The entire variety of raw materials can be roughly divided into four types:

- Feed mix and ingredients

- Biomass for fuel purposes

- Fertilizers based on peat or manure

- Technological additives for industrial use

Feed Mixes or Compound Feed

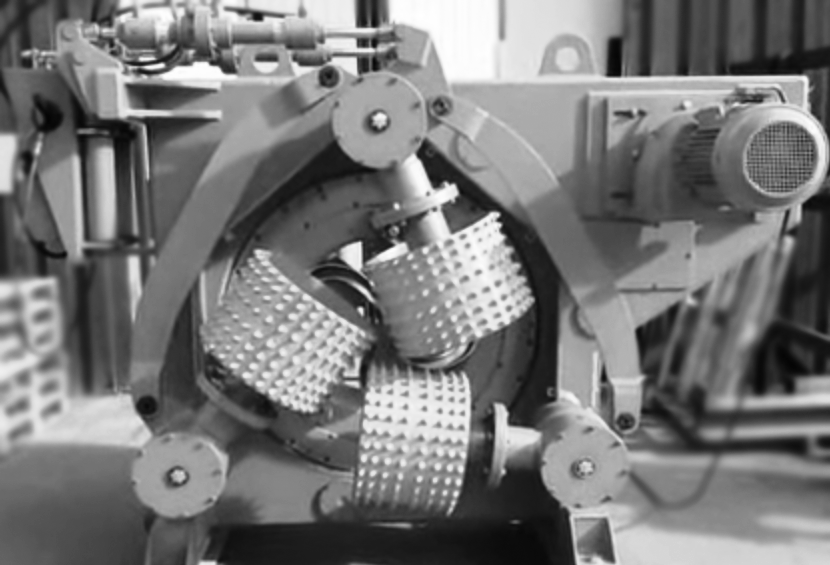

Feed mixes or compound feeds are the most massive sector in the pelletizing topic. Granulation is applied to both separate types of waste from various food productions, aiming to give them better technological properties, as well as ready-made mixes with a complete composition for feeding different animals. If you compare the prices of the initial composition ingredients and the finished feed, the prospect of fabulously getting rich becomes apparent. However, such production has two pitfalls. Firstly, the presence of an ingredient contaminated with some dangerous fungus in a batch of goods can lead to mass animal deaths on a farm and huge losses, which may possibly be joyfully shifted onto the feed producer. Secondly, such productions must not only have perfectly tuned internal production logistics but also be very flexible in terms of different recipes. A simply gigantic system of storage silos for grain, premixes, meal, and other additives is needed, against which the pelletizing shop occupies only 5-15% of total investments. Special attention should also be paid to the materials from which the equipment is made, its ability to work on food-grade lubricants, and the possibility of fully cleaning and sterilizing individual parts to prevent contamination by harmful microflora.

It should also be taken into account that depending on the recipes and the purpose of the compound feed, up to 10 types of dies with different die diameters and working channel lengths may need to be put into circulation immediately. Such a set of dies can be comparable in price to the price of the pelletizer itself but will allow for quick production adjustments based on market demands.

Biomass for Fuel Purposes

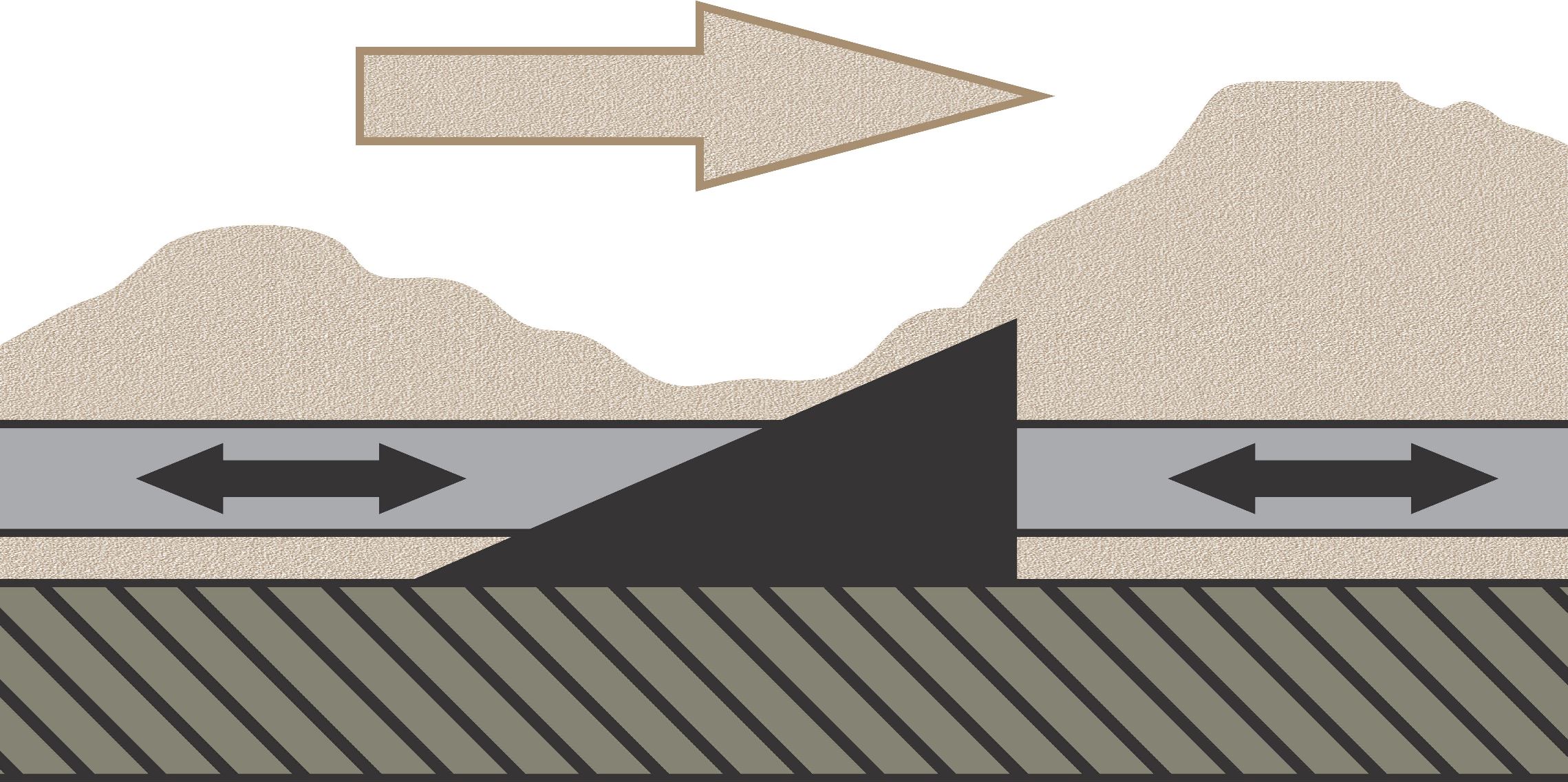

Fuel-purpose biomass is a relatively new direction that has emerged with the development of "green" technologies to reduce carbon emissions. Primarily, these are either agricultural processing waste like husks or straw or various wood waste in the overwhelming majority of natural moisture. For processing the husks of various crops, a simple pelletizing section is usually sufficient. In the case of dry straw granulation, an additional bale and bundle shredder may be required, which does not complicate the process too much. The processing of raw wood is the most laborious and complex process because the line includes the maximum number of units subjected to significant loads. Some units are more prone to the influence of moisture and weather conditions, others to biochemical composition, and others to periodically occurring foreign impurities in the raw material. A common mistake is trying to apply feed-grade equipment to wood processing. The matter is not just in selecting the appropriate die for the pelletizer but also the noticeably greater mechanical loads during crushing and pressing. Moreover, raw sawdust and chips are very prone to bridging in bins and hoppers, and at freezing temperatures, they freeze on screws, in ducting, and other hard-to-reach places. This usually leads to frequent stops and highly unstable operation of the pelletizing line in general.

Fertilizers Based on Manure or Peat

Fertilizers based on manure or peat are a very effective solution as they are usually produced in pellets with a diameter of 4 or 5 mm, which can be applied using ordinary grain seeders. Fertilizer applied in pellet form slowly releases ingredients into the soil, achieving several important goals:

- Practically eliminates "burning" of roots by nitrates

- Minimal leaching into groundwater

- The effect of application is observed over 3-4 years

- Humic acids restore depleted soils

- Correction of the chemical composition is possible depending on the soil's acidity and other properties.

Features of manure processing:

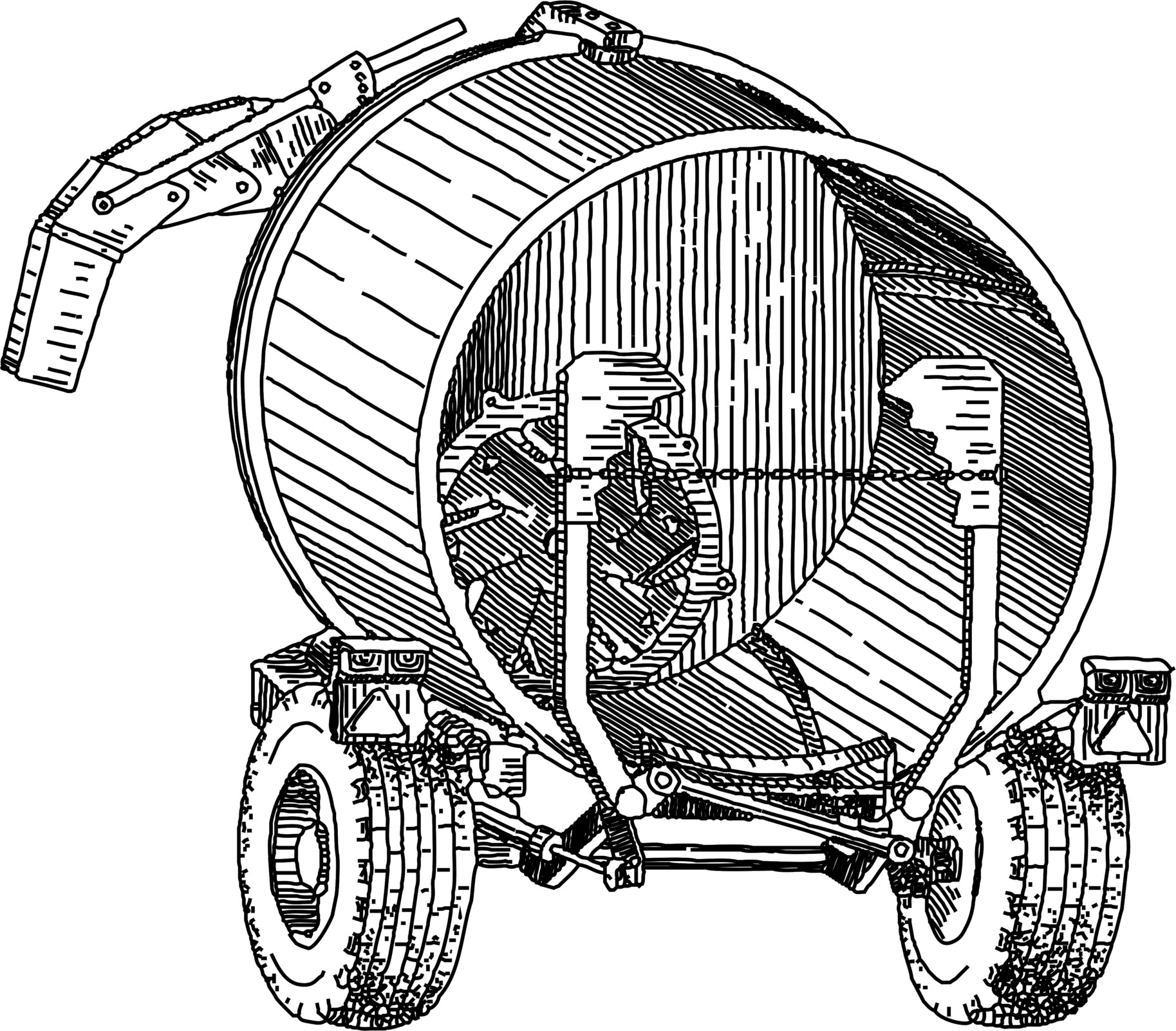

- The raw material is mostly obtained from farms and factories, where it is removed using belt conveyors or is washed away, so it is a semi-liquid substance. Before drying, it needs to be pressed, for which continuous screw separators are used, resembling industrial juicers.

- Bedding manure often contains gravel and stones, which lead to rapid wear of crushers and the die of the pellet mill, so special attention must be paid to cleaning the raw material.

- Drying manure by classical methods using dryer drum or belt dryers results in the release of a large amount of gases into the atmosphere with an extremely unpleasant odor, which is not only non-ecological but also hazardous to health. Therefore, the air cleaning system can become noticeably more expensive than the drying complex, or it will be necessary to use so-called vacuum batch dryers, from which harmful gases are immediately disposed of in the heat generator furnace.

- To obtain complete fertilizer, it is necessary to add additional minerals and substances that reduce acidity, bring the NPK ratio to the ideal, and provide other important technological and biochemical properties. Often, phosphate rock powder, dolomite flour, nitroamophoska, and straw ash are used as additives. The additives need to be ground to a size smaller than 0.2mm and mixed in the correct ratio. This requires additional equipment, for which space should be planned in the production facility, considering logistics for storage, movement, and supply.

Industrial Technological Additives

Industrial technological additives are the most diverse in terms of composition and purpose. In foundries, granulated graphite is used to introduce relatively pure carbon because in a loose state, it is extremely difficult to supply and mix. Granulated aluminum powder is used for the same purpose. Rubber crumb is granulated to obtain a special additive in asphalt materials, which improves the wear resistance of the coating and its grip with car tires. For stabilizing asphalt coverings, granules made from asbestos or cellulose fibers are introduced. The feature of producing such additives is that bonding occurs through the diffusion of materials with each other or by melting components directly in the pressing unit of the pellet mill.

There are also many other materials that simultaneously fit different categories. If a wooden fuel pellet is produced with moisture at the upper limit, it absorbs water and various solutions much faster. This type of pellet is used as a filler for cat litters or as an industrial absorbent.

Sometimes the composition is complicated to achieve the maximum result. For example, a mixture of wood bark with waste paper is suitable for toilet filler. Cellulose fibers promote the fastest absorption, while tannins in the bark provide chemical bonding of ammonia and block unpleasant odors. Similar properties are exhibited by a mixture of clay, wood flour, and hard mineral acids, from which 4mm diameter granules are produced for certain valuable animal breeds.

RDF or Refuse-derived fuel

RDF or Refuse-derived fuel a relatively new direction is the production of fuel from sorted household waste. The small pieces of plastic packaging, cardboard, textile fibers, and food waste left at the end of the conveyor, after automatic cleaning of stones and metals, become valuable raw materials. Pellets made from this mixture have twice the calorific value compared to wood pellets. The most crucial aspect of such production is to prevent the inclusion of halogen-containing organic substances and heavy metals in the fuel. The largest and most frequent problem is polyvinyl chloride, widely used in the production of goods and packaging. It is responsible for the emission of dioxins. Contrary to the negative perception of plastic packaging, burning regular polyethylene mixed with cardboard is quite eco-friendly and causes significantly less environmental damage compared to coal-fired power plants. Without proper removal of organochlorines, such fuel is limited in its use to cement production and other kiln operations, where the resulting dioxins are quickly neutralized by the binding of chlorine ions with heated minerals.

RDF or Refuse-derived fuel a relatively new direction is the production of fuel from sorted household waste. The small pieces of plastic packaging, cardboard, textile fibers, and food waste left at the end of the conveyor, after automatic cleaning of stones and metals, become valuable raw materials. Pellets made from this mixture have twice the calorific value compared to wood pellets. The most crucial aspect of such production is to prevent the inclusion of halogen-containing organic substances and heavy metals in the fuel. The largest and most frequent problem is polyvinyl chloride, widely used in the production of goods and packaging. It is responsible for the emission of dioxins. Contrary to the negative perception of plastic packaging, burning regular polyethylene mixed with cardboard is quite eco-friendly and causes significantly less environmental damage compared to coal-fired power plants. Without proper removal of organochlorines, such fuel is limited in its use to cement production and other kiln operations, where the resulting dioxins are quickly neutralized by the binding of chlorine ions with heated minerals.