Maximum Allowable Ash Content Requirements

The requirements for the maximum allowable ash content of pellets according to EN Plus standards for the year 2022 are presented in the table:

| Quality Class | A1 | A2 | B |

|---|---|---|---|

| Ash Content on Dry Basis | ≤ 0.70 | ≤ 1.20 | ≤ 2.00 |

Wood bark contains several times more minerals than the wood of the same type of plant. For some species, this difference does not significantly affect the ash content of the final product, while for others with rather thick and mineral-rich bark, processing whole logs without debarking downgrades the granule quality to lower grades with less market value. The ash values are gathered from various sources and only show an approximate average picture. In reality, the biochemical composition of each individual tree varies widely depending on the climate and soil, even within the same region.

| Type | Pine | Spruce | Larch | Oak | Linden | Birch | Aspen | Poplar |

|---|---|---|---|---|---|---|---|---|

| Wood Ash Content, % | 0.27 | 0.35 | 0.22 | 0.31 | 0.52 | 0.45 | 0.58 | 1.63 |

| Bark Ash Content, % | 2.1 | 3.6 | 2 | 4.7 | 7.6 | 2.4 | 2.7 | 6.1 |

| Bark Proportion in Log, % | 11 | 9.5 | 18 | 21 | 14 | 13 | 14 | 16 |

| Pellet Ash Content, % | 0.47 | 0.66 | 0.54 | 1.23 | 1.51 | 0.70 | 0.88 | 2.35 |

As shown in the table, without debarking, oak, linden, and aspen cannot produce top-quality pellets. Meanwhile, poplar, as a prominent representative of fast-growing species, contains many minerals in its wood and is only suitable in its pure form for industrial-grade pellet production. Typically, when sawing logs, about half becomes usable lumber, and the other half remains as slab wood or chips. Therefore, the bark content in slab wood is approximately twice as much, with a corresponding increase in ash content. Only pellets made from pine slab wood meet the "premium" A1 class with allowable ash content up to 0.7%. Spruce, larch, birch, and aspen fall into the A2 class with an ash content limit of 1.2%, which restricts their use for certain types of boilers and slightly reduces market value.

| Type | Pine | Spruce | Larch | Oak | Linden | Birch | Aspen | Poplar |

|---|---|---|---|---|---|---|---|---|

| Wood Ash Content, % | 0.27 | 0.35 | 0.22 | 0.31 | 0.52 | 0.45 | 0.58 | 1.63 |

| Bark Ash Content, % | 2.1 | 3.6 | 2 | 4.7 | 7.6 | 2.4 | 2.7 | 6.1 |

| Bark Share in Slab, % | 22 | 19 | 36 | 42 | 28 | 26 | 28 | 32 |

| Pellet Ash Content, % | 0.67 | 0.97 | 0.86 | 2.15 | 2.50 | 0.96 | 1.17 | 3.06 |

In addition to the natural content of salts, dust consisting of clay and sand particles accumulates in the pores and cracks of the bark while still in the forest. Logging is also usually associated with contamination of trunk surfaces with soil, and frozen dirt often reaches the machinery. Studies at one enterprise showed that the ash content of contaminated bark is 2-3 times higher than after careful washing with water jets. Therefore, with low production standards, even pine logs might not yield top-quality pellets, and Spruce slabs might only produce pellets for coal power plants.

| Type | Wood Ash Content, % | Contaminated Bark Ash Content, % | Bark Share in Log, % | Log Pellet Ash Content, % | Bark Share in Slab, % | Slab Pellet Ash Content, % |

|---|---|---|---|---|---|---|

| Pine | 0.27 | 4.2 | 11 | 0.70 | 22 | 1.13 |

| Spruce | 0.35 | 5.2 | 9.5 | 0.81 | 19 | 1.27 |

Since soap-bearing washers have not been seen in the forest, bark is rightly blamed as the source of all troubles during waste processing and log sawing. Sand dulls saw and mill edges much faster, increasing sharpening costs and downtime. The best way to tackle this issue is to debark logs before cutting them into boards. The resultant bark, after further shredding, is useful as fuel for in-house boiler operations for kilns and other needs. It is also sold as mulch for gardens, raw material for extractive substances, and other industrial requirements.

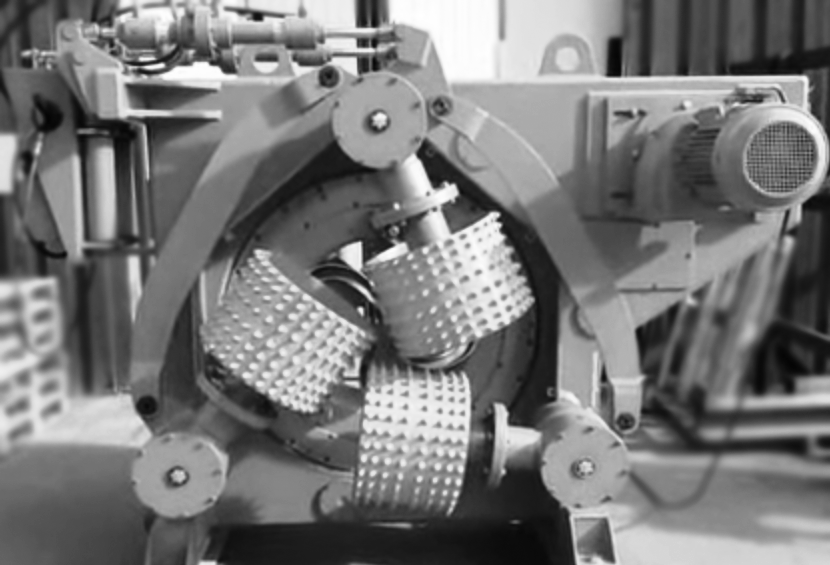

Rotary Debarker

This is the most efficient and effective type of equipment for debarking. The log passes through the center of a rotating rotor equipped with spring-loaded blades. The saber-like shape of the blades and their extensive stroke allow handling logs with uneven thickness from 80 mm (3 inches), bends, and other irregularities. The large blade stroke also ensures quality cleaning without prior sorting if the log diameters are within the machine's permissible limit. Log centering is achieved using two or three rollers, the positions of which are synchronized.

This is the most efficient and effective type of equipment for debarking. The log passes through the center of a rotating rotor equipped with spring-loaded blades. The saber-like shape of the blades and their extensive stroke allow handling logs with uneven thickness from 80 mm (3 inches), bends, and other irregularities. The large blade stroke also ensures quality cleaning without prior sorting if the log diameters are within the machine's permissible limit. Log centering is achieved using two or three rollers, the positions of which are synchronized.

High productivity is achieved by the circular arrangement of 4 or 6 blades, which remove a layer around the entire perimeter at once. The usual log feed speed is 0.7-1 m/s (2.3-3.3 ft/s), which is sufficient for supplying a sawmill line or a pellet plant with a capacity of about 10 tons per hour. Even though this is the most expensive type of debarker, replacing it with several cheaper machines would be more costly due to the complexity of the log handling system. The pieces of bark come out quite large, often in the form of curled shreds. This results in high efficiency and low specific energy consumption since there is no excessive grinding of waste.

Another advantage of this design is that the blades are not just in contact with the log but are always under the bark layer. This means their cutting edge is always in or near the cambium layer, and sand only occasionally reaches it. This explains the long interval between sharpening, which is about three months with round-the-clock operation.

Milling Debarkers

The principle of this machine is based on the rotation of the log while a rotating cutter moves along it, removing the bark layer with a planing knife. The productivity of the cutter is comparable to a single blade of a rotary debarker, but the safe rotation speed of the log is 2-3 times lower. If we also consider the time lost in log replacement, the average productivity is 5-7 times lower compared to a rotary machine, and specific energy consumption is higher due to the fine particle size of the waste. In addition, the high cutting speed on dirty bark causes rapid dulling of the knife.

The principle of this machine is based on the rotation of the log while a rotating cutter moves along it, removing the bark layer with a planing knife. The productivity of the cutter is comparable to a single blade of a rotary debarker, but the safe rotation speed of the log is 2-3 times lower. If we also consider the time lost in log replacement, the average productivity is 5-7 times lower compared to a rotary machine, and specific energy consumption is higher due to the fine particle size of the waste. In addition, the high cutting speed on dirty bark causes rapid dulling of the knife.

With relatively straight logs or those of small length, the logs are installed at a slant, ensuring they feed under the cutter while rotating. The through-feeding of logs eliminates time loss on replacement, making this solution effective for a pelleting line with a capacity of up to 1.5-2 tons per hour of finished product.

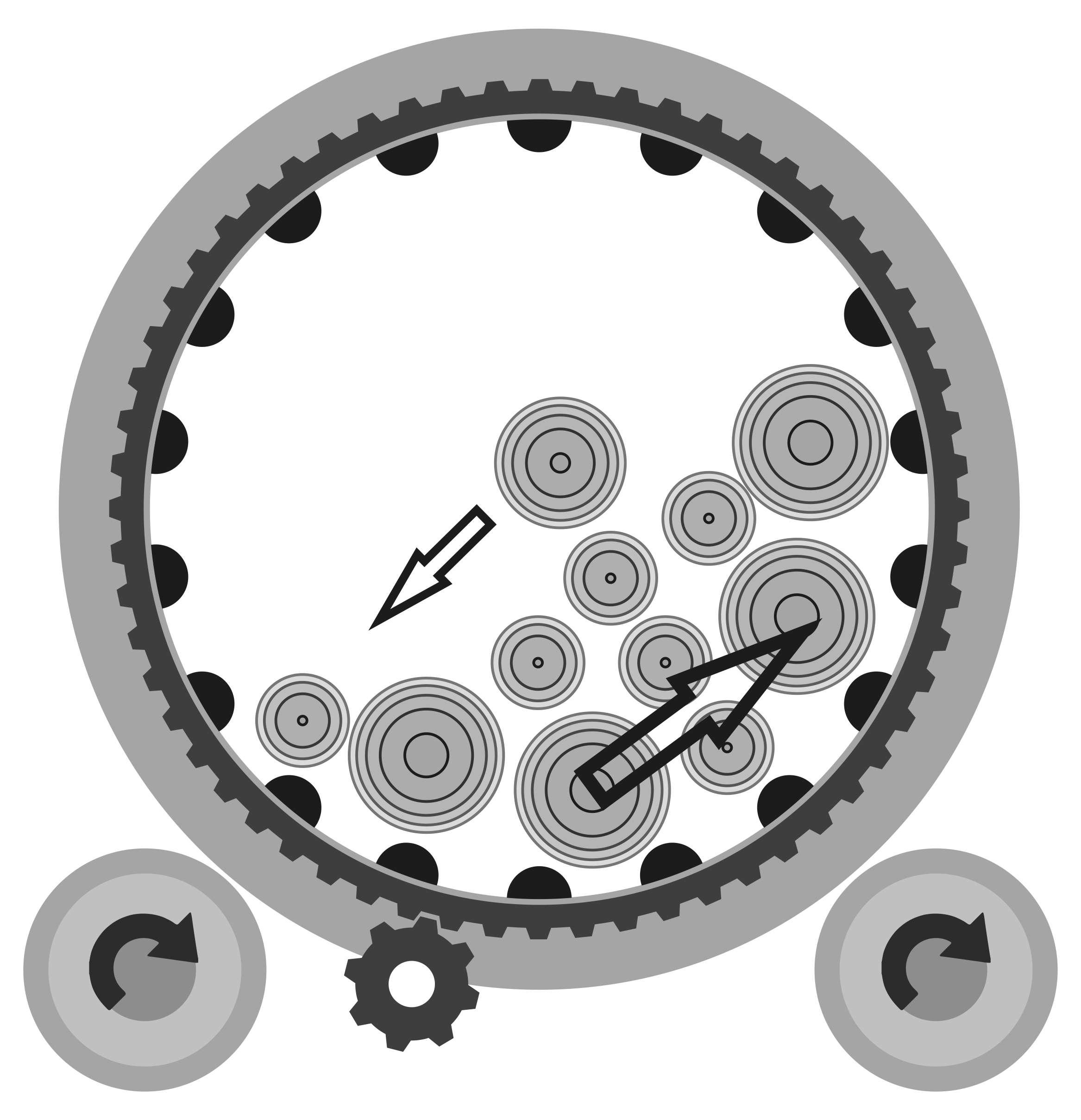

Drum Debarker

When it's sufficient to remove only the upper cork layer of bark along with contaminants for technological needs, a drum-type debarker is used. Its design consists of a cylindrical tube with a diameter from 1.5 to 5 meters (5-16 ft) and a length of 5 to 15 meters (16-50 ft), depending on the required productivity and trunk diameters. Inside, the surface is equipped with longitudinal semicircular ribs. As the drum rotates, the ribs ensure the mixing and rolling of logs, creating active friction and interaction between them. The process resembles a giant washing machine without water and soap. The drum is usually installed at an angle of 5-10° and logs pass through continuously. At the exit, a guiding trough helps orient the cleaned logs longitudinally onto a chain log deck, leaving a gap of 200-500 mm (8-20 inches) for bark to fall onto a discharge conveyor belt. Alternatively, a row of holes can be made on the drum's surface near the exit to remove fine particles.

When it's sufficient to remove only the upper cork layer of bark along with contaminants for technological needs, a drum-type debarker is used. Its design consists of a cylindrical tube with a diameter from 1.5 to 5 meters (5-16 ft) and a length of 5 to 15 meters (16-50 ft), depending on the required productivity and trunk diameters. Inside, the surface is equipped with longitudinal semicircular ribs. As the drum rotates, the ribs ensure the mixing and rolling of logs, creating active friction and interaction between them. The process resembles a giant washing machine without water and soap. The drum is usually installed at an angle of 5-10° and logs pass through continuously. At the exit, a guiding trough helps orient the cleaned logs longitudinally onto a chain log deck, leaving a gap of 200-500 mm (8-20 inches) for bark to fall onto a discharge conveyor belt. Alternatively, a row of holes can be made on the drum's surface near the exit to remove fine particles.

This method of bark removal is the simplest and most low-maintenance solution. The removable ribs and the wheels of the support stations bear the brunt of the load, with a lifespan of several years. Debarking is possible for a wide range of diameters and curvatures, as well as for cleaning stumps of soil and even logs with large branches.

When logs of very different diameters are fed simultaneously, or when the wood moisture content is low, the logs often break into several pieces, which can reduce the product yield for a sawmill. However, if the wood is intended for cellulose or biofuel production, this is the most effective solution in terms of waste-to-biomass ratio.

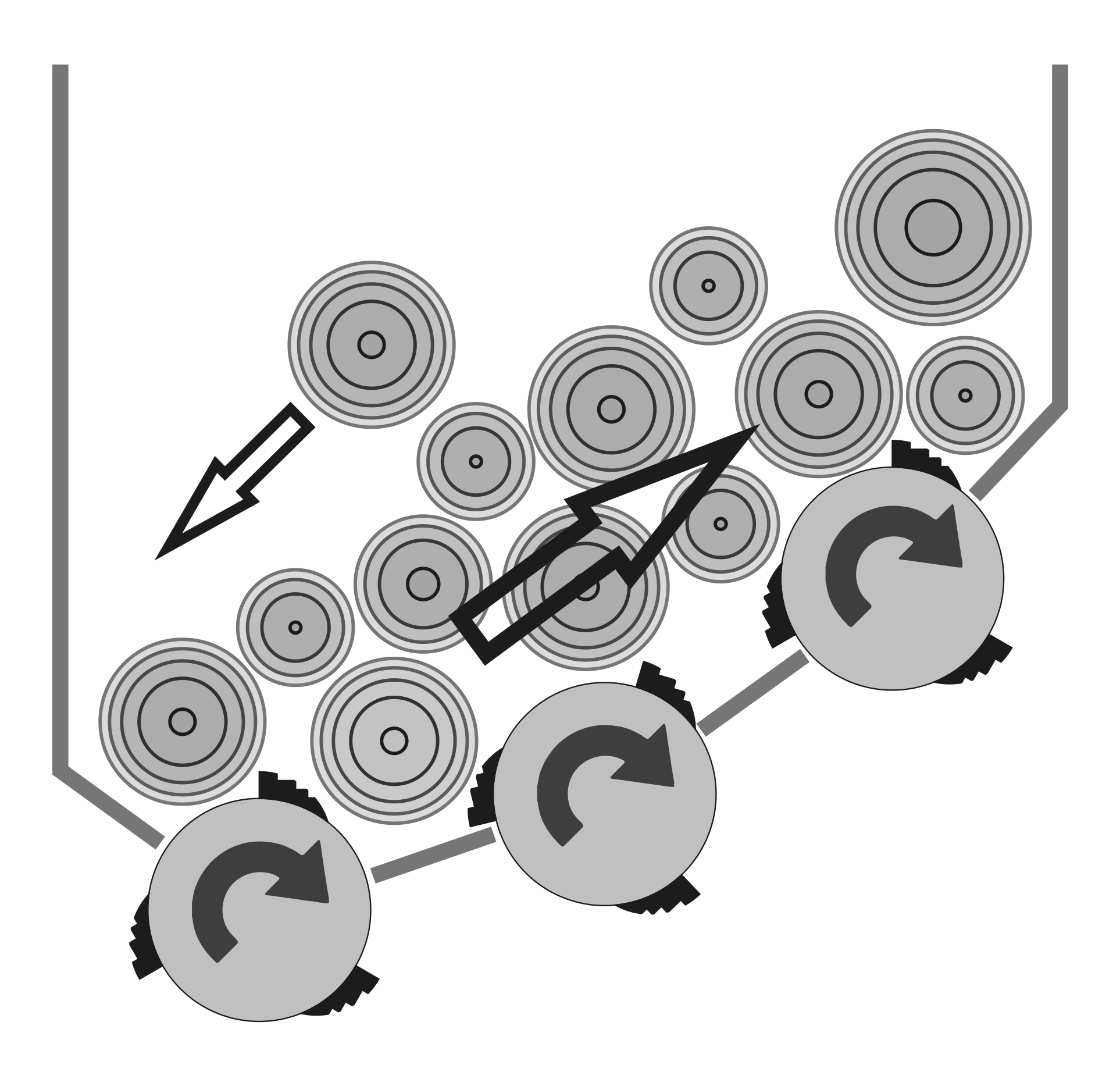

Roller Debarker

Not as massive as a drum debarker, but similar in its method of interacting with logs and between them, a roller debarker is also installed at an incline and actively mixes the incoming material. It tears the bark with catches and rotates the logs around their axis under the weight of the entire pile. From two to five longitudinal rollers are placed along the bottom of the trough. These rollers rotate in one direction, pushing the round wood upwards, from where the logs roll back toward the first roller and repeat the interaction path.

Not as massive as a drum debarker, but similar in its method of interacting with logs and between them, a roller debarker is also installed at an incline and actively mixes the incoming material. It tears the bark with catches and rotates the logs around their axis under the weight of the entire pile. From two to five longitudinal rollers are placed along the bottom of the trough. These rollers rotate in one direction, pushing the round wood upwards, from where the logs roll back toward the first roller and repeat the interaction path.

For the catches welded onto the rollers, slots are provided in the body through which the torn bark is removed. By changing the inclination of the body and the rotation speed, the intensity of the process can be adjusted. Just like with a twin-shaft shredder, a slight difference in rotation speed can either help to eject the logs into a pile or, conversely, allow the catches to penetrate deeper into the bark.

Such units are generally more compact and do not require chutes, conveyors, or hoppers for feeding the material. The open top allows logs to be loaded directly with a forestry truck manipulator. Unloading occurs by opening the side cover and engaging reverse rotation. The drawbacks include relatively rapid wear of the catches, which are recommended to be made detachable and surfaced with special alloys.

Slab Debarker

Much debate has been sparked over using slabs as acceptable raw material for more in-depth processing. Cutting boards from it generally does not cover worker wages, and its use for erecting walls and fences is unsuitable because the bark promotes rapid decay and pest breeding. A solution has emerged in the market: a pass-through type slab debarker. This machine uses a rotor with attached chains to knock off anything that does not hold well. The chains allow processing of uneven surfaces and, unlike a cutter, do not require sharpening. However, impact loads can lead to breakage, so protection at the entry and exit is mandatory.

The resulting material gains value as usable for construction but is unsuitable for the biofuel industry due to the high added cost. The feed speed of such a debarker is usually around 0.5 m/s (1.6 ft/s), and feeding a line at a rate of 1 ton (2,200 lbs) per hour requires at least three machines operating simultaneously. Increasing the number of machines significantly raises the cost of binding with conveyors and proportionally increases the number of laborers required. Increasing the width of the feed belt and rotor could solve the issue, but who can keep up with laying that many slabs bark-side up? Such a solution might be applicable in conditions where the pellet price is extremely high near the consumer, where somehow free slabs and cheap labor are available despite high demand for fuel.

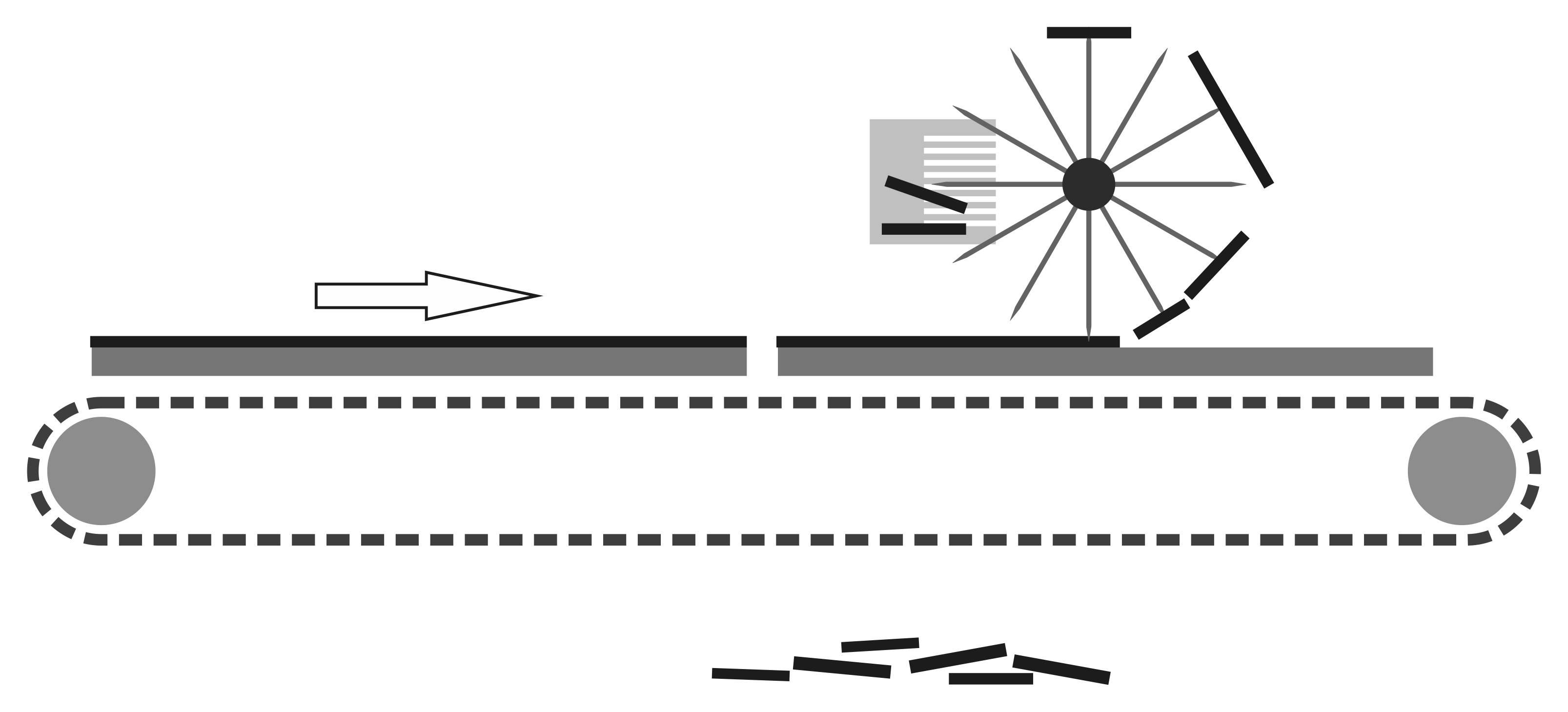

Bark Beetle

Sometimes well-known problems are solved in very unconventional ways. As it is known, wood damaged by bark beetles allows the production of low-ash pellets because the bark along with dirt falls off during the harvesting and transportation process. This beneficial trait of the pest is utilized at a facility where there used to be a huge accumulation of slabs due to no demand for high-ash pellets. Fresh slabs are stored in a separate hangar where the bark beetle multiplies. Severely beetle-damaged logs, unsuitable for cutting, are also brought there. Within 2-3 months due to larval activity, the bark barely clings to the slabs and is removed by a hedgehog-like device installed over the conveyor that feeds the wood chipper. The bark is then scraped off the hedgehog with an inclined "comb" next to the conveyor, so the task of the wood chipper operator is simply to place the slabs with the bark side up to produce white pellets from waste material. Since some of the bark falls off during feeding and dense pricking every half-meter (1-2 feet) is sufficient, a single worker can handle the feeding function.

Sometimes well-known problems are solved in very unconventional ways. As it is known, wood damaged by bark beetles allows the production of low-ash pellets because the bark along with dirt falls off during the harvesting and transportation process. This beneficial trait of the pest is utilized at a facility where there used to be a huge accumulation of slabs due to no demand for high-ash pellets. Fresh slabs are stored in a separate hangar where the bark beetle multiplies. Severely beetle-damaged logs, unsuitable for cutting, are also brought there. Within 2-3 months due to larval activity, the bark barely clings to the slabs and is removed by a hedgehog-like device installed over the conveyor that feeds the wood chipper. The bark is then scraped off the hedgehog with an inclined "comb" next to the conveyor, so the task of the wood chipper operator is simply to place the slabs with the bark side up to produce white pellets from waste material. Since some of the bark falls off during feeding and dense pricking every half-meter (1-2 feet) is sufficient, a single worker can handle the feeding function.

It is noteworthy that with constant feeding, the beetles do not hurry to fly away. Regular processing of slabs along with the larvae and unfavorable conditions for overwintering sharply limit the beetle's reproduction capabilities. Using the separated bark as fuel also leads to the destruction of fallen larvae and curbs the beetle invasion.

You Might Also Like

Important! All information on this website is for informational and recommendation purposes only! Before making changes to the settings and structure of the equipment, be sure to consult with the manufacturer, ensure the safety of your actions, and just in case, consider how to return everything to its original state.