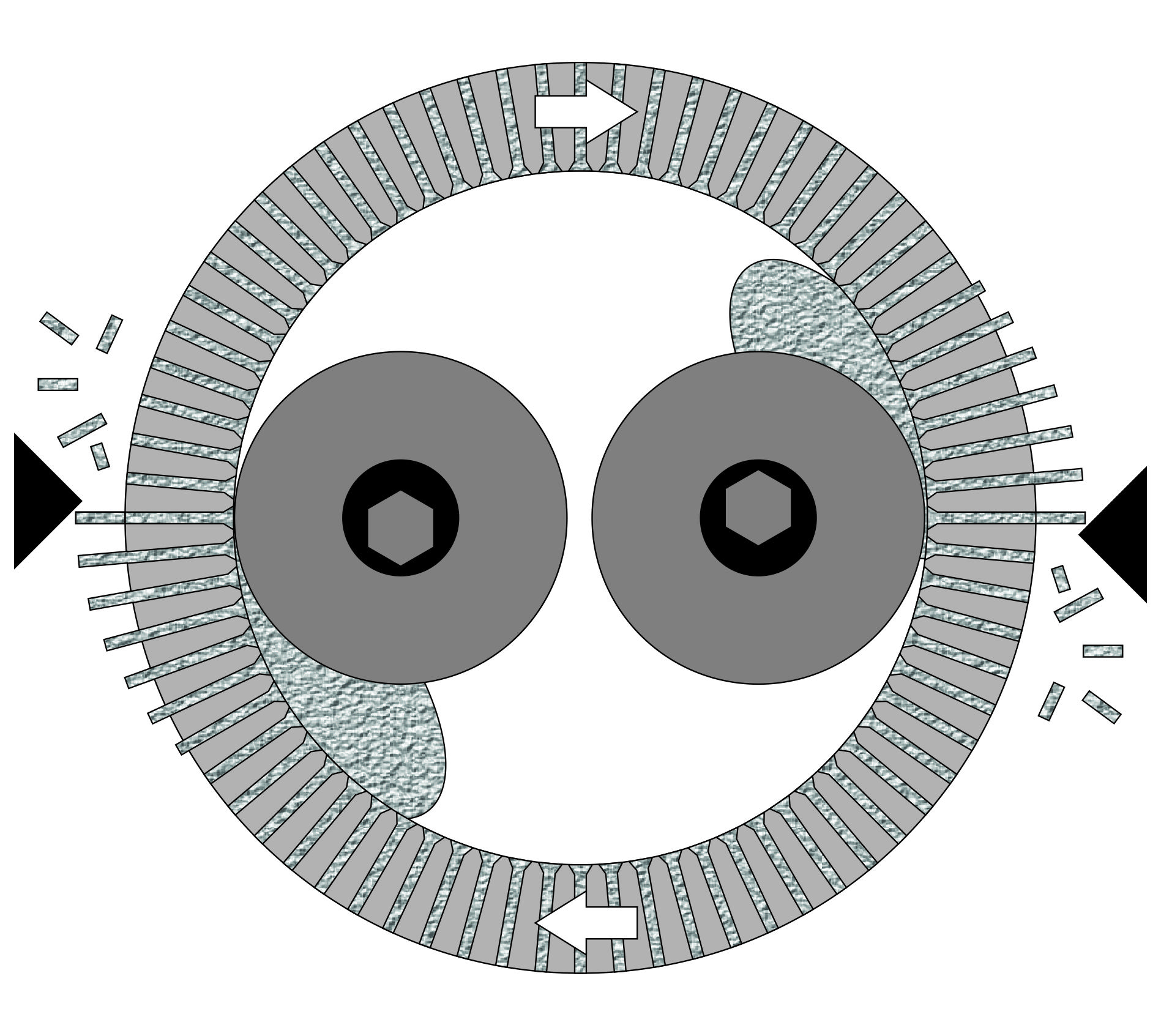

- Worn-out die — the working length of the ring die channel has become too short for quality pellet formation

- Incorrect die countersinking — the countersink angle is too large for this material

- Low pelleting temperature — underheating of the material reduces bonding

Solution

- Check and adjust the moisture content of raw material to 8–12%

- Inspect the die and rollers, and replace them if worn. For a new die, ensure that the working channel length suits your type of material

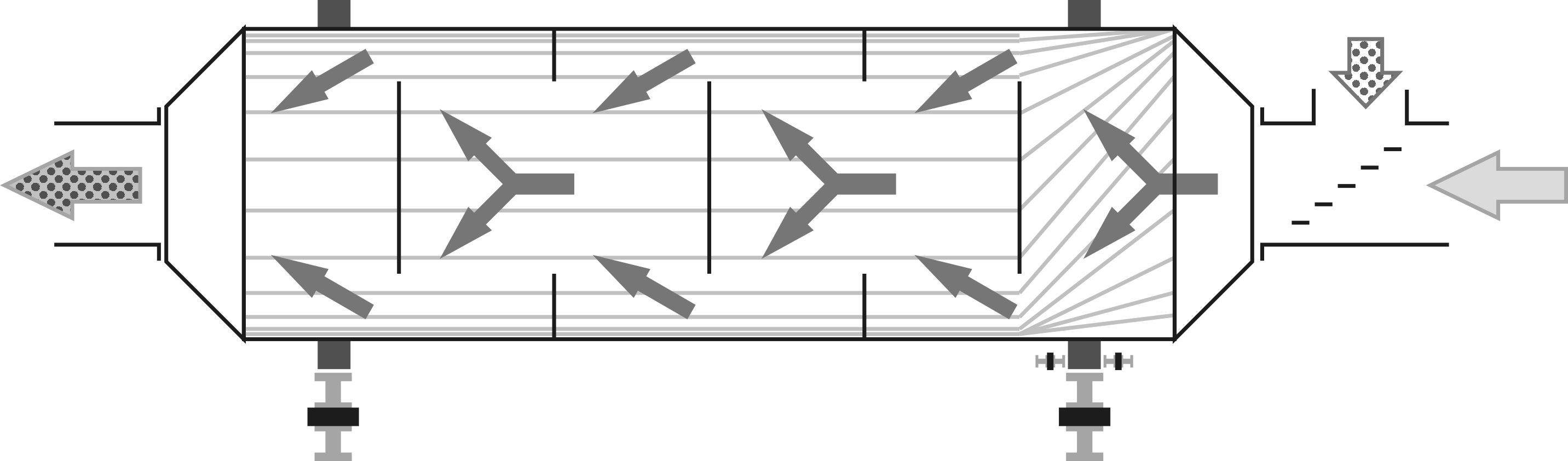

- Check the countersinking condition on the die track, and if there is peening or wear, align the track with a grinding tool and restore countersinking with feather drills

- Maintain a high temperature of the material exiting the dryer, avoiding prolonged intermediate storage

How to Prevent Recurrence

Use automatic temperature control at the dryer complex inlet and outlet to operate without additional water supply

Avoid starving the pellet mill: incomplete filling of the die track leads to uneven die wear and roller sleeve wear

Restore the geometry of the die track before installing new rollers for even gap

Keep the damping hopper empty so that warm raw material from the dryer goes directly into the pellet mill

Expert Tips

If pellets crumble suddenly, first check the moisture: in 90% of cases, this is the cause. For more details, read the article "Moisture of Raw Material"

If pellet quality decreases gradually, check the condition of the die and roller sleeves: gradual deterioration is due to wear. More details in the article "Working Length of the Die and Its Shape"

If quality deteriorates after starting or filling the bunker, adjust the dryer for changing moisture: the entry of snow or wet lower layers of sawdust drastically changes the drying process

Maintaining a high temperature of raw material facilitates wood bonding and reduces the load on the pellet mill, improving quality and increasing productivity. More details in the article "Fundamentals of the Pelletizing Process"